IIoT Data Management and Analytics for Manufacturers

Data-driven manufacturing and IoT predictive analytics solutions aren’t new in manufacturing, and making decisions on the basis of clear and accurate figures isn’t a new strategy. However, data-driven manufacturing is still not widespread enough to make sure that each and every production facility works in this new data-driven reality.

Are you following a data-driven approach to decision-making? We suggest you answer three simple questions:

- When was the last time you made a data-driven decision when updating the way your manufacturing company operates?

- Are you sure you get the most out of the data your workers provide you with to optimize your operating costs and workflows?

- Do you follow the latest trends in technological solutions for large manufacturers?

If you have trouble answering these questions, then:

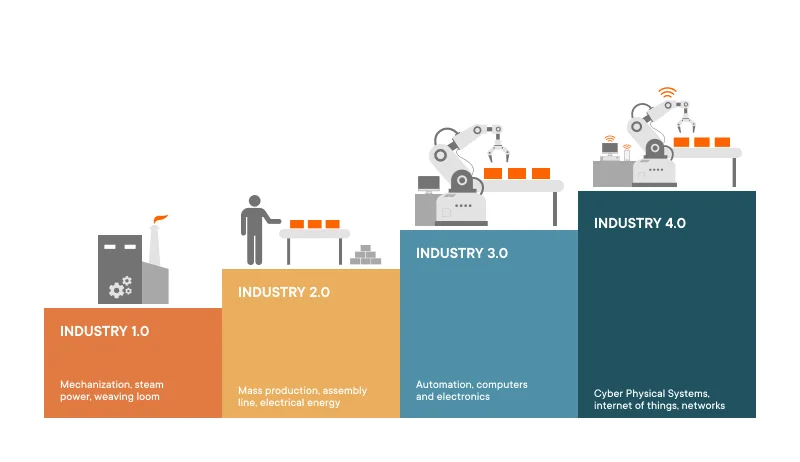

- Your business might still be in the Industry 2.0 state (whereas we’re now moving to Industry 4.0) and you urgently need to change this.

- You’ve found the right article: here you will find a proven way of optimizing your manufacturing processes by using data correctly

Read also: How to ensure IoT-based predictive maintenance for your manufacturing company

Industry 4.0: Brief and concise

Today, computers can mimic human decisions and independently cope with the maintenance of huge manufacturers:

*A cyber-physical system (CPS) is a computing system that controls and monitors a network of sensors, equipment, and machines and connects them to the virtual space.

As witnesses of the fourth industrial revolution (or Industry 4.0), we can see how Industry 4.0 has brought artificial intelligence (AI), robotics, industrial automation, machine-to-machine communication (M2M), and the internet of things (IoT) with IoT services and predictive analytics into more widespread use.

However, ordinary IoT devices and IoT analytics platforms aren’t designed for industrial purposes and aren’t suitable due to their limited power. This has led to the introduction of Industrial Internet of Things (IIoT) devices, which can be successfully applied at large production facilities. IIoT devices are predominantly powerful sensors, actuators, and controllers that function in a large network. For example:

- Vibration sensors

- Temperature sensors

- Security sensors

- Humidity sensors

- Proximity sensors

- Gas sensors, and more

The valuable IIoT benefits are clearly seen after the data they generate reaches its final destination. Such final destinations can be industrial IoT data management software solutions, which work as data hubs and guarantee data aggregation, processing, and transformation.

In our previous article, we discussed how IoT suppliers can build industrial IoT software to attract new customers with detailed explanations of what to consider and why while developing them.

Check out how we built a SaaS device management platform for an IoT supplier.

In today’s article, we will discuss:

- what benefits IIoT data management software can bring to operating facilities and their management

- how IIoT software solutions differ from traditional ones

- what you should pay attention to when choosing among different platforms

Let’s start our journey.

