As a results-focused executive, you’re always looking for ways to improve efficiency and drive profitability in your business. But implementing changes in a live environment—whether it’s a new workflow, layout, or system change—can be risky. It could use up resources, interrupt everyday work, and, in the end, may not even bring expected results.

Digital twin solutions can help by letting you:

- run scenarios in a risk-free, virtual space

- spot and solve potential issues in advance

- test improvements before applying them live

All without impacting the real-world operations you rely on.

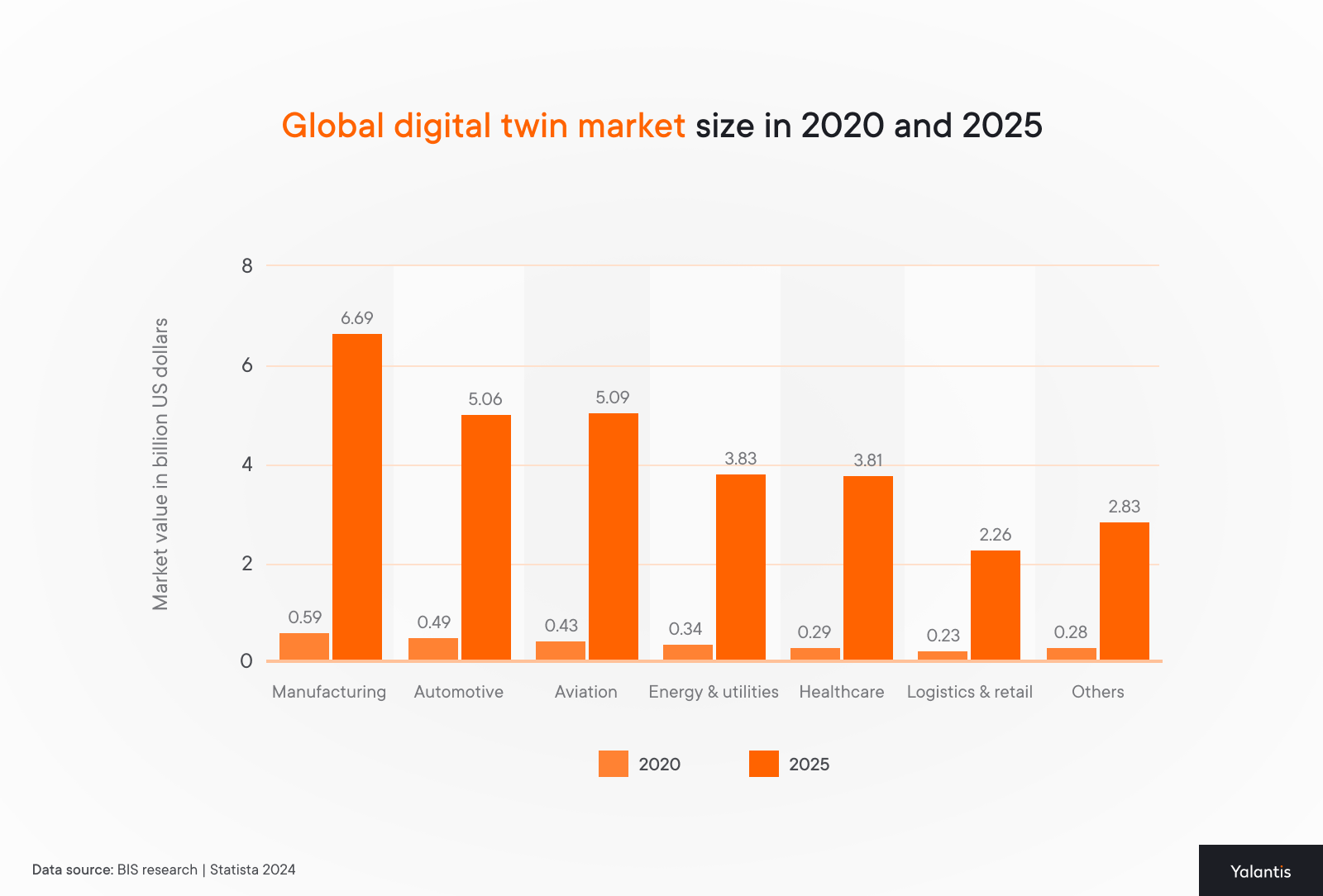

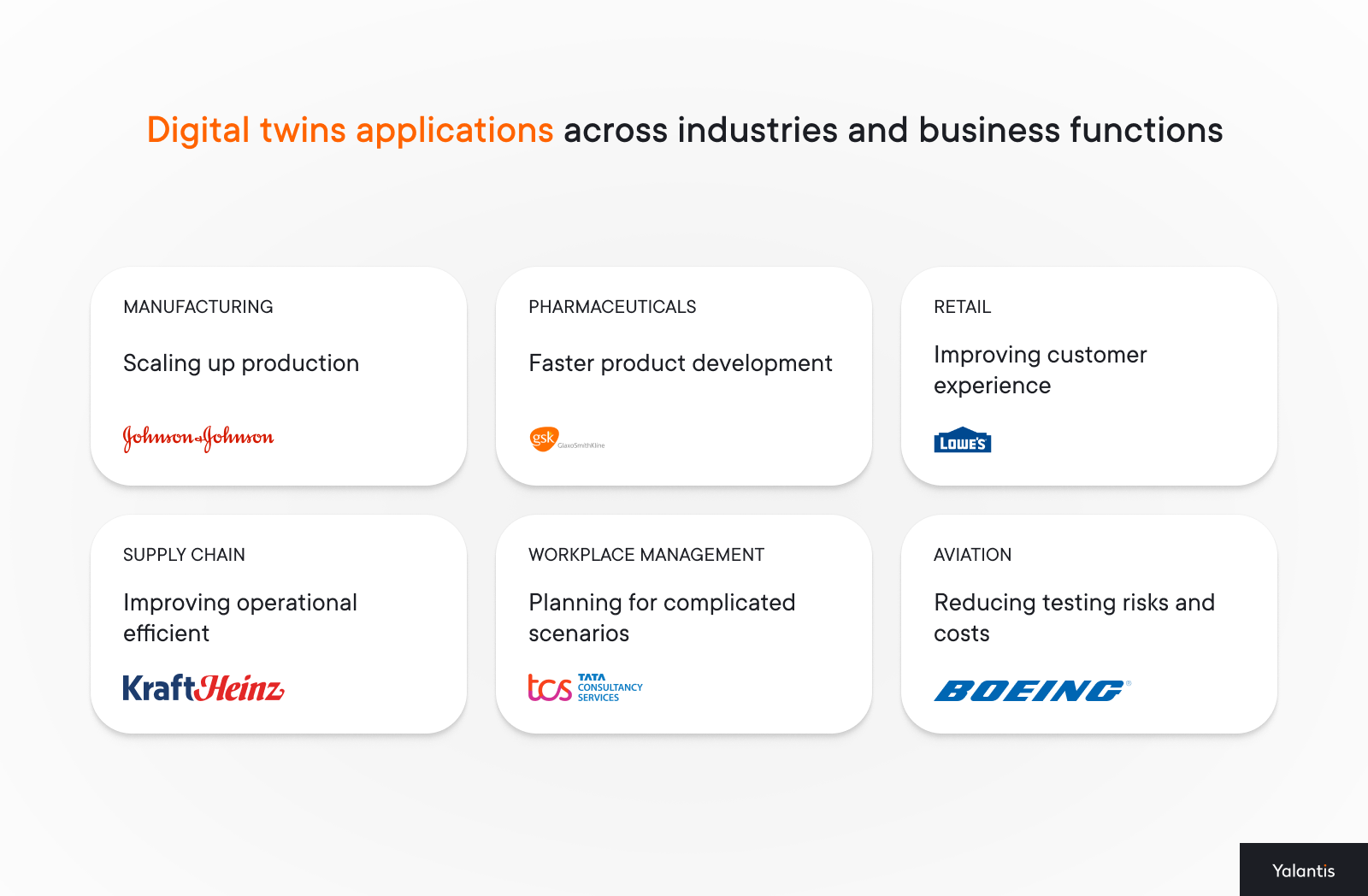

Adopting digital twins is now a popular practice across industries, from manufacturing to retail:

Why are businesses investing more in this technology? Because it helps solve key business problems, from scaling up production to enhancing customer experiences.

Read on to see real-world examples of how companies use digital twins to solve core challenges—and explore if this solution is right for your business.

