Over the last few years, logistics companies had gotten used to the gradual growth of the e-commerce market. However, the COVID-19 pandemic has exacerbated e-commerce sales and challenged the logistics industry.

According to Gartner’s research on the future of the supply chain, 69 percent of supply chain organizations expect that offline purchases will only decrease in the next five years. Thus, optimization of the whole supply chain system is especially relevant for logistics companies engaged in e-commerce. In this post, we discuss issues logistics companies are experiencing with cargo space optimization in storage and transportation facilities and share techniques on how to solve them.

E-commerce growth and its impact on the logistics domain

Closed stores and lockdowns forced even stubborn shoppers to buy online. According to Statista and eMarketer:

- US e-commerce revenue reached $431.6 million in 2020, increasing by 19 percent from $360 million in 2019.

- In 2020, global e-commerce sales reached $4.2 billion, an increase of 27 percent from $3.3 billion in 2019.

- In 2021, global e-commerce sales are expected to reach $4.89 billion, and by 2024, they are forecasted to reach a staggering $6.3 billion.

Amazon, the indisputable leader in e-commerce, has not only managed to quickly adapt to the new reality but to profit more than ever. According to Statista, in the first quarter of 2020, Amazon’s net sales revenue was $75.4 billion (a decrease of 13 percent from Q4 2019) and reached $125.5 billion in the fourth quarter of 2020 — the company’s highest quarterly turnover ever. Largely, Amazon achieved such success thanks to hiring 500,000 workers in 2020.

However, small and medium-sized logistics companies can avoid massive hiring and still benefit from the growing e-commerce market and achieve profit maximization with the help of the right technological solutions.

Take, for example, Red Stag Fulfillment, a small third-party logistics (3PL) company that fulfills niche e-commerce orders in B2C and B2B markets. In 2020, it was ranked among the four best fulfillment and warehouse companies in the US.

Red Stag Fulfillment got on this list along with the order fulfillment divisions of such giants as FedEx and Amazon. To stand out among competitors, Red Stag provides not only a solid customer compensation policy and lots of value-added services but also automated inventory planning software. This allows Red Stag customers to optimize space on the shelves they rent.

Red Stag provides just one example of the effective use of technical solutions for space optimization in logistics. Further in this post, we describe how a load space solution might help supply chain organizations effectively manage growing e-commerce orders. But first, we’ll view common issues related to logistics space management and then consider solutions to them.

Read also: Big data analytics solution for 3PL

Smarter space means better profits

Use logistics IoT development services to optimize every inch of your warehouse and transport network.

Key concerns with space optimization in the supply chain industry

We’ve compiled a few typical issues logistics managers face when dealing with space optimization during e-commerce growth. Let’s start with the challenges of storage space optimization.

Issues with space management in storage facilities

Insufficient storage space. Thirty-seven percent of respondents to the 2020 Warehouse and DC Operations Center Survey by Logistics Management admitted that insufficient space to accommodate growing e-commerce sales was one of the major issues impacting logistics operations. Between 2019 and 2020, larger order volumes increased the demand for more storage facilities of different sizes. These include warehouses, fulfillment centers (FCs), sorting centers, and distribution centers (DCs) located close to population centers. However, the problem with insufficient storage space can often be efficiently solved by optimizing available space.

Excessive inventory due to growing consumer demand. This phenomenon is known as the bullwhip effect. COVID-19 evoked unexpected demand for such goods as hand sanitizers, medical masks, and disposable gloves. According to Statista, as of May 2020, health and hygiene products were topping sales charts in the US, with demand having grown by 43 percent since the beginning of the COVID-19 pandemic. By contrast, as per an eMarketer survey, demand for apparel and accessories will increase by nearly 30 percent in 2021 compared to 2020. Such quick and dramatic changes in customer demand lead to the overstock of some goods and lack of others, causing lots of chaos in inventory management and product replenishment.

Read also: 5 Indicators Your Warehouse Management System Needs Improvement

Issues with space usage in trucks and containers

Space optimization helps businesses meet customer demands and deliver orders as they expect. According to a 2024 ShipStation report:

- 73 percent of shoppers state home delivery as their go-to option when purchasing online

- 55 percent of consumers expect order delivery within 48 hours after placing an order

- for 34 percent of consumerss cost of the delivery is major conversion factor whereas speed of delivery is crucial for 24 percent of consumers

Retail and delivery companies have to optimize their delivery practices to quickly deliver a growing number of orders in order to win and retain customers.

Shift to the B2C market and an increase in last-mile deliveries

More last-mile deliveries means a need for larger vehicle fleets with vans of smaller sizes to make routing in urban areas more efficient. Ultimately, this results in more expenses.

According to Statista, in 2020, the biggest last-mile delivery challenges faced by supply chain companies were reducing logistics costs and ensuring on-time delivery. These issues are only going to intensify, since last-mile deliveries are only expected to grow.

Shortage of truck drivers

A report by the American Transportation Research Institute states that a lack of drivers is currently the major issue in the trucking industry. This problem was intensified by COVID-19, as the pandemic caused demand for truck drivers to increase.

Therefore, even if logistics companies enhance their vehicle fleets to fulfill rising e-commerce demand, they can still struggle with hiring new drivers. Learn how to retain and attract new drivers with a robust fleet management system.

Let’s discover what could be an effective solution to all of the above-mentioned issues.

Technological solution to the space optimization problem

The essence of the space optimization problem lies in placing cargo in trucks, containers, and warehouses efficiently, taking into account major loading constraints.

For instance, to load vehicles and containers, you must ensure that all loads:

- are placed within the vehicle or container parallel to the walls and without overlapping

- are supported on all sides by other loads if they aren’t on the floor

- have six maximum orientations, excluding certain load types that have prohibited orientations

To allocate cargo in warehouses or other storage places, you have to consider the following constraints:

- Not every item can be stacked on top of others

- The positions of warehouse stacks are fixed

- Each stack has weight and height limits

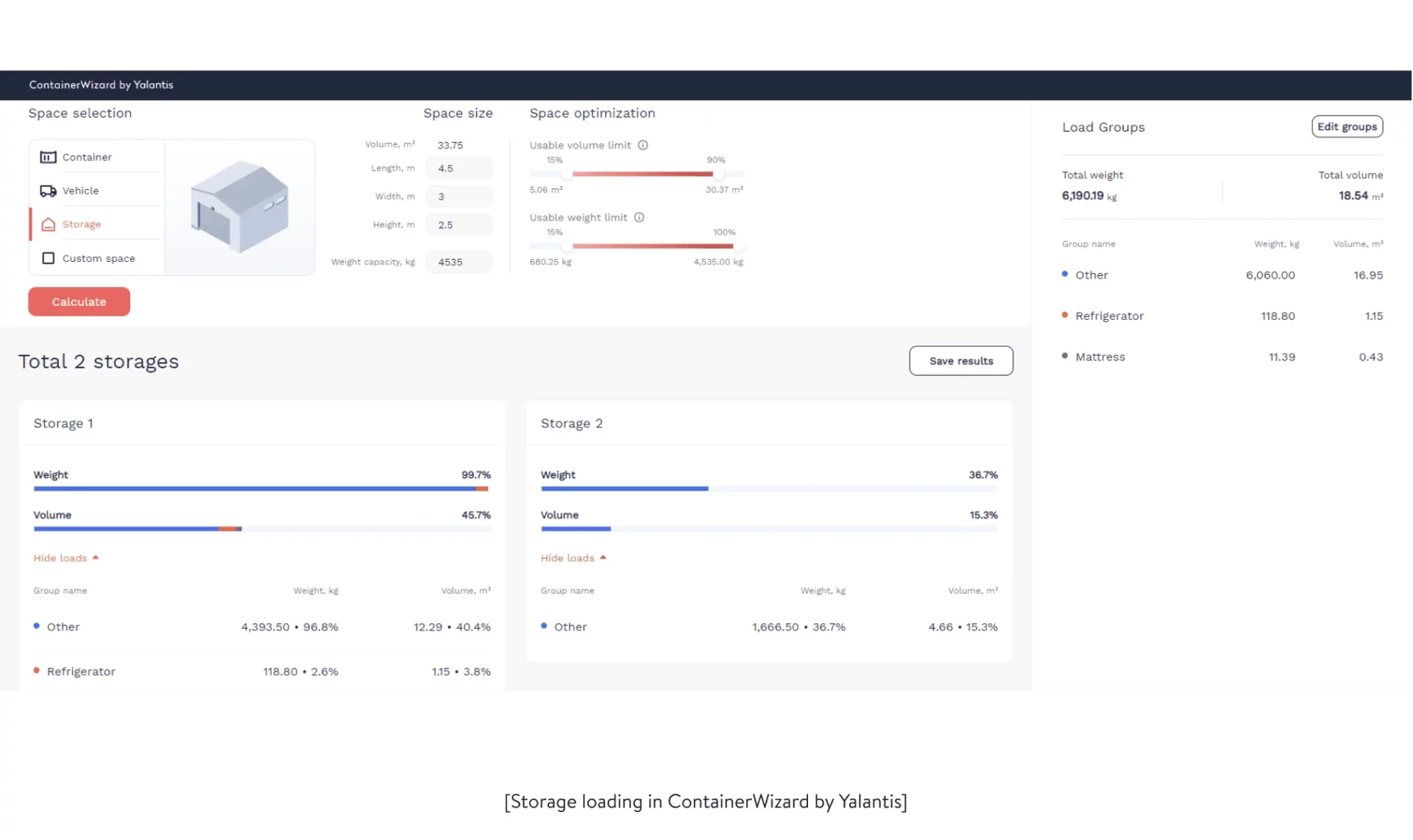

You’ll need lots of time and effort to deal with all these constraints manually, whereas a technological solution such as a load space calculator can automate space management in your organization. At Yalantis, we’ve developed a demo version of such a product that we call ContainerWizard.

Let’s find out how you can benefit from such a space calculator solution.

Benefits of a space calculator for your logistics company

With an appropriate technological solution for space optimization, you can fulfill more orders and reduce shipping and storage costs.

Automated space management in storage facilities:

- eliminates unused space and lowers operational costs on temperature control and illumination

- streamlines cargo distribution among your fullfillment centers, distribution centers, warehouses, and sorting centers through reduced manual labor

- reduces time spent picking items from the shelves by improved slotting, as a space calculator also allows you to view loads each storage space contains