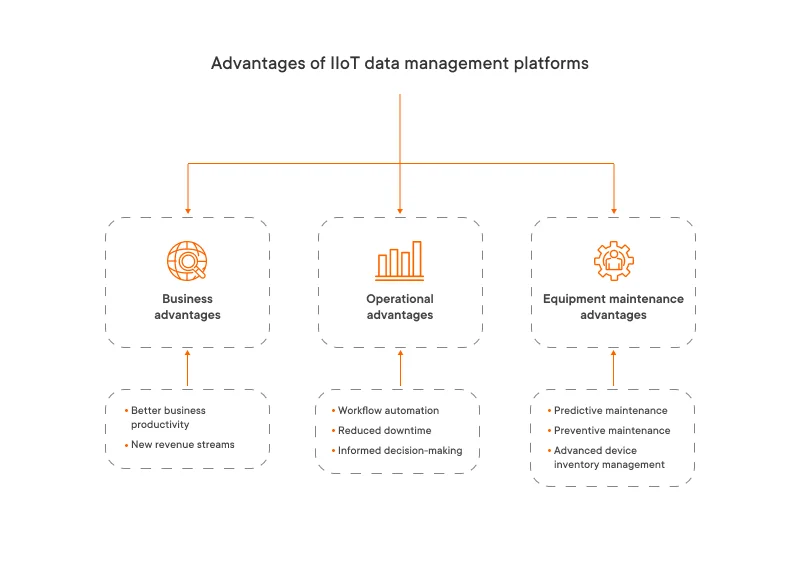

How industrial data management platforms can facilitate and optimize the operation of large manufacturers

The ultimate goal of industrial data management platforms is to provide manufacturers with valuable insights regarding the work of either specific production facilities or the whole production chain. These platforms work with Industrial Internet of Things big data. Accordingly, it requires industrial data analytics and advanced and IoT analytics approaches (that we will discuss later) to provide proper information to workers and management. If they are implemented properly, you will get the following:

Business advantages

Better business productivity

IIoT data management platforms instantly share important data with anybody engaged in the overall management of your plant.

How? Besides powerful sensors that continuously send massive amounts of data, manufacturing companies have various departments that give information on an everyday basis. Production, quality, sales and purchasing, environmental health and safety, technical planning, accounting, and so on generate different types of data that, one way or another, influence the way a manufacturer operates. IoT consulting company can help to effectively implement systems and ensure smooth integration for all departments involved.

After your data management system gets data from all departments, it switches on the system’s data processing center. The data processing center, in a matter of seconds, analyzes data coming from all sensors, equipment, and departments. As a result, workers get a report on what’s going on at the production facility from all possible angles and at any moment.

Result: As the output, you get all data compiled into an all-in-one report with a data summary and recommendations to ensure smooth operation of a production facility.

Value: You will be able to control any operational processes at your production facility and optimize them even in the middle of the process without delays. This will lead to improved efficiency, greater productivity, and a better work experience.

New revenue streams

An IIoT data management platform can help you discover new revenue streams.

How? Multiple departments will use an all-in-one solution. Marketing, sales and purchasing, and quality assurance will enrich your database with unique insights on:

how customers use your products (as intended or not)

- frequently emerging issues with products

- unnoticeable benefits of your products that customers have discovered and shared with the support team (that can be used in future advertising)

Value: You can:

- use this data to innovate a product according to customers’ needs and, in this way, attract more customers

- extend your advertising campaign with insights from real consumers

- use financial insights to create new monetization models that will be more convenient for your potential customers and more beneficial for you

Operational advantages

Workflow automation

IIoT data management systems are advantageous for production facilities in terms of automating operational and decision-making processes and contributing to implementing data automation technology for manufacturing.