A digital twin solution in action: An example from retail

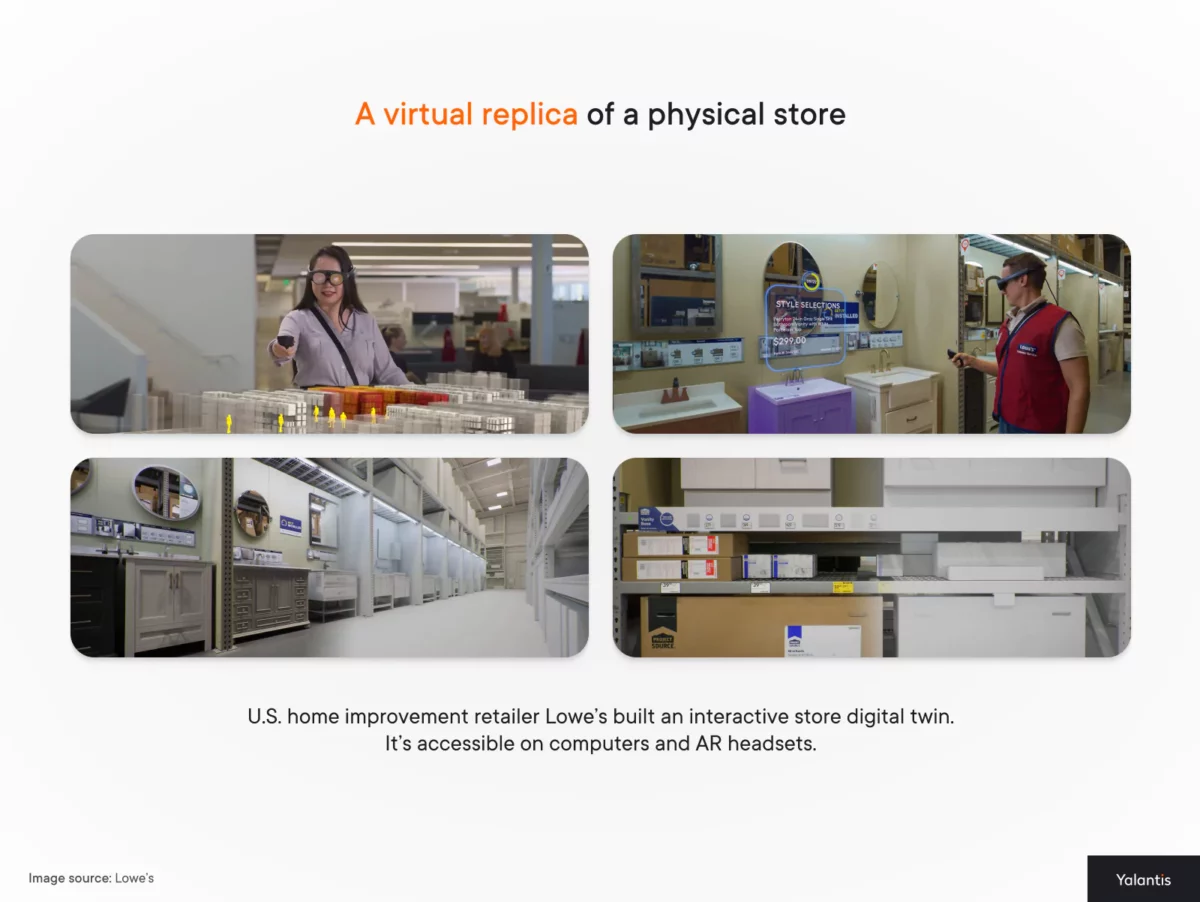

In 2022, U.S. home improvement retailer Lowe’s introduced the industry’s first interactive store digital twin. Lowe’s staff can now access real-time data—including product locations, sales history, and customer behavior—through a single, visual tool available on computers and AR headsets:

Lowe’s can quickly optimize store layouts, making it easier for customers to find products and enhancing their shopping experience.

Mason Sheffield, senior director of creative technology at Lowe’s Innovation Labs, explains that digital twins allow Lowe’s to run thousands of layout simulations overnight. They can analyze customer behaviors like shopper movement patterns and product pairings.

Intriguing, right? We’ll explain how digital twin technology works in a moment.

In the meantime, if you’re already wondering how digital twins could benefit your business, our team at Yalantis collects valuable insights on how businesses are using the latest tech to solve real-world challenges. We stay ahead by attending major retail, IoT business solutions, and other industry and technology conferences and are here to share that knowledge.

Inside the world of digital twins: How they work and improve operations

A digital twin mirrors a physical object, and it allows businesses to test and improve operations in a virtual space. This approach reduces the risks and costs of making real-world changes by first testing them digitally. Here’s a look at how digital twins work, what they look like in action, and the key technologies that power them.

