Platform overview

Yalantis Predictive ML Model — based on machine learning algorithms — is customizable and easy to integrate. It’s focused on supporting businesses with quick and efficient data processing, enabling predictive analytics, and facilitating industrial equipment maintenance in various industries. Primarily, it supports energy consumption optimization, but it can easily be adjusted to meet other business needs. The model can function on its own or be integrated with larger systems already used by businesses to monitor energy consumption of industrial equipment or across premises.

Common challenges addressed by Yalantis Predictive ML Model

Based on our experience working on IoT solutions in multiple industries, we know that implementing a data-driven environment for energy consumption monitoring and management entails a multi-stage process of working with IoT data. This includes enabling different flows for gathering, pre-processing, processing, storing, analyzing, and visualizing energy consumption data — not to mention that everything should be done in real time. Decisions based on this data need to be relevant and justified. Unfortunately, this process presents businesses with the following challenges:

- A cumbersome process of gaining control over complicated energy-consuming systems

- Inability to accurately plan regular industrial equipment maintenance, updates, and remote troubleshooting to ensure consistent operation

- Suboptimal energy generation and distribution due to an inability to make data-driven decisions

- Technical incapacity to obtain crucial information about excessive energy consumption on time and localize a problem

- Absence of proper energy consumption forecasting, leading to inaccurate budget planning and allocation

- Inability to identify opportunities for demand response programs and balancing system load

- Low visibility of energy consumption in industrial patterns that prevent predictive analytics

Benefits of Yalantis Predictive ML Model

-

01

Optimized resource consumption. Yalantis Predictive ML Model aims to optimize energy consumption by analyzing real-time data from IoT devices installed across premises and equipment.

-

02

Reduced downtime and improved overall operational efficiency. By analyzing real-time data within seconds, the model can easily identify anomalies in energy consumption and promptly notify administrators. This enables timely responses to warnings and helps prevent downtime.

-

03

70% simplified data processing and analysis flow enabled by the data training model. Yalantis Predictive ML Model supports the processing of gigabytes of data from various sources, such as sensors, applications, or any other data-producing systems. The ML model for quick data analysis and anomaly recognition signals incoming issues and enables users to make data-driven decisions on the spot.

-

04

Reduced maintenance costs. Anomaly detection enabled by Yalantis Predictive ML Model allows businesses to instantly detect dangerous or abnormal equipment or system behavior. Managers and administrators can then localize and address issues before they affect other parts of the system. This results in reduced maintenance costs, as businesses only need to repair specific areas instead of the entire system.

-

05

Accurate load forecasting. Machine learning models can analyze historical data to forecast future load patterns, enabling utilities to optimize resource generation and distribution.

-

06

Advanced risk mitigation. The ML model, with the capability to process large volumes of data in minimal time, helps identify potential risks and uncertainties, significantly reducing the possibility of serious issues and discrepancies in work.

Functionality enabling and speeding up advanced operations with IoT data

Yalantis Predictive ML Model offers the following functionality:

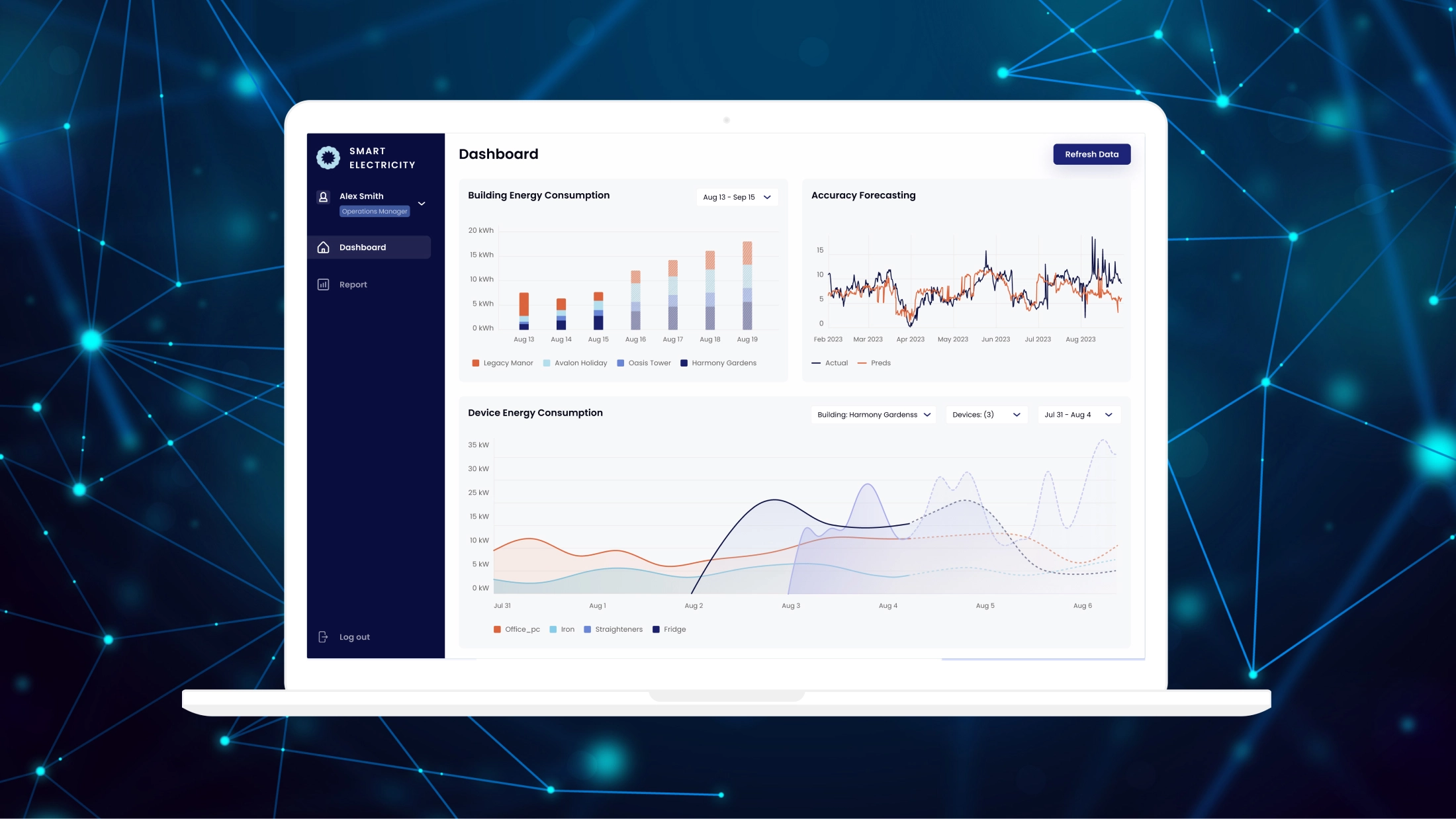

- Energy consumption forecasting. The model enables predictive maintenance in energy consumption management by processing real-time data gathered from IoT sensors. ML algorithms analyze available information, identifying trends and patterns, and generate predictions about future consumption.

- Anomaly detection. Yalantis Predictive ML Model is trained to detect energy consumption anomalies. Thus, it will detect any anomalies relative to the system’s normal operation. These may include critical incidents, such as technical glitches, or potential disruptions to equipment functionality.

- Notification center. When algorithms detect anomalous energy consumption, managers and administrators get notified about this by the system so they can make decisions regarding further equipment operation.

- Advanced data analysis and interpretation. The ML model can recognize complex patterns and correlations that might be difficult for humans to identify. In terms of data interpretation, Yalantis Predictive ML Model is able to summarize data into meaningful insights. For example, it can generate summaries or highlight key trends.

- Integration with Yalantis IoT Accelerator for sophisticated data visualization. Yalantis Predictive ML Model is designed for easy integration with Yalantis IoT Accelerator and other systems that businesses exploit. This enables comprehensive data visualization with dashboards and exhaustive reports.

Machine learning methods and algorithms

- Number of generated features for trained model: 75

- Forecast model algorithm: XRBoost

- Anomaly detection methods: Local outlier factor (LOF); Static method based on the probability of achieving an energy consumption number (0.995 percentile)

Check out this video to see how the product works:

System architecture

Use cases proving Yalantis Predictive ML Model should be an integral part of your IoT solution

-

Forecasting energy consumption and balancing supply for a selected period of time improves budget planning, budget allocation, and scheduling of equipment maintenance

-

Optimized energy consumption for improved business sustainability reduces the carbon footprint and provides a safe working environment

-

Timely identification of technical glitches helps avoid downtime and work discrepancies and enables proactive IoT maintenance to prevent future incidents with equipment and unexpected repairs

-

ML-powered anomaly detection and notification of possible incidents beforehand so they can be fixed promptly reduces maintenance costs for industrial equipment