How? All units of your data management platform present valuable information regarding:

- visualizing the condition of equipment under certain circumstances (before the working session, in the middle of it, afterwards, and during scheduled or urgent maintenance)

- monitoring general workflows at the manufacturer with detailed analysis of people’s decisions made under various circumstances (such as regular manufacturer operations, unplanned downtime, and accidents)

Result: With artificial intelligence (AI) and machine learning (ML) technologies, IIoT data analytics and management platforms can:

- study and analyze different use cases

- remember actions of personnel inside the system in specific situations

Value: Your data management platform will be able to:

- independently control the manufacturer’s work (including equipment) with minimal personnel involvement

- take appropriate measures automatically and on time to streamline workflows, prevent accidents, or resolve issues with equipment, premises, or production

Reduced downtime

An IIoT platform can help avoid unplanned downtime and set up a smooth operating process.

How? The platform can monitor the situation with the help of information collected by sensors located throughout the production facility. It can analyze different gauges and make predictions regarding possible downtime due to leaks, problems with pipes, ventilation, and so on.

Result: By monitoring the conditions of premises on a daily basis, the system can identify conditions that gradually go beyond the established limits or peaks and send notifications or trigger built-in alerts.

Value: By reacting to such signals in a timely manner, production workers can prevent unplanned downtime that might affect overall facility operations.

Informed decision-making

IIoT data management platforms can powerfully enrich your production facility’s potential and improve its operational processes.

How? Information coming from sensors and equipment is analyzed and provided to workers and managers in the form of reports.

Result: Reports aren’t just raw figures that you have to decipher by yourself. An IIoT data management system applies complex analytical approaches not only to analyze what it sees but also to give conclusions, warnings, or advice. Sometimes, it even reacts by notifying workers of necessary actions. To ensure that all data and communications are secure, IoT security services help protect critical operational data from external and internal risks.

Value: The system automatically remembers everything, specifically your actions inside the system, and can repeat these actions automatically in the future without your assistance.

Equipment maintenance advantages

Predictive maintenance

You can solve many problems with your equipment by using IIoT devices and implementing industrial IoT predictive analytics..

How? Everything is under the control of one system. Workers get real-time data regarding equipment conditions and can initiate urgent maintenance or repairs in an emergency.

Preventive maintenance

With an IIoT data management platform, you can make sure your equipment gets necessary maintenance on time.

How? Unlike predictive maintenance, preventive maintenance is done according to a schedule. With the help of a unified device control system, workers (or the system itself) can control planned repairs or updates as well as monitor the quality of their implementation.

Advanced device inventory management

Keep track of all the machines used at your production facility.

How? An IIoT data management platform can be integrated with third-party services that are responsible for machines and equipment at your facility — for example, machine vendor platforms. By exchanging data with them, your platform can let you know when a new piece of equipment is available and can be put into use. Also, the system will notify you of when it’s time to update a machine’s operating system or firmware.

However, is everything really as great as it sounds? Unfortunately, together with the astonishing results that an IIoT data management platform can give you, there are a few challenges you have to consider.

First and foremost: to buy or to build?

Ready-made solutions vs custom platform development

If there are already products by industrial IoT analytics companies, is it worth developing your own product from scratch? To be honest with you, there’s no definite answer.

As an experienced software IIoT engineering company, we can tell you this: it depends on your goals. Never believe a strict yes or no.

To begin with, you need to evaluate each of the platforms that more or less suit you. Find out their pros and cons, see how they apply advanced methods of IoT data analytics, and only then decide whether they meet your business requirements. It’s not just about the out-of-the-box functionality or pricing. Also consider:

- Will the platform be able to satisfy your growing business needs?

- Will you be able to adapt it to new processes?

- Will it be able to perform new types of IoT data analysis?

- How often will you get updates?

Custom development is beneficial in that the finished platform will fully meet your needs. It will be created taking into account:

- the specifics of your production

- the specifics of the data that sensors collect

- how you want to filter, process, visualize, and analyze data

In the future, such a platform will develop in parallel with your business and adapt flexibly to new business needs and goals. Data engineering services help structure and streamline the flow of data from various sources, ensuring that your platform is capable of scaling effectively over time.

If you’re one of those who prefer looking into the future and won’t accept the option of moving from one platform to another, then you should prioritize custom development. See our expertise if you want to know how we create custom IoT software solutions for manufacturing companies.