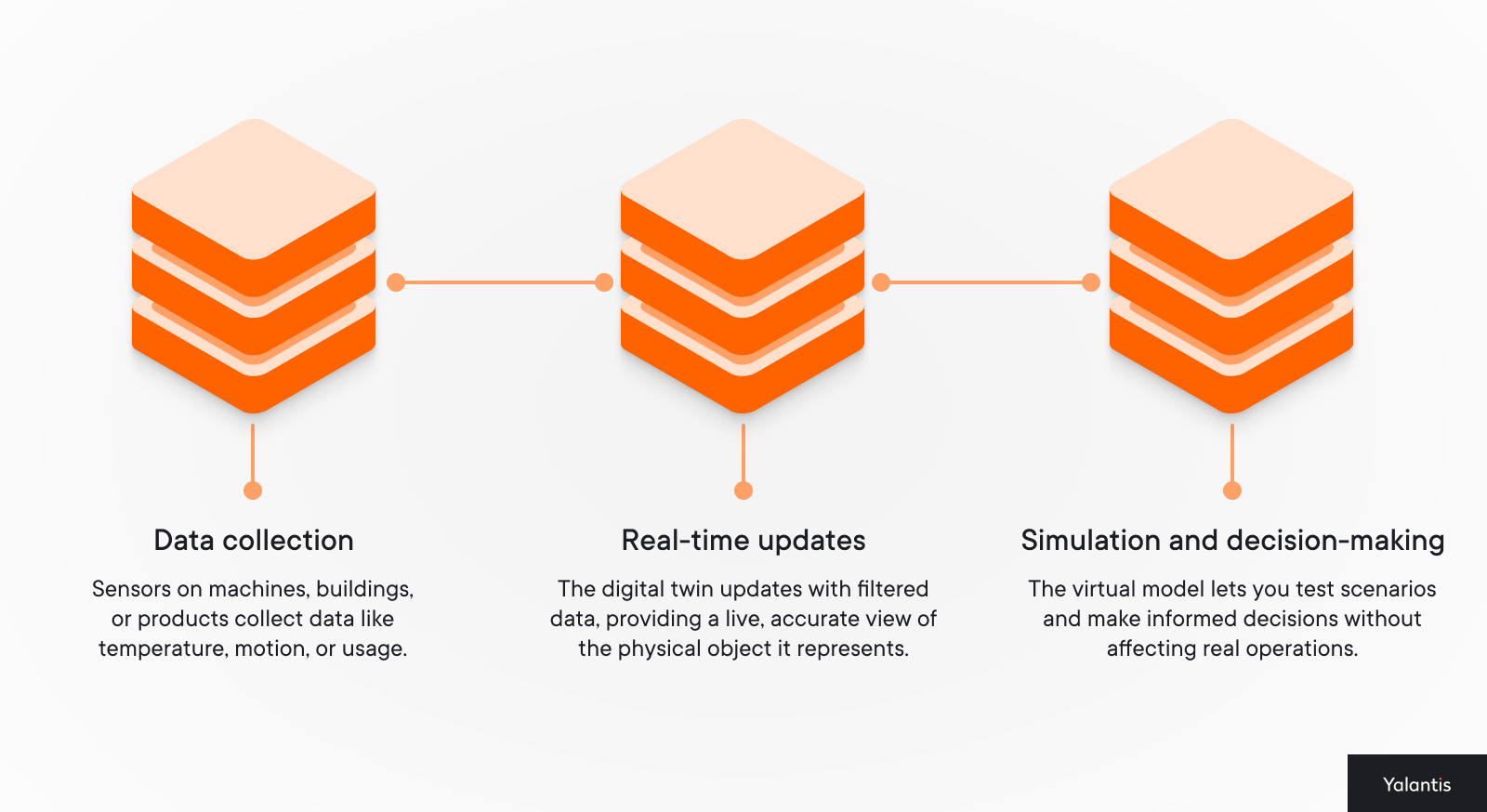

A digital twin is a digital model of a physical object or system. It receives real data from physical objects—like machines, buildings, or warehouses—to let businesses test, adjust, and improve their operations virtually. Here’s the breakdown:

