Hardware Development Services

We transform concepts into manufacturable, cost-efficient devices. From complex PCB layout and FPGA design to BOM optimization and certification readiness, we ensure your hardware survives mass production.

Our hardware development services

-

Hardware & electronics engineering

Designing high-performance electronics with a focus on signal integrity and component optimization.

- Custom design of multilayer, HDI, and rigid-flex PCBs

- Circuit design, schematic capture, and simulation

- FPGA design and programmable logic development

- RF engineering and antenna tuning for BLE, Wi-Fi, LoRa, and cellular

- Power management and signal integrity analysis

-

Mechanical & industrial design

Engineering ergonomic and rugged enclosures ready for real-world operational environments.

- Industrial design, ergonomics, and 3D concept visualization

- Mechanical engineering and enclosure design

- Thermal management and heat dissipation simulations

- Ruggedization and IP-rated design for water and dust protection

- Rapid prototyping via 3D printing and CNC for validation

-

Embedded software & firmware engineering

Learn moreDelivering reliable low-level code for hardware control and real-time edge processing.

- Secure C/C++ and Rust firmware engineering

- RTOS and embedded Linux customization

- Board support package (BSP) and driver development

- Edge AI and digital signal processing (DSP) algorithm engineering

- Low-level optimization for battery life and performance

-

Manufacturing & certification support

Bridging the gap between R&D prototypes and scalable, compliant mass production.

- DFM and DFA optimization for cost-effective assembly

- Supply chain management and BOM optimization

- Production testing (DFT) and automated fixture design

- Pre-compliance testing for CE, FCC, UL, and RoHS standards

- New product introduction (NPI) and factory support

Hardware engineering solutions for various industries

Healthcare

Enhance patient care and streamline clinical workflows with connected medical devices, preventive care, and comprehensive process visibility.

Industrial

Minimize downtime, boost production efficiency, and improve safety with equipment monitoring and other smart manufacturing solutions.

Supply chain

Achieve complete visibility across your complex logistics networks, enable automated monitoring, and make better decisions at all stages.

Automotive

Improve performance and safety through advanced diagnostics and telematics. Enhance the driving experience while gathering valuable usage data.

Smart home & building

Reduce energy consumption, improve comfort and convenience, and provide peace of mind for your users with intuitive and reliable smart devices.

Hardware development process with Yalantis

Discovery & tech analysis

As a hardware development agency, we start by analyzing your business requirements and translate them into technical specifications.

System architecture & schematics

Hardware engineers design the complete electronic system architecture and create detailed circuit schematics.

PCB design & prototyping

We transform schematics into physical board layouts and produce initial prototypes.

Firmware development

Software engineers develop the code to power your hardware, from low-level drivers to application firmware.

Testing & certification

We conduct comprehensive testing to verify functionality, durability, and compliance with industry standards.

Manufacturing handoff & support

Your product is ready for mass production! We overview the process and provide ongoing support as the devices reach their users.

Challenges we solve

-

High manufacturing failure rates

Prototypes often work in the lab but fail on the assembly line. We apply strict Design for Manufacturing (DFM) principles to eliminate assembly errors and ensure high yield rates during mass production.

-

Supply chain & component obsolescence

Chip shortages and End-of-Life (EOL) parts disrupt production. We analyze your Bill of Materials (BOM) to select available, long-lifecycle components and design flexible circuits that support alternatives.

-

Certification delays

Failing compliance tests forces expensive redesigns. We conduct thermal modeling and pre-compliance testing early in the design phase to ensure you pass certification on the first attempt.

-

High unit production costs

Inefficient PCB layouts inflate costs at scale. We optimize board density, layer stack-up, and component selection to minimize the BOM cost without compromising device performance.

Success stories to show our expertise

Why partner with Yalantis

-

Proven track record in mission-critical domains

Leveraging 15+ years of engineering experience, we deliver OEM-grade hardware solutions for diverse high-demand industries. Trusted by global leaders like Bosch, Toyota, and RAKwireless to handle complex engineering challenges.

-

Manufacturing-ready design

We don’t just design circuits; we design for the assembly line. Our strict DFM (Design for Manufacturing) process ensures high yield rates, minimizes assembly errors, and reduces production risks from the first prototype.

-

Certified security & compliance

Work with an ISO 9001, ISO 13485 & ISO 27001 certified partner. We ensure your architecture meets strict industry standards (including medical & industrial protocols) from day one.