However, how can you make sure your platform has the most crucial elements?

IIoT data management platform development: What to consider

The IIoT world brings new challenges to building IIoT data management platforms because of the peculiarities of data coming from IIoT devices. Unlike working with traditional IoT devices, working with production-level IoT devices introduces a completely new perspective on data and how to use and collect it.

What makes IIoT platforms different from IoT platforms and influences a manufacturer’s way of working

Let’s start from the very beginning.

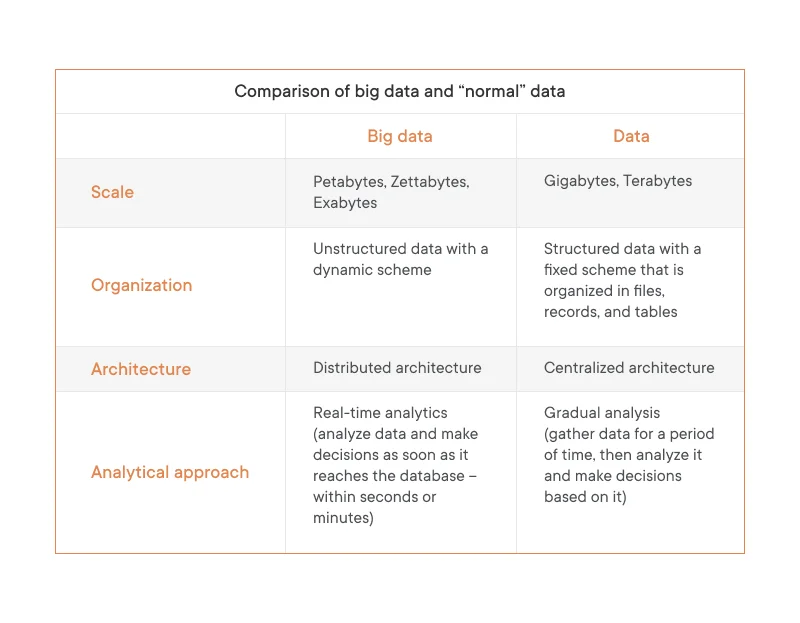

You will have to deal with new data volumes. The amount of data received from IIoT devices is incomparable to that generated by IoT devices. Powerful machines and sensors send tremendous amounts of raw analytical data generated each millisecond.

To be more precise, when we’re talking about IIoT devices, we’re talking about IoT and big data. To get a clear picture of what big data is, look at the table below:

When developing an IIoT data management platform, you should consider the peculiarities of big data analytics for IoT in manufacturing, as creating a platform for manufacturing requires specific approaches and domain expertise. The amount of data a platform handles influences the choice of methods for data retrieval and storage.

Luckily, huge amounts of data are no longer a big challenge. Big data solutions such as Apache Hadoop, Google BigQuery, Databricks Lakehouse Platform, and other solutions help you easily collect and transfer any amount of data.

However, in addition to big data volumes, it’s important to take into account the following:

- Data velocity, which covers such aspects as the speed of incoming data, its lifespan, and the speed of its storage and retrieval

- Data variety, which encompasses different types and formats of data

- Data veracity, which deals with the accuracy of the data received

- Data value, which is the importance of received data in a particular operation

- Data variability, which is concerned with data consistency

All these together give us an idea of what large manufacturers should look for when they’re considering using IIoT data management platforms: the ability of the platform to smoothly deal with large amounts of unstructured data and provide high-class real-time big data analytics (RTBDA).

How is this possible?

Building a solid technological background for an IoT data management and analytics solution

When developing an IIoT data management platform, it’s necessary to take into account the means of collecting data, storing it, and creating conditions for its rapid, almost instantaneous analysis.

The first step is to build a robust data collection and storage environment. For this, we turn to known means along with some new ones.

Data management options

Here we will turn to concepts already known to us, such as data lakes, databases, and data warehouses. In this article, we will focus on their pros and cons in terms of data management for IoT devices, but you can read more about their common usage in another article.

