AI consulting services

Get a comprehensive, objective overview of your organization’s AI readiness and prepare

for the AI journey with a detailed implementation action plan. Identify and leverage the highest-ROI AI use cases that will help you secure a strategic competitor advantage.

AI consulting services Yalantis provides

-

Data strategy and architecture evaluation

- Assessing existing data strategy, infrastructure, and architecture for AI readiness

- Evaluating data quality and data management practices

- Identifying gaps in data management

- Preparing an AI adoption roadmap with optimal business value

- Outlining recommendations on closing gaps in data collection, storage, and governance

-

AI implementation roadmapping

- Assessing current data capabilities and needs

- Identifying the artificial intelligence use cases with the highest business value

- Developing or evaluating an AI strategy based on the identified business goals

- Selecting the best use case for a pilot project/proof of concept

- Preparing a detailed roadmap for implementing AI solutions for the selected use cases

-

AI/ML solution feasibility study

- Assessing business requirements and existing infrastructure

- Identifying the resources required for AI implementation

- Comparing resource requirements against available resources

- Evaluating the viability and potential benefits of AI/ML projects

- Calculating the expected ROI for your AI project

-

AI solution design and development

- Translating business needs into technical and non-technical requirements

- Conducting buy vs build analysis

- Identifying the best-suited off-the-shelf AI solutions based on use cases and needs

- Integrating and customizing off-the-shelf AI technologies

- Selecting the appropriate technology stack for custom AI solutions

- Building, validating, and implementing AI solutions

-

ML-powered module development

- Identifying the most suitable machine learning algorithms

- Assessing available data sources for training ML models

- Gathering and cleaning data for ML development

- Building, training, validating, and integrating custom ML models

AI/ML solutions Yalantis specializes in

-

AI-driven forecasting

Predict customer behavior, supply and demand, and market conditions with predictive analytics powered by supervised, unsupervised, or autoregressive machine learning models. Ensure predictive insights’ reliability and accuracy with AI technology consulting and data quality assessments.

-

AI content analysis

Harness the value of unstructured data with AI-powered computer vision, natural language processing, sentiment analysis, data classification, and more. Identify the highest-ROI data sources and their use cases with expertise-driven AI consulting services.

-

Portfolio optimization

Resolve the combinatorial optimization problem with self-improving algorithms optimized for high performance. Identify the right approach for overcoming optimization challenges, from simulated annealing to reinforcement learning agents.

-

Customer segmentation

Gain a unified view of your customer data and define the most valuable analytics use cases with our AI consultancy. Leverage predictive analytics for targeted marketing and new feature deployment based on customer behavior and trend forecasting.

-

Fraud detection

Minimize the risk of undetected fraud with ML-powered fraud detection and prevention systems. Address the most pressing issues like transaction fraud, identity theft, and account takeover with the right AI-powered solution identified by our AI consulting team.

-

Data mining

Select the right data mining technique (e.g., association/regression analysis) to power smarter decision-making and improve data analytics reliability and accuracy. Unify your data in a single source of truth with guidance from our artificial intelligence consultants.

Yalantis: Your AI consulting company with a proven track record

Technologies we work with

-

TensorFlow

-

PyTorch

-

Scikit-learn

-

AWS SageMaker

-

Google Vertex AI

-

Hugging Face Transformers

-

Apache Airflow

-

MLflow

-

AWS Glue

-

Flyte

Industry-specific AI consulting use cases we work with

Our clients’ reviews

Our approach to powering AI with relevant, well-structured data

-

Discovery

Our AI consultants start by defining the key business problems your enterprise seeks to resolve with AI. We invest time in understanding your business processes and pain points to identify specific, attainable business objectives.

-

Feasibility assessment

We estimate the potential ROI and analyze the requirements against the available technologies to establish the project’s feasibility. Our AI consulting firm also prepares detailed estimates for the resources required and identifies the appropriate technology stack.

-

Data collection, discovery, and profiling

Our artificial intelligence consultants identify and collect relevant structured and unstructured historical data in a single source of truth, such as a data warehouse or data lake. We then explore the data and assess its quality and limitations.

