Predictive Maintenance Services

Yalantis provides custom predictive maintenance development, building AI-powered software and IoT solutions that turn reactive maintenance into a proactive tool for reliability, efficiency, and cost savings.

Challenges Predictive Maintenance Solves

-

Unplanned downtime from sudden vehicle failures

Instead of reacting to a breakdown on the road, which causes delivery delays and expensive emergency repairs, predictive maintenance provides a forward-looking view. By analyzing sensor data, it forecasts potential component failures before they happen, allowing you to schedule service during planned off-hours.

-

Over-maintenance from rigid service schedules

Forget replacing parts based on fixed mileage or time intervals, which often leads to discarding healthy components. Predictive maintenance shifts to a condition-based approach, ensuring that service is performed only when data shows it’s actually needed, optimizing spend on both parts and labor.

-

No real-time visibility into component health

Without clear data, fleet managers are often blind to the gradual degradation of critical parts like engines, transmissions, and brakes. Intelligent monitoring transforms this ambiguity into awareness, providing a continuous health score for key vehicle systems across your entire fleet.

-

Bloated spare parts inventory due to uncertainty

Maintaining a large, costly inventory of spare parts to guard against unexpected failures ties up significant capital. By accurately forecasting when specific components will require replacement, you can move to a just-in-time parts strategy, reducing inventory costs and waste.

-

Rising fuel costs from subtle performance issues

Minor, undetected problems such as degrading fuel injectors or incorrect tire pressure can slowly increase fuel consumption across the fleet. Predictive analytics can spot these subtle performance anomalies early, flagging vehicles for tuning to restore optimal fuel efficiency.

-

Heightened safety risks from undetected mechanical problems

The risk of a catastrophic failure in safety-critical systems like brakes or tires is a constant concern for driver safety and liability. Predictive maintenance identifies stress patterns and abnormal wear, providing crucial alerts to address potential safety hazards before they lead to an incident.

Yalantis Predictive Maintenance Services

-

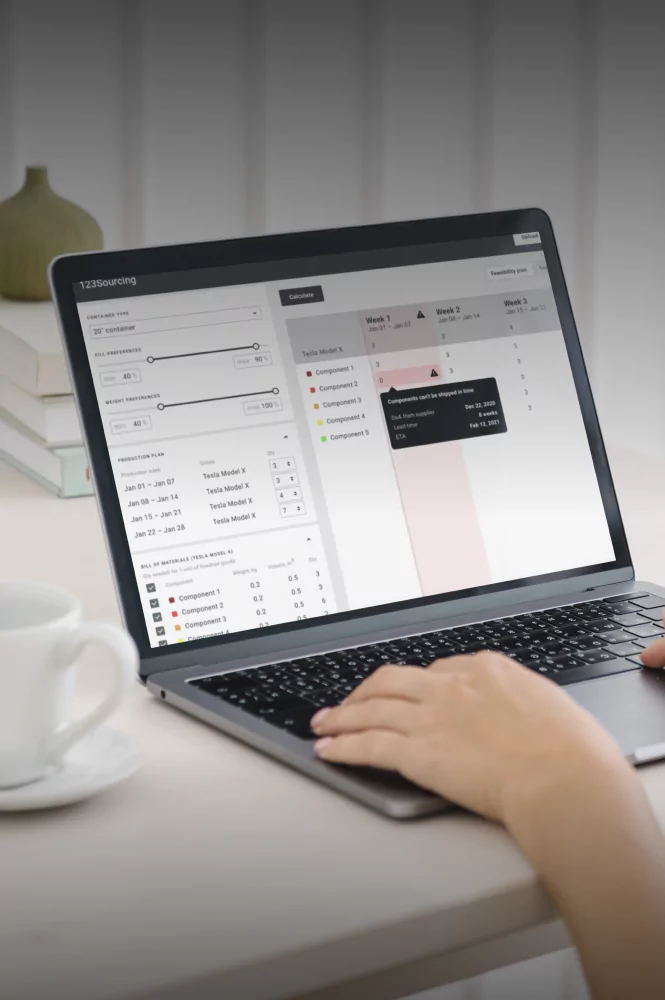

End-to-End Predictive Maintenance Platform Development

A fully managed service to design, build, and deploy a complete predictive maintenance solution, handling everything from sensor installation and data integration to providing actionable failure predictions integrated into your existing workflows.

Key Features:

- Custom Sensor & Hardware Deployment

We identify critical asset failure modes and deploy the right industrial-grade sensors (vibration, thermal, etc.) to monitor them effectively. - Multi-Source Data Integration

A robust data pipeline to collect and harmonize data from new sensors, existing telematics, PLCs, SCADA systems, and MES platforms. - Anomaly Detection

AI models learn the unique operational “heartbeat” of each asset, detecting subtle deviations from the baseline that indicate a potential issue. - Failure Prediction & RUL Estimation

Advanced models classify anomaly patterns to predict the specific type of failure and estimate the Remaining Useful Life (RUL) of a component. - Custom Model Development

A dedicated data science team to build and train machine learning models tailored specifically to your machinery and operational context. - Asset Health Command Center

A secure cloud platform providing a single source of truth for asset health, with dynamic health scores that show what needs immediate attention. - Actionable Failure & Anomaly Alerts

High-confidence alerts are generated with specific details, such as “Bearing failure on Conveyor B predicted in 7-10 days,” for proactive planning. - CMMS & ERP Workflow Integration

Seamless integration that automatically creates prioritized work orders in your CMMS (e.g., SAP PM, Maximo) and checks spare parts inventory in your ERP.

- Custom Sensor & Hardware Deployment

-

AI/ML Predictive Model Development

A dedicated data science service for clients who have already collected asset data but lack the in-house AI expertise to build, train, and validate custom predictive models that can accurately forecast equipment failures.

Key Service Deliverables:

- Data Exploration & Feature Engineering

We analyze your raw sensor and operational data to identify the key signals and variables that are most predictive of asset failures. - Custom Predictive Model Training

Our data scientists use your historical data to build and train machine learning models specifically tailored to your unique assets and environment. - Model Validation & Performance Tuning

Rigorous back-testing and validation processes ensure the models are accurate and reliable, tuned to minimize false positives and negatives. - Model Deployment & API Integration

We package the finished model and deploy it with a simple API, allowing your existing applications and workflows to get real-time predictions. - Ongoing Model Monitoring & Retraining

Continuous monitoring of model performance in a live environment, with periodic retraining to adapt to changing asset conditions or new failure modes.

- Data Exploration & Feature Engineering

-

IoT Sensor Strategy & Deployment

A consultative engineering service that solves the challenge of data acquisition. We analyze your critical assets, identify the most effective sensor types, and manage the full hardware deployment to start collecting high-quality data without disrupting operations.

Key Service Deliverables:

- Asset Failure Mode Analysis

Our engineers work with your team to identify the most critical failure points and determine the best data to capture for accurate prediction. - Sensor & Hardware Selection

We provide expert, vendor-agnostic recommendations for the most reliable and cost-effective sensors (vibration, thermal, etc.) for the job. - On-Site Installation & Commissioning

A managed, end-to-end installation process planned to minimize operational disruption and ensure hardware is correctly installed and calibrated. - Data Connectivity & Gateway Setup

We configure industrial gateways and wireless networks to ensure sensor data is transmitted reliably and securely from the factory floor to the cloud. - Data Quality & Integrity Validation

Post-installation, we verify that the sensors are capturing clean, consistent, and accurate data streams that are ready for advanced analysis.

- Asset Failure Mode Analysis

-

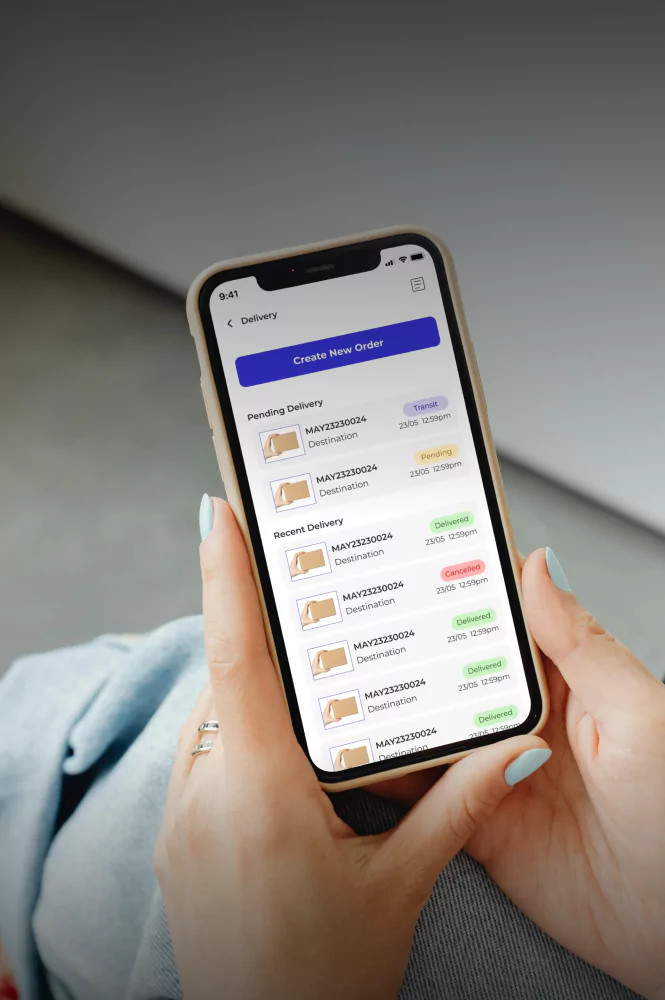

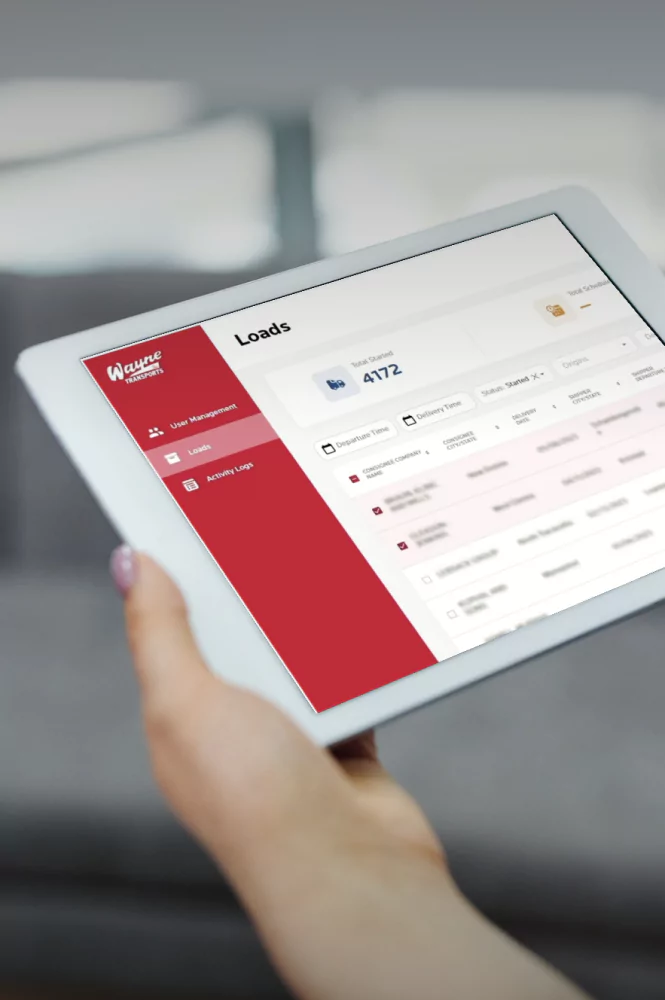

Data Integration & Pipeline Development

A specialized data engineering service designed to solve the problem of siloed information. We build robust data pipelines to collect and harmonize data from your PLCs, sensors, telematics, and CMMS into a single, analysis-ready location for your teams to use.

Key Service Deliverables:

- Multi-Source Connector Development

We build custom connectors to pull data from your disparate systems, including industrial PLCs, SCADA, ERPs, and proprietary databases. - Data Ingestion & Transformation

Development of robust ETL (Extract, Transform, Load) processes to move massive volumes of data and convert it into a standardized format for analysis. - Centralized Data Storage Setup

We architect and implement a unified data lake or warehouse, creating a single source of truth for all your historical and real-time operational data. - Data Cleansing & Harmonization

Custom scripts and processes to clean, de-duplicate, and structure messy or inconsistent data, making it reliable for analytics and AI models. - Pipeline Monitoring & Maintenance

We provide tools and services to monitor data pipeline health, ensuring data flows consistently and reliably without interruption or loss.

- Multi-Source Connector Development

-

Standalone Root Cause Analysis (RCA) Module

A software module that integrates with your existing alert systems. It upgrades basic alarms with advanced visualization and diagnostic tools, helping technicians spend less time guessing and more time rapidly determining the true root cause of a failure.

Key Service Deliverables:

- Interactive Data Visualization

Tools that allow engineers to drill down into specific sensor readings, overlay multiple data streams, and explore historical performance trends. - CMMS & Alert System Integration

Pre-built connectors that link the module with your existing maintenance and alert platforms, enriching basic alarms with deep diagnostic data. - Historical & Real-Time Data Correlation

The ability to compare a live anomaly against historical failure data and maintenance logs to quickly identify recurring patterns and likely causes. - AI-Assisted Diagnostics

A feature that analyzes the unique data signature of a failure and suggests the most probable root causes for technicians to investigate first. - Collaborative Reporting Tools

Functionality to easily capture findings, annotate data charts, and generate diagnostic reports to share with the wider maintenance and engineering teams.

- Interactive Data Visualization

Predictive Maintenance Solutions for different industries

Case studies

Benefits of developing a predictive maintenance solution with Yalantis

-

Maximize Operational Uptime

Our expertise in asset failure modes and custom AI models allows us to forecast component failures, transforming costly unplanned downtime into scheduled, low-disruption service events.

-

Optimize Maintenance Spend

Our full-stack solution transitions you from rigid, calendar-based service to condition-based maintenance, ensuring you only spend on parts and labor when data shows it’s necessary.

-

Maximize Asset Value & Lifespan

We build systems that provide deep visibility into component health, allowing you to address minor issues proactively and extend the operational life of your most high-value assets.

-

Enhance Operational Safety

Our experience allows us to identify stress patterns in safety-critical systems, providing crucial early warnings to your team to mitigate mechanical risks before they lead to an incident.

-

Streamline Spare Parts Inventory

By accurately forecasting component failures, our solutions let you move from a capital-intensive “just-in-case” inventory to a lean, cost-effective “just-in-time” model.

-

Unlock Actionable Asset Intelligence

We balance advanced AI with practical strategy to transform raw sensor readings into clear, actionable insights, empowering your team to make smarter, data-driven maintenance decisions.

Technologies we work with

-

Rust

-

C

-

C++

-

Kotlin

-

Bootloader

-

Linux Kernel

-

AWS IoT

-

Arduino

-

ESP32

-

STM32

-

NRF52

-

Zephyr

-

LoRaWAN

-

MQTT

Compliance and security support

Security for your supply chain

-

ISO 28000

-

DTLF

-

CISA / NIST

RFID-powered Logistics

-

GS1 EPC/RFID

-

ISO 17363–17365

Testimonials from our clients

Predictive Maintenance ServicesInsights

How Can IoT for Predictive Maintenance in Logistics Transform Your Fleet Operations

Learn how IoT sensors and Rust-powered systems enable predictive maintenance in logistics. Reduce downtime and boost reliability.

How Manufacturers Use IoT for Predictive Maintenance

Learn about the benefits of Internet of Things predictive maintenance for large manufacturers and how a web application can increase its effectiveness.

Being informed in advance: IoT predictive maintenance

Discover how IoT predictive maintenance can enhance equipment performance and reduce downtime. Read the essential guide to optimize your operations now.

FAQ

How is predictive maintenance different from the preventive maintenance we already do?

While preventive maintenance is a valuable step, it operates on fixed schedules (time or mileage), often leading to unnecessary service and part replacements on healthy assets. Predictive Maintenance (PdM) is far more intelligent. It uses real-time data from IoT sensors and machine learning to monitor the actual condition of your equipment. Instead of servicing on a schedule, you perform maintenance precisely when it’s needed, just before a potential failure occurs. This data-driven approach maximizes asset lifespan, reduces costs, and drastically improves operational uptime.

What is the process for implementing a predictive maintenance solution with your team?

The process begins with a deep discovery and assessment phase where we work to understand your specific challenges, key assets, and business goals. From there, we devise a comprehensive data and hardware strategy, leveraging any existing data sources and deploying custom IoT sensors where needed. Our data scientists then develop custom machine learning models while our engineers build the software platform to deliver alerts and insights. The final stages involve integrating the platform into your existing workflows, rolling it out to your team with full training, and providing ongoing support to ensure the solution continuously delivers maximum value.

What kind of data and equipment do we need to get started?

This is a common question, and the answer depends on your current setup. Many modern fleets and facilities already have equipment with built-in sensors and telematics systems that generate valuable data. Our first step is always to assess if we can leverage your existing data. If there are gaps, our team specializes in end-to-end IoT development, meaning we can design, build, and install the specific sensors and data pipelines required to monitor your critical assets effectively.

How long does it take to see a return on investment (ROI)?

While the full implementation timeline varies based on complexity, initial insights can often be generated within the first few months. The ROI for predictive maintenance is significant and multifaceted, coming from direct cost savings across your operation. You will see returns from the reduction in unplanned downtime, lower overall maintenance costs by eliminating unnecessary service, and the ability to run a leaner, just-in-time parts inventory. Furthermore, by ensuring your equipment runs under optimal conditions, you protect your long-term capital investment by extending its operational life.

How does a Predictive Maintenance platform integrate with an existing CMMS or ERP system?

Seamless integration with your existing systems is not just a feature; it is fundamental to operationalizing insights and maximizing value. A modern PdM platform acts as an intelligent layer that complements your Computerized Maintenance Management System (CMMS) or Enterprise Resource Planning (ERP) software. The process is a two-way street facilitated by robust APIs. Initially, the PdM platform ingests historical maintenance records and work order data from your CMMS/ERP to enrich and accelerate the training of its machine learning models.

Once operational, the real power becomes evident: when the PdM platform predicts an impending asset failure, it automatically triggers an action in your existing system. This could be generating a detailed work order in your CMMS, checking spare parts availability in your ERP’s inventory module, and even scheduling the required maintenance technician. This creates a closed-loop workflow that transforms a data-driven prediction into a concrete, scheduled action without manual intervention, turning your CMMS from a simple record-keeping tool into a proactive, intelligent system.

Can a Predictive Maintenance program be scaled from a pilot project to a full enterprise deployment?

Yes, not only is this possible, it is the most effective and recommended strategy for enterprise adoption. A successful deployment begins with a strategic pilot program focused on a small number of high-value, critical assets that have well-understood failure modes. This allows us to quickly demonstrate tangible ROI, refine the machine learning models on a manageable dataset, and establish a clear business case for expansion. The key is to prove value early and create internal champions for the program.

Once the pilot is successful, we leverage a scalable cloud architecture and the established data models to create a standardized blueprint for a phased, enterprise-wide rollout. This methodical approach allows your organization to manage change effectively, learn from each phase, and expand the program’s footprint across different facilities or asset classes with confidence. This ensures that the solution grows with your operational needs and delivers compounding value as more assets are brought online.

How do your custom machine learning models minimize false positives and alert fatigue?

Alert fatigue is a primary reason why generic PdM initiatives fail; if technicians are constantly chasing phantom issues, they will lose trust in the system. We combat this directly through the development of highly specific, custom machine learning models. Unlike off-the-shelf software that uses generic algorithms, our models are trained exclusively on your historical data, allowing them to learn the unique operational “fingerprint” of each of your assets. They understand that a pressure spike which is normal during a startup sequence is a critical anomaly during steady-state operation.

Furthermore, we utilize sophisticated feature engineering to isolate the most predictive data signals while ignoring system noise. Most importantly, our platforms include a human-in-the-loop feedback mechanism. This allows your expert technicians to validate alerts, confirming whether a prediction was accurate. This feedback is then used to continuously retrain and refine the models, creating a system that gets smarter and more accurate over time, ensuring that when an alert is triggered, it warrants immediate attention.

What is the difference between Predictive and Prescriptive Maintenance, and is that a future capability?

This is an excellent question that gets to the future of industrial maintenance. Think of it as an evolution in intelligence. Predictive Maintenance excels at answering the questions, “What will likely fail?” and “When will it likely fail?” It provides a forecast, a probability, and a time window, enabling you to plan and schedule maintenance proactively. For example: “Alert: Bearing B-123 on Conveyor 4 shows a 75% probability of failure in the next 150 operating hours.”

Prescriptive Maintenance is the next logical step, answering the crucial follow-up question: “What should I do about it?” It analyzes the prediction in the context of broader operational data and provides a specific recommendation. The same alert in a prescriptive system might read: “Alert: Bearing B-123 will likely fail. We recommend replacing it during the scheduled plant-wide downtime on Tuesday. The required part (PN-X) is in stock at the primary warehouse. Click here to automatically generate a work order and allocate the part.” The robust data infrastructure and accurate models we build for your predictive solution are the essential foundation required to unlock prescriptive capabilities in the future.

Contact us

got it!

Keep an eye on your inbox. We’ll be in touch shortly

Meanwhile, you can explore our hottest case studies and read

client feedback on Clutch.

Nick Orlov

IoT advisor

How to get started with IoT development

-

Get on a call with our Internet of Things product design experts.

-

Tell us about your current challenges and ideas.

-

We’ll prepare a detailed estimate and a business offer.

-

If everything works for you, we start achieving your goals!