The main criteria by which we will evaluate these concepts are their purpose, agility and accessibility, and IIoT data processing speed, as they are crucial when we’re talking about data coming from Industrial Internet of Things devices. Let’s take a closer look:

Not reaching 100 points doesn’t mean that these types of data management are bad. They can be successfully used for storing historical data, reporting, and basic analytical operations, which can be conducted in the background.

However, what should you do to facilitate real-time big data processing?

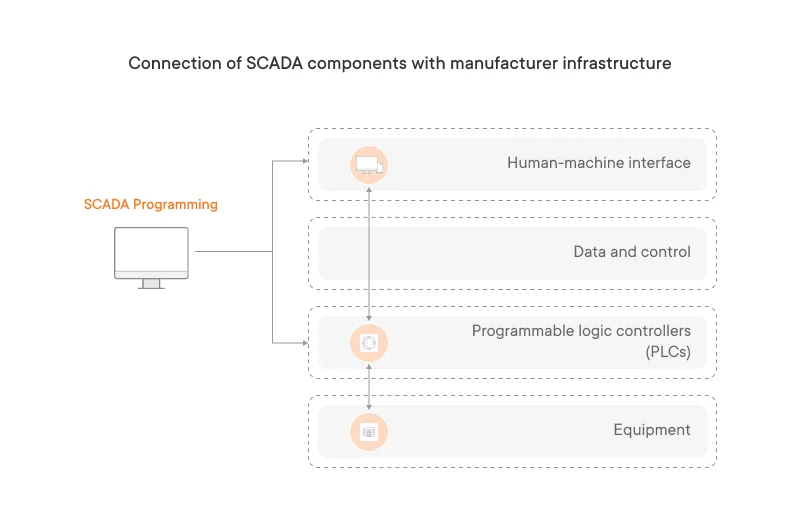

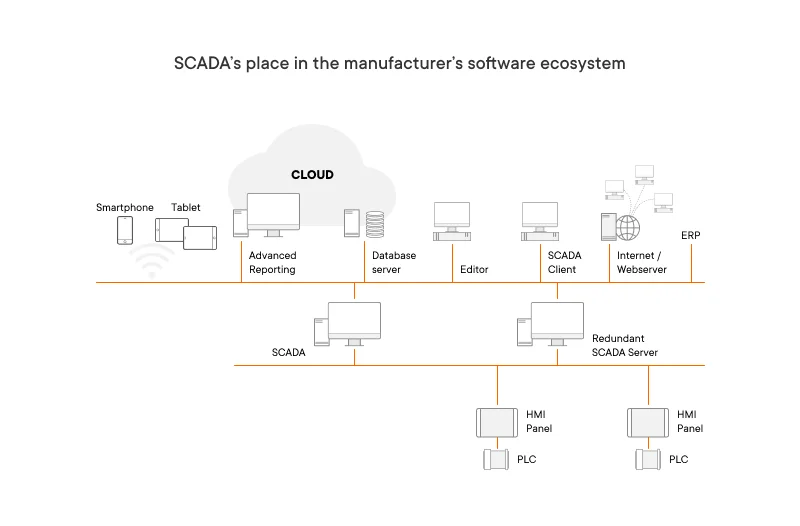

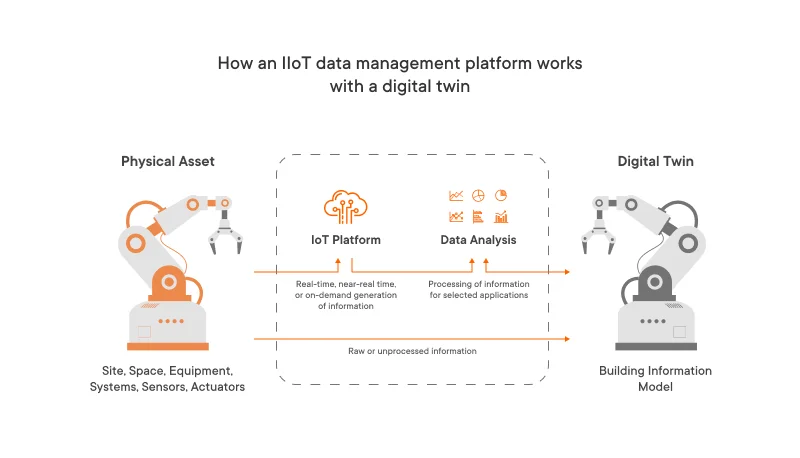

In working with IIoT platforms that aggregate and process data for manufacturing purposes, developers also integrate with two technologies that provide invaluable support for the operation of such systems and contribute to IoT data analytics and visualization. These are SCADA and digital twins.

Their advantage is that they collect data not only from sensors but also from the equipment. This way, you will have everything at your plant under your control, starting from the entrance and finishing with the smallest sensor.

Let’s learn more about SCADA and digital twins.

What are SCADA and digital twins?

Supervisory Control and Data Acquisition (SCADA) is a control system architecture. In simple words, it’s a software application that helps control and monitor industrial operations. Its main purpose is to gather data about the equipment and production facility’s internal conditions and constantly monitor them. Data gathered using SCADA is stored in the SCADAMOM database.