Example application of a digital twin: A distribution center

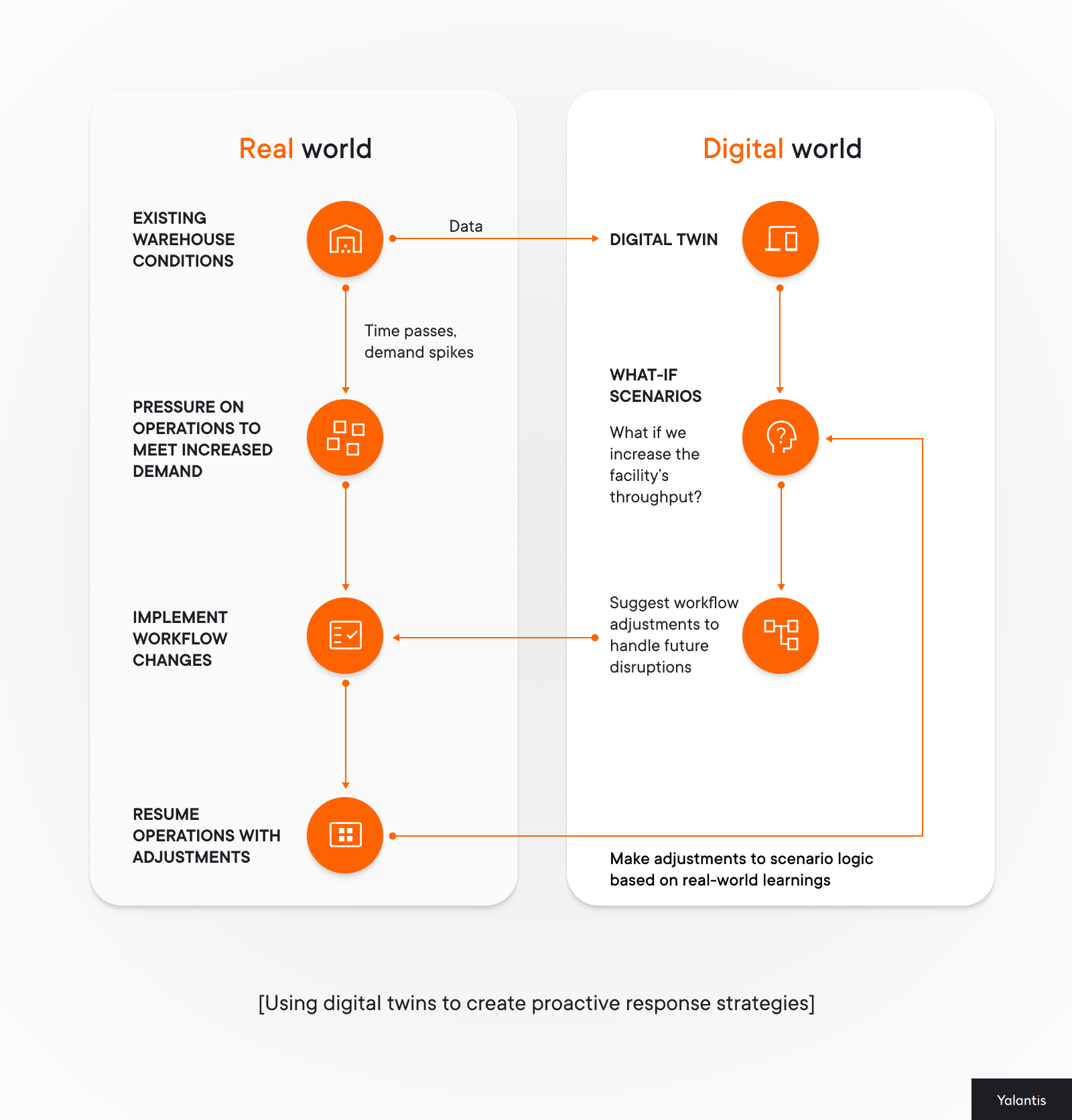

Imagine a large distribution center, like an Amazon warehouse. This facility is filled with robotics, sensors, and conveyor systems that keep parcels moving.

In this setting, a digital twin would serve as a virtual model of the entire facility’s operations. It helps operators visualize and adjust workflows without interrupting live activities.

In the physical warehouse, unexpected events, such as a surge in demand or a conveyor malfunction, can create bottlenecks or delays. The digital twin lets businesses simulate these scenarios in advance by running “what-if” analyses. Operators can see how the system would respond under different conditions and refine contingency plans. So, when a demand spike does happen, the business is prepared to act efficiently, based on the insights gathered from these simulations.

That said, the digital twin provides valuable insights that operators can act on—safely. As our expert, Mykhailo Maidan, explains:

To make this happen, digital twins use a combination of technologies. Internet of things (IoT) sensors on physical objects gathering data like temperature and movement to send it to the digital twin in real-time. Edge computing processes this data locally for quick responses, while the cloud provides remote access. Artificial intelligence (AI) and machine learning analyze the data to predict issues and optimize operations, and visualization tools, like dashboards or 3D models, present the operational data clearly, helping teams make fast, informed decisions.

Together, these technologies create a dynamic, interactive digital twin that offers deep insights into the physical world.

What does this mean for your business? Take a closer look at the benefits.

Business benefits of digital twins and the industries they transform

Digital twins empower businesses to make smarter, faster, and safer decisions through applications like:

👉 predictive maintenance that uses real-time data to spot patterns, helping prevent costly equipment issues and scheduling maintenance only when necessary—drawing on advanced IoT software development company for seamless implementation.

👉 risk-free testing that makes virtual experimentation possible, letting businesses simulate scenarios like new workflows.

👉 product lifecycle management that helps identify potential issues, optimize features, and improve durability of new products—without the need for a physical prototype. In early stages, companies can create digital twins based on prototype designs and initial data (e.g., design specifications and data from similar products or previous versions).

Explore key benefits of digital twins below:

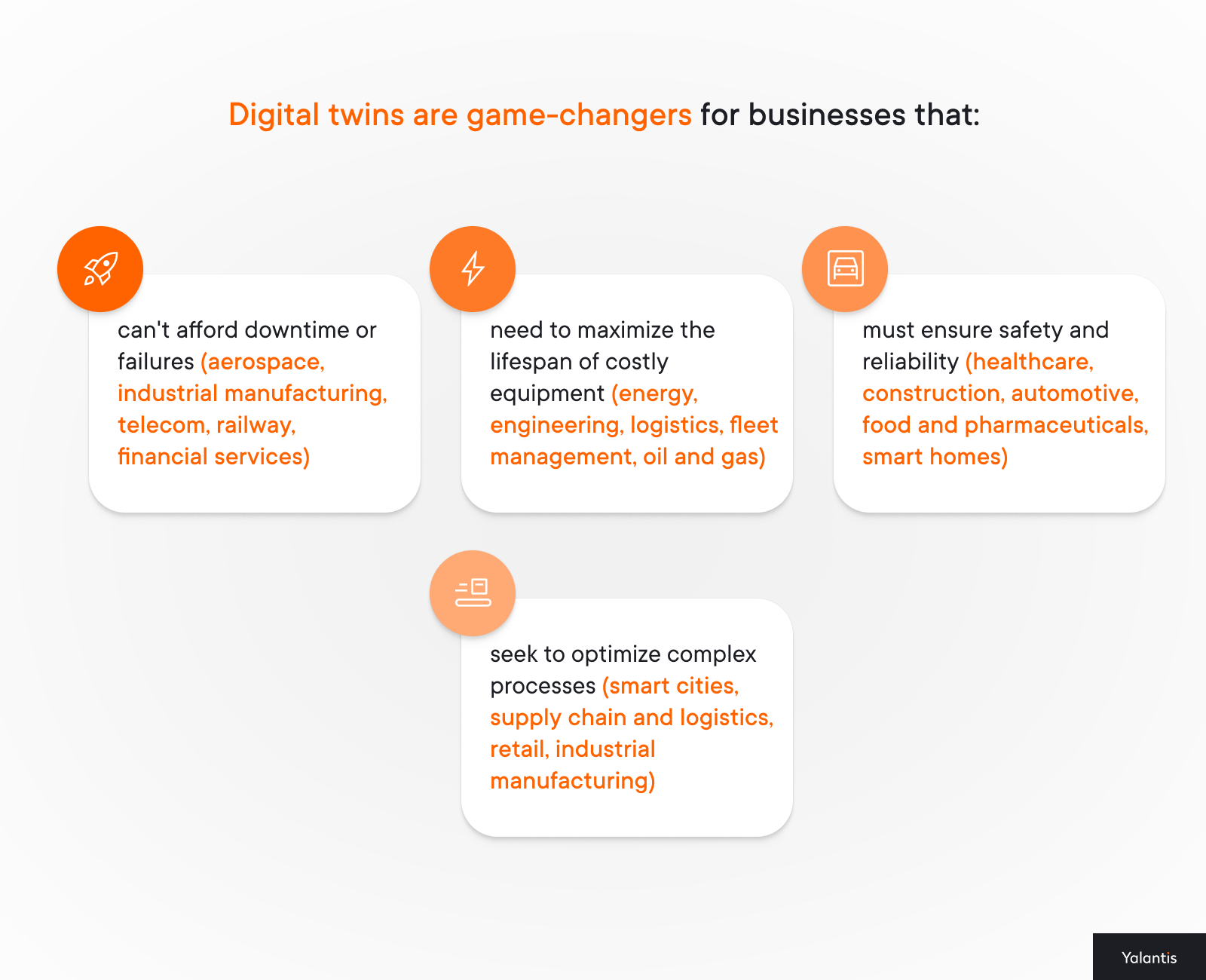

These benefits are particularly powerful for businesses in industries where:

- constant monitoring is crucial

- assets are expensive and complicated

- predicting problems before they happen is vital

As such, key industry applications of digital twins are as follows.

Industries such as engineering, manufacturing, healthcare, smart home, and logistics benefit most from digital twin solutions. These fields require careful coordination across various facilities, equipment, and systems, often in different locations.

How do these advantages solve real-world challenges? Here’s a closer look at the practical applications of digital twins across industries.

Six universal business challenges solved by digital twins with real-life examples

Digital twins combine virtual testing, data-driven forecasting, and up-to-the-minute data to help companies solve tough business challenges. Below, we’ll look at real-life examples of how digital twins are being used in different industries.

Scaling production efficiently: A manufacturing digital twins case

Digital twins help companies smoothly move from small-scale prototypes to full-scale production, keeping quality high and maintenance costs down as they grow.

When companies expand production from a small prototype to a full-scale operation, they often need to modify or upgrade equipment and processes to handle larger volumes. Johnson & Johnson (J&J) tackled this challenge by using digital twins to simulate production across different scales. For example, they scaled up vaccine production during the COVID-19 pandemic.

Now J&J uses digital twins to improve production processes for pharmaceuticals and consumer goods, including liquids, creams, and gels. They test and model how their production processes will work for different product quantities and machinery, which:

- reduces development time

- minimizes costly physical experiments

- ensures product consistency across production levels

According to John Perrigue, ex-Senior Director of Smart Factory and Digital Twin at J&J, traditional methods allowed only a few physical experiments per week. In contrast, digital replicas make thousands of simultaneous simulated experiments possible.

Bring new products to market faster: A pharmaceutical case

By using digital twins, companies can test and refine new products virtually, speeding up development and getting products to customers faster.

In industries like healthcare, tech, and consumer goods, long development timelines can hold back innovation. British multinational pharmaceutical company GSK plc shortens the typical 10-year drug development cycle with digital twins. This saves them both time and costs to bring new products to market faster.