-

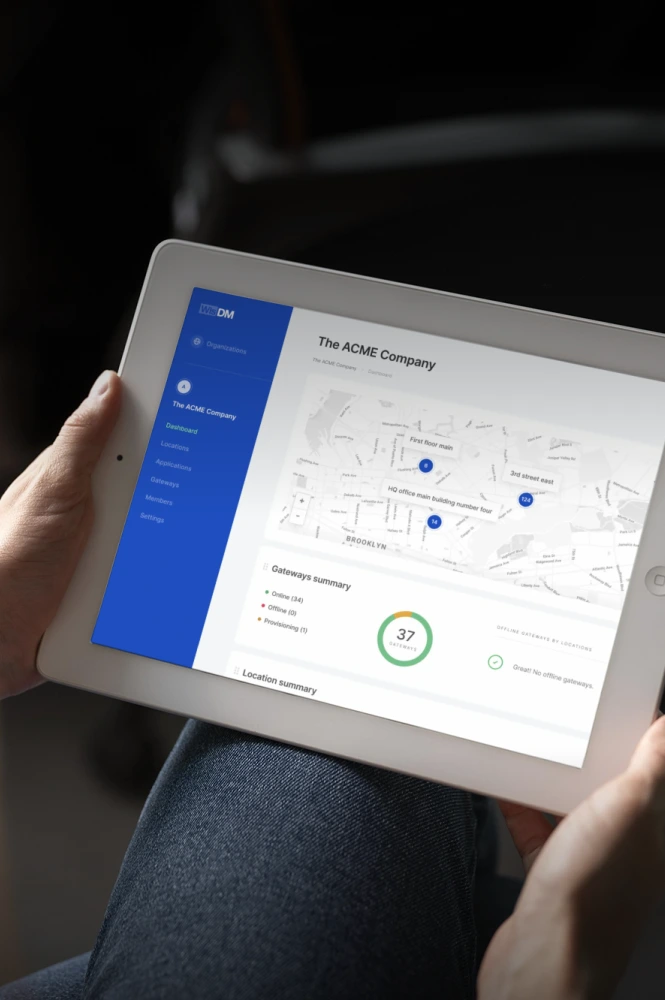

End-to-end hardware & cloud synergy

We bridge the gap between hardware and cloud. From firmware to mobile apps and IoT platforms, we deliver a unified ecosystem, eliminating integration headaches.

-

Designed for profitability

We design to maximize your margins. By optimizing hardware BOM costs and cloud resource usage, we ensure your solution makes business sense at mass scale.

Testimonials from our clients

FAQ

Can a hardware and software development company handle the full IoT product cycle?

Yes, a competent company can manage end-to-end hardware development, with software powering the gadget included in this process. Such firms provide comprehensive hardware engineering services and have all the professionals needed to cover the entire IoT product lifecycle from concept to deployment. This includes requirements analysis, hardware design, firmware development, cloud infrastructure, mobile app integration, obtaining certifications, and manufacturing support.

How long does it take for a hardware development company to deliver a finished product?

Hardware product development generally takes from 6 to 18 months, depending on its complexity. Simple products might be completed in under six months, while complex systems can take more than two years. The timeline varies based on requirements, regulatory approvals, manufacturing constraints, and design iterations. Our hardware experts can provide a more accurate estimate after reviewing your specific project needs.

What certifications should I plan for when using hardware development services?

You should consider FCC compliance for wireless devices, CE marking for European markets, UL certification for electrical safety, and possibly ROHS for environmental standards. Industry-specific certifications might include HIPAA for healthcare devices, automotive standards like ISO 26262, etc. If you want a more accurate list, contact our team to discuss your hardware plans in more detail.

Do your hardware engineering solutions include firmware for STM32 or ESP32?

Our engineering team develops firmware for both microcontrollers. We have extensive experience with STM32 and ESP32 and can implement everything from low-level drivers to complex applications. We typically recommend using STM32 for industrial and automotive systems. ESP32 is our go-to choice for connected products with wireless capabilities. Yet, we select the right microcontroller based on your project’s requirements.

What’s the best way to validate an idea before starting hardware design services?

It’s best to start with a proof-of-concept. This approach is a valuable asset in your development toolkit. For example, using development boards and modular components lets you validate the core functionality of a potential hardware product without investing the time or money that development requires. We recommend defining key technical hypotheses, creating simple prototypes, and testing with potential users.

Do you offer custom hardware development or only off-the-shelf solutions?

Absolutely. We offer custom hardware development tailored to your product’s unique requirements. Our team has deep expertise and hands-on experience delivering custom hardware development in Europe, the US, and other regions. Whether you need full project ownership, team extension, or a mix of both, we adapt to how you work.

Contact us

got it!

Keep an eye on your inbox. We’ll be in touch shortly

Meanwhile, you can explore our hottest case studies and read

client feedback on Clutch.

Nick Orlov

IoT advisor

How to get started with IoT development

-

Get on a call with our Internet of Things product design experts.

-

Tell us about your current challenges and ideas.

-

We’ll prepare a detailed estimate and a business offer.

-

If everything works for you, we start achieving your goals!