Usually, SCADA involves hardware elements such as programmable logic controllers (PLCs) and remote terminal units (RTUs). They gather data from sensors. One of the inevitable parts of SCADA is a human-machine interface (HMI) that helps workers communicate with machines and equipment and shows real-time machine data.

SCADA’s advantage is its ability to control local and distributed (cross-facility) plant floor equipment and sensors. That’s why such systems are used in spheres like energy and infrastructure, transportation, building, and automotive.

Why integrate with SCADA?

First, SCADA makes data gathered from sensors and equipment immediately available and ready for Industrial IoT analytics.

Second, integration with SCADA gives you more control not only over external conditions at the plant (temperature, vibrations, pressure) but also a more complex picture of the equipment’s inner workings. This will result in in-depth monitoring of the production facility.

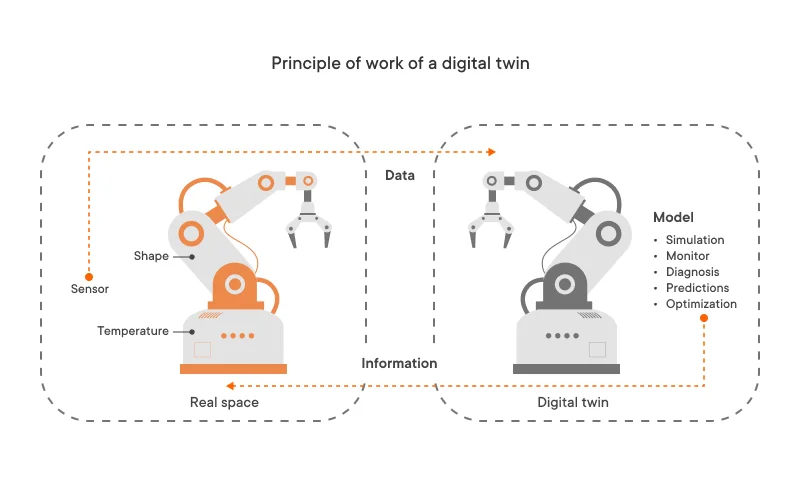

Digital twins. A digital twin is a visual representation of a machine. An IIoT data management platform constantly updates data for a digital twin to process it and digitally represent how the equipment works.

Digital twins are a great supplement to SCADA.

Why use a digital twin?

First, a digital twin goes beyond simulations, which are often used to forecast accidents or downtime. A digital twin uses actual data and provides a real-time visualization of the equipment’s condition.

Second, SCADA is good. But it’s good at gathering data, giving access to data, and allowing us to use data in any way possible. It won’t make any modifications or calculations on its own. A digital twin can do this with the help of artificial intelligence and machine learning as a service. The combination of these solutions within your IIoT data management system will provide you with necessary and valuable output.