GSK created a digital twin model of their laboratory process, which helps:

- speed up development: Simulates biochemical reactions and shortens the drug development cycle

- cut costs: Reduces the $2.6 billion average cost of developing a new drug

- improve success rates: Identifies promising drug targets, combating the 96% failure rate

- enhance production: Tests process changes virtually before implementation

- refine screening: Uses machine learning to improve ADME-Tox analysis

Improving customer experiences in real-time: A retail case

Digital twins give businesses the ability to adapt instantly to customer needs, from optimizing store layouts to managing inventory on the spot.

Сustomer satisfaction has a direct impact on success in industries like retail. To keep up, stores need to adapt and optimize experiences in real time, from product placement to store layout, so they can meet evolving customer needs.

Lowe’s provides a great example of this. They partnered with Nvidia to create digital twins of their stores, which simulate customer behavior and help improve store layouts. These digital twins, accessible via computers and AR headsets, allow staff to:

- quickly check and adjust product placement

- visualize hard-to-reach items without using ladders

- simulate customer paths to optimize product placement

- plan and preview seasonal displays before implementation

Lowe’s applies digital twin tech to select stores. They focus on those that often change layouts for seasonal products.

Adapt and optimize operations for greater resilience: A supply chain case

Digital twins help companies make their internal operations more efficient and effective—while staying flexible. This means making quick adjustments when there are supply chain disruptions or sudden changes in demand, for example.

Staying flexible and responsive to demand surges, supplier issues, or logistical delays is critical to maintaining operational efficiency. Food and beverage manufacturer Kraft Heinz has taken this challenge head-on by creating virtual replicas of over 30 of its North American manufacturing facilities.

According to Carlos Abrams-Rivera, President of North America at Kraft Heinz, this technology “increases our dependability” and ensures product availability, even during global disruptions.

These virtual models stream operational, financial, and real-time sensor data, allowing Kraft Heinz to:

- manage inventory in real time, ensuring optimal stock levels across locations

- monitor equipment health and predict maintenance needs to prevent unexpected downtime

- adapt factory layouts and processes by digitally mapping facilities, increasing production efficiency

- better predict demand patterns and make quick adjustments to meet consumer needs and avoid shortages

This way, Kraft Heinz keeps their operations efficient, ensuring products reach consumers on time—even when faced with unexpected challenges.

Anticipate and plan for various scenarios across complex environments: A workplace management case

Digital twins help companies prepare for unexpected challenges by running simulations that show potential outcomes. This way, businesses can create effective contingency plans and run operations smoothly—even in uncertain situations, like health crises or environmental events.

Digital twins support predictive capabilities and strategic decision-making in situations that involve many moving parts or uncertainties. For instance, a company could:

- forecast potential disruptions in its supply chain, like delays or shortages, and adjust orders or production schedules to prevent stockouts.

- plan for weather-related risks by simulating the impact of a hurricane on their distribution centers, allowing them to reroute shipments in advance.

- optimize workplace safety by assessing potential health risks and creating safer environments for employees.

Tata Consultancy Services (TCS) used digital twins to develop safer return-to-office strategies during the pandemic. Their virtual replica of the workplace environment allowed them to predict virus spread and answer key questions such as:

- How many workers might be at risk of infection?

- Who should be tested, and when?

- What quarantine capacity might be needed?

By simulating these scenarios, TCS could make strategic, data-driven decisions to protect employees. This approach also ensured operational continuity.

Reduce testing risks and costs in high-stakes environments: An aviation case

Digital twins allow companies to test critical systems and train staff in a safe virtual environment, which saves costs and reduces risks involved in real-world testing.

In industries like aviation, finance, defense, and healthcare—where security is paramount—testing vulnerabilities can be risky and costly due to the sensitive nature of the systems. Physical tests risk exposing critical infrastructure to potential failure, high costs, and service disruptions. Digital twins allow companies to spot vulnerabilities without affecting real-world operations.

Boeing, for example, created a digital twin of its airplane systems to simulate cybersecurity threats. This virtual model acts as a flight simulator for cybersecurity experts. It allows Boeing’s team to train by playing both attacker and defender roles in a controlled, realistic environment.

This digital twin helps Boeing:

- save money on expensive physical testing

- train staff in realistic scenarios without risking aircraft safety

- spot and fix security weaknesses before hackers can exploit them

By providing a secure, cost-effective way to test defenses, Boeing’s digital twin helps protect aircraft from cyber threats, reinforcing the company’s commitment to safety and resilience.

Inspired by these examples? Discover how digital twins can enhance your business operations.

How do you know if your business can win from digital twin technology? Yalantis’ Solutions Architects, Mykhailo Maidan and Dov Nimratz, offer an insightful perspective. With years of experience bridging advanced tech with real business value, they’ve helped startups and industry leaders alike optimize their operations.

Will your business benefit from digital twins? Here’s a quick checklist from Yalantis experts

Digital twins offer a safe, cost-effective way to explore growth opportunities and tackle scalability challenges.

Use this checklist to see if digital twins could help your business:

✅ You manage a complex network of devices or systems and want a better way to monitor and optimize them.

✅ You frequently update workflows, equipment, or layouts and want a low-risk way to test changes.

✅ Unplanned equipment downtime is costly, and you want to predict maintenance needs before problems occur.

✅ Increasing operational efficiency is a priority for you (e.g., you need to speed up product flow through your facility).

✅ Your operations are high-stakes, and you need a way to safely test new strategies without real-world risk.

Mykhailo points out a key scenario where digital twins can make a real impact:

If several of these points resonate with you, it might be time to explore how digital twin technology could enhance your operations. Our experts would gladly chat about how digital twins might fit your business needs, so don’t hesitate to reach out.

Digital twin services: Navigating your software options

When it comes to digital twin solutions, you’ve got plenty of options. Some of the big players in this field include:

- Microsoft Azure Digital Twins

- AWS IoT TwinMaker

- Siemens Xcelerator

- GE Digital’s Predix Platform

If you want to dig deeper, we put together an in-depth analysis of their features, tech stacks, and industry suitability.

Get access to a comprehensive comparison table of top digital twin solution providers.

Grab it in seconds for freeCloud-agnostic framework to create digital twin solutions

Not all digital twins are tied to specific cloud providers. There are cloud-agnostic frameworks out there, like Eclipse Ditto™. These frameworks give you more flexibility in how you set up and run your digital twin system.

At Yalantis, we’re big fans of the Ditto framework. Here’s why:

- It’s cloud-agnostic, which is great if you don’t want to be locked into one cloud provider, or prefer to keep things on-premise.

- It lets you describe your devices in programming language, giving you a lot of control over how your digital twin operates.

- It’s open-source and constantly improving.

Using a framework like Ditto, Yalantis creates custom digital twin solutions that fit exactly what a company needs. Dov shares a recent example of how we put this into practice:

The result is a system that:

- synchronizes real-time data between physical devices and their digital twins

- allows for live message sending to digital twins, which then relay to physical devices

- supports direct method invocation on devices via Azure IoT Hub

The solution remains cloud-agnostic. If the client decides to switch cloud providers in the future, the core digital twin functionality won’t need to change.

Digital twin consulting: Your guide into the virtual world

If you’re interested in learning more about how we work with digital twins, our experts can give you the lowdown on Yalantis approach—just share your project details and we’ll book a call.

Besides, as part of Yalantis IT consulting services, our consultants can help you:

- build a solid business case to figure out if digital twins are right for your company

- navigate the tech landscape and choose the right technology stack

- select the best provider or framework for your specific needs

With the support of artificial intelligence consulting, we can also integrate AI-driven insights into your digital twin systems, ensuring they are not only accurate but also optimized for predictive analytics and real-time decision-making.

Wrapping up: Key trends in digital twin engineering

Let’s recap what makes digital twins so impactful:

- Real-time updates: They provide live insights, keeping you informed on your physical systems’ status.

- Advanced tech integration: By combining IoT, AR/VR, and AI, digital twins are more capable and accessible than ever.

- Cross-industry adoption: Digital twins are expanding into diverse fields and business functions, from retail and manufacturing to human resources.

- Predictive power: With enhanced diagnostics and forecasting, digital twins help businesses anticipate challenges before they arise.

If you’re excited about the possibilities but not sure where to start, our team at Yalantis loves exploring these digital frontiers with businesses just like yours. We’re happy to chat about how digital twins could fit into your unique operations—so feel free to reach out.

FAQ

What problem does a digital twin solve?

Digital twins provide businesses with virtual models to test, monitor, and optimize operations without impacting real-world systems. For example, they allow companies to predict issues (like equipment failures) through real-time data and simulate scenarios and test new workflows or layouts in a virtual environment before applying them live.

What are digital twin examples?

Here’s some examples from different industries:

- Automotive: A digital representation of a car with thousands of sensors, allowing the cloud to make decisions about the car’s performance and self-driving capabilities.

- Healthcare: A “smart insulin pump” that measures blood sugar levels and administers insulin, with a digital twin allowing doctors to monitor and adjust settings remotely.

- Industrial tools: Digital twins of machine tools in a factory, enabling remote monitoring and configuration.

- Logistics: Digital representations of delivery vehicles, allowing for better management of a large fleet.

What software is used for digital twins?

Various providers offer digital twin solutions:

- Major cloud platforms like Microsoft Azure Digital Twins, AWS IoT TwinMaker

- Industrial software companies like Siemens Xcelerator, GE Digital’s Predix Platform

Yalantis experts use cloud-agnostic frameworks, like Eclipse Ditto™. These frameworks give you more flexibility in how you set up and run your digital twin system.