-

Data cleansing, analysis, and structuring

We clean and preprocess data to ensure its quality, integrity, and reliability for future use in AI models. Our experts also structure and standardize data to improve its usability if necessary.

-

Data validation

As a data and AI consulting company, we verify data accuracy and reliability with rigorous validation against pre-defined quality criteria, ground truth, or known outcomes.

-

Development, training, and fine-tuning

Per your request, we can take on AI development and training using the prepared first- and third-party datasets. We fine-tune the model to ensure its reliability, accuracy, and performance in the long run.

-

Integration and support

We can also integrate AI solutions within your infrastructure and integrate them with your digital ecosystem. Our AI services cover performance monitoring and maintenance, as well.

Results our artificial intelligence consulting services can deliver

-

Increased employee productivity

Track and improve employee performance, remove time wasters with intelligent automation, and optimize task allocation to enhance productivity and reduce labor costs.

-

More effective problem-solving

Easily identify root causes of business disruptions, operational inefficiencies, or negative customer feedback with AI solutions that easily handle multidimensional issues and predictions.

-

Improved cybersecurity

Protect your sensitive data and software systems with accelerated security risk discovery, effective cyber threat prevention, and automated incident response.

-

New revenue streams

Adopt a new business model or leverage a new monetization opportunity with artificial intelligence consulting services that identify the most lucrative revenue streams.

-

Enhanced customer experiences

Bridge the gap between your services and your customers’ needs and expectations with personalization at scale, AI-augmented customer support, and 360-degree customer analytics.

-

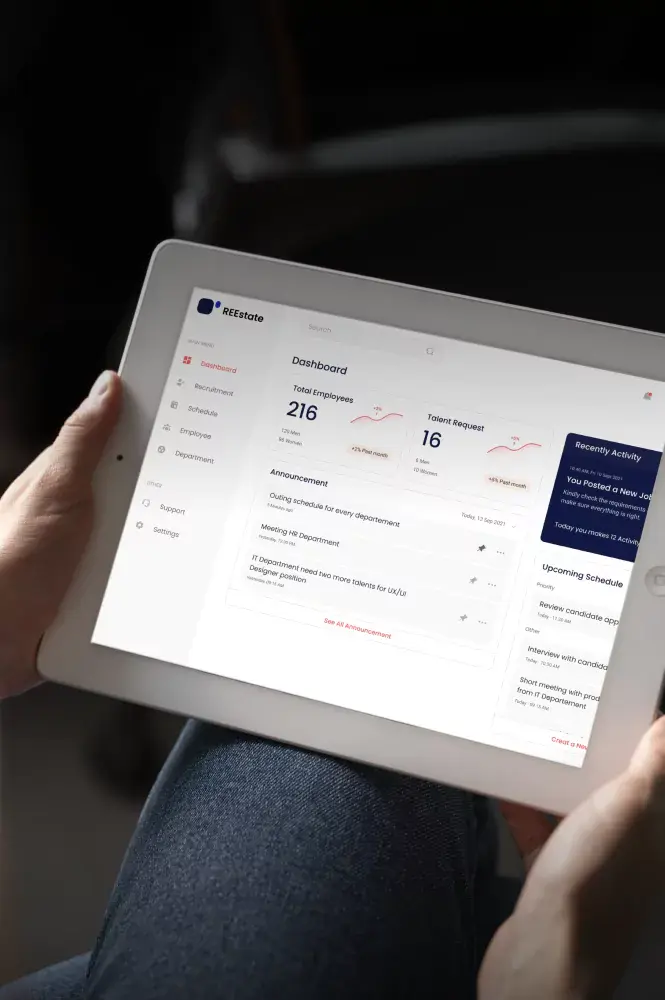

Facilitated recruitment

Reduce recruitment costs while ensuring the best fit for every job with AI-powered candidate screening and analysis, onboarding, and equitable pay calculation.

Benefits of partnering up with Yalantis

Improved ROI

Identify the most profitable business opportunities for AI innovation and select the most cost-efficient and best-suited technologies with a feasibility study.

Effective AI adoption

Streamline implementation and minimize the risk of resource waste with a detailed AI transformation roadmap for your use cases from an experienced AI consulting agency.

Faster results

De-risk AI development and deployment and maximize its ROI with an implementation strategy tailored to your desired business outcomes and current data landscape.

Mitigated risks

Prevent biased output, minimize compliance risks, and ensure model security and accuracy with AI strategy consulting that includes risk assessment and mitigation.

Facilitated collaboration and problem-solving

Democratize access to data insights across the organization to foster a data-driven culture, promote informed risk-taking, and enable continuous process improvement.

Alignment with your unique needs

Customize off-the-shelf BI tools, set up a tailored data collection and processing pipeline, and implement custom data integrations with third-party and legacy systems.

Useful insights

Predicting house price using regression algorithm for machine learning

We have prepared a step-by-step guide of using regression algorithms in machine learning, to help you predict house prices for a given area.

BI and advanced analytics solutions for supply chain data analysis

Read a guide on BI and advanced analytics solutions for the supply chain. Learn how to implement each one and read about common tools and techniques for both.

5 indicators your warehouse management system needs improvement

Learn why your WMS might need improvement and get practical tips on how to upgrade your software in a way that’ll bring value to your business.

FAQ

What can I expect from AI consulting with Yalantis?

Our expert team will discuss your expectations from our services at the very beginning of our collaboration. Based on those expectations, as defined by your business needs and objectives, we can evaluate your AI strategy and data infrastructure, assess AI readiness, draw up an AI implementation roadmap, conduct a feasibility study, help you select the right AI technologies, and guide you along the whole AI implementation process.

How will you evaluate the AI readiness of my organization?

Our AI readiness assessment involves evaluating your current data infrastructure (sources, types, pipelines, standardization, etc.) and its alignment with business priorities and objectives. We also analyze your data governance framework, data management strategy, and security and privacy measures across the organization. We then identify gaps in data management and suggest ways to close them.

What industries benefit the most from AI consulting?

In general, organizations in industries like healthcare, finance and banking, retail, and manufacturing stand to benefit the most from our AI services. Such organizations can significantly reduce costs with AI-powered automation and insights and have complex, expansive data infrastructures. Organizations with numerous legacy systems can also benefit from AI consulting.

Can you help us define the ROI of implementing AI?

Of course. We can estimate the required resources, financial and otherwise, for AI projects based on your specific use cases and prepare a detailed breakdown of the expected investment. Our experts then assess the ROI based on the potential productivity, efficiency, and revenue gains and expected cost savings. Our assessment will help you build your business case and secure stakeholder buy-in.

Do you provide PoC development as part of your consulting?

Yes. Per your request, we can develop a small experimental artificial intelligence solution that promptly demonstrates the value the technology can deliver to your business. Our AI development expertise includes analytics tools, chatbots, and generative AI systems. If you haven’t identified the use case for your pilot project, we can help you select the right one to secure a quick win for your business case.

What AI technologies and frameworks do you specialize in?

Our AI expertise spans natural language processing, generative AI, ML analytics (including predictive analytics), conversational AI, deep learning, sentiment analysis, speech recognition, and computer vision. As for frameworks, we work with Amazon QuickSight, Apache Spark, TensorFlow, PyTorch, Amazon Redshift, Snowflake, and more.

If you consider using a specific AI technology, don’t hesitate to reach out to us to discuss our experience with it.

How do you handle AI bias and model transparency?

We identify potential bias risks in AI integration and use based on the algorithms used and the representativeness of training datasets. Our consulting process involves preparing a detailed breakdown of those risks, along with specific measures to mitigate them. As for model transparency, we can assess the current model’s explainability, governance, and accountability.

Can you guide us through AI-related compliance requirements?

Of course. We’ll identify the applicable regulatory requirements based on your jurisdiction, company size, industry, and data types involved, as well as relevant internal policy requirements. This includes requirements for responsible AI use in decision-making, data security, and data privacy. Based on the identified requirements and our assessment of your current data practices, we’ll provide a roadmap for ensuring compliance during AI implementation.

Contact us

got it!

Keep an eye on your inbox. We’ll be in touch shortly

Meanwhile, you can explore our hottest case studies and read

client feedback on Clutch.

Lisa Panchenko

Senior Engagement Manager

Your steps with Yalantis

-

Schedule a call

-

We collect your requirements

-

We offer a solution

-

We succeed together!