Read also: How Yalantis built a big data analytics platform for a logistics company

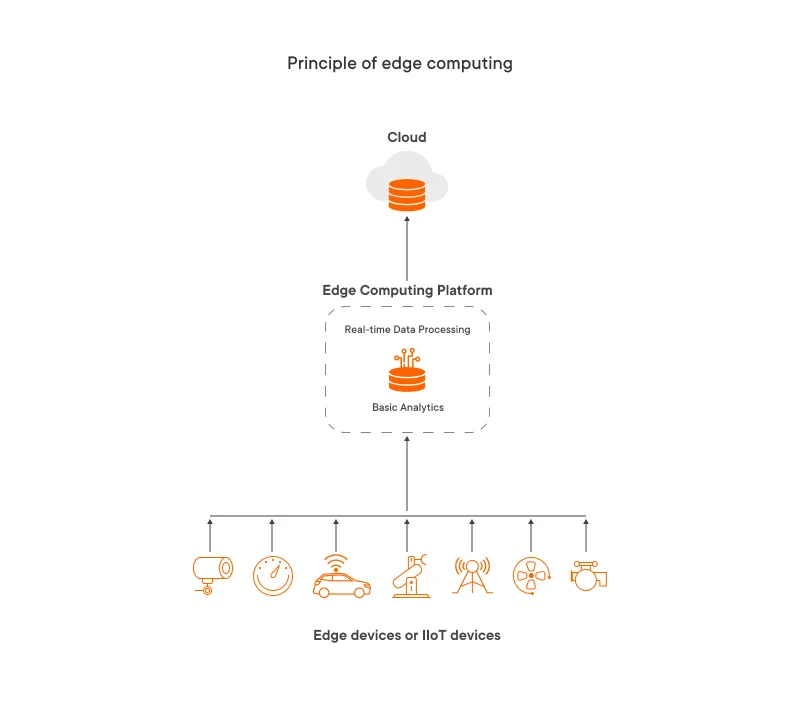

When we’re talking about gathering data in the IIoT world, it’s important to do everything that will contribute to quicker and more efficient data aggregation and consequent processing. The principle of Wi-Fi can be applied here: the closer you stand to the wireless router, the better the signal you have and the better the internet connection you enjoy. Similarly, the closer the processing center is to the device, the faster you will get data. This is how edge computing works.

Edge computing in combination with edge analytics for IoT

We usually mention cloud computing when we talk about analytical platforms, which means that all data collection, processing, storage, computing, and analytics for IoT take place in the cloud. This helps you to work more flexibly with data as well as reduce the resources spent on infrastructure.

On the other hand, when it comes to constant work with physical devices that produce a huge amount of data, we need to move to edge computing. The concept of edge computing is that Internet of Things data collection and processing don’t take place in the cloud but closer to the physical data source. Edge computing has several advantages:

- reduces response times

- reduces operating costs (because it doesn’t require additional infrastructure)

- gives better control over data

It’s worth mentioning edge analytics in the context of working with data closer to devices. If edge computing is a method of working with data closer to physical devices, then edge analytics is engaged in the analysis of the received data, the results of which are then sent to the platform.

Read also: How Yalantis built a real-time data analytics platform

We have discussed how we can aggregate data and process it. Now it’s time to talk about data security.

Data security

Data management platforms consist of many applications that have their own areas of responsibility. Furthermore, each manufacturer has its own hierarchy of access to specific types of information. In addition, different types of data can be used in different types of IoT analysis in many applications within the same platform, which means a constant exchange of confidential data (IoT application development services). Based on this, apart from the unique manufacturer-specific security mechanisms, it’s necessary to take into account the following requirements which fall under the ISO 27001 standard:

- Data encryption, which allows you to transfer and store data in an encrypted form so that it’s not possible to steal confidential information

- Multi-factor authorization, which prevents unauthorized entry into the system but also provides additional guarantees of secure access to the system

- Role-based access control (RBAC), which restricts access to certain information to people who shouldn’t see it

- Single sign-on (SSO), which allows you to authenticate with various components of the program using a single ID

So far, we’ve discussed data aggregation and protection. Now it’s time to shed some light on the analytics itself.

Three big data analytics techniques that are currently a must for an IIoT data management platform

The analytical component is one of the most important parts of a data analytics platform. IoT big data analytics based on data taken from IIoT devices requires special approaches and advanced analytic solutions.

The technologies your IIoT data management and analytics system can’t exist without include:

Artificial intelligence and machine learning

Given the huge flow of data in a large manufacturing facility, having an electronic system that can make decisions on production operations on the same level as a person can be indispensable. The following technologies will help you with this:

- Artificial Intelligence. AI is gradually becoming an integral part of the work of analytical platforms, as they have gone beyond automatic data processing. Analytical platforms are already advising us based on analyzed data and forecasting possible downtime, repairs, and loads.

- Machine learning, on the other hand, comes to the defense of workflow automation. This includes equipment maintenance, constant monitoring, and reporting. For example, instead of wasting time on time-consuming repairs, a machine learning component can make sure workers perform routine maintenance on equipment to minimize downtime. In addition, it can remember what actions were performed in specific situations.

With an IIoT data management solution implemented, you won’t have problems with how to connect your enterprise management strategy with your IIoT analytics results. They will work for you on their own thanks to AI and ML.

Read also: How to optimize supply chain costs and increase the customer acquisition rate with ML

Business intelligence

Business intelligence encapsulates strategies and technologies for IoT data analysis. These strategies and technologies include data mining services, querying, data preparation, reporting, benchmarking, descriptive analytics, statistical analysis, and visualization.

We’ve discussed lots of things, but we can’t forget about the people who are working with data management systems. As you’re building a product for them, you should consider aspects that touch upon virtual workspace convenience.

Advanced UI/UX with customizable dashboards

The user interface is one of the most important parts of any solution, especially when the main work tool is data. IIoT data management platforms often contain sets of different applications that each serve a specific purpose. A data management and analytics platform is used by a large number of specialists, who work with different types of data and perform various analytical operations on it.

What’s important to consider in this case is customization and an intuitive approach. Customization will serve as a good helper for those who want to filter different types of data and build separate dashboards for different cases. An intuitive approach will make the platform a convenient work environment, as employees will not need to go through a long process of onboarding and learning the platform’s features.

Summing up

IIoT data management platforms are becoming an integral part of the work of large manufacturers. When working with a huge amount of equipment and sensors that monitor the situation at a plant, a person can’t physically keep track of everything and establish smooth operations. IIoT data management platforms are capable of doing much of the human work that involves monitoring production facility performance. The result is more efficient, more stable, and quicker overall operations. However, it’s not possible to build something of high quality without an experienced software engineering company. Be wise when choosing one to work with. We can offer you team augmentation services for your IoT project (IIoT services). Explore one of such cases if you are interested in such type of services.

FAQ

How can a manufacturer benefit from industrial IoT data analytics?

By effectively implementing IoT and state-of-the-art analytics technologies, manufacturing companies benefit from improved productivity and uptime, increased process and operational efficiencies, spurred innovation, decreased asset downtime, full visibility of operations, decreased operating expenses, and enhanced machinery effectiveness.

What is the relationship between IoT and big data?

IoT and big data are two different technologies closely related to each other. Their implementation helps to achieve technological advances. While the IoT mainly helps to gather data from physical objects by means of various sensors, big data technologies allow for rapid and effective storage and processing of this data.

What is the main function of industrial IoT data management software?

The undeniable benefits provided by IIoT technologies are evident after the data produced by IoT devices reaches its final destination – an IIoT data management software system. It functions as a data hub and ensures data aggregation, processing, and transformation.

Rate this article

5/5.0

based on 1,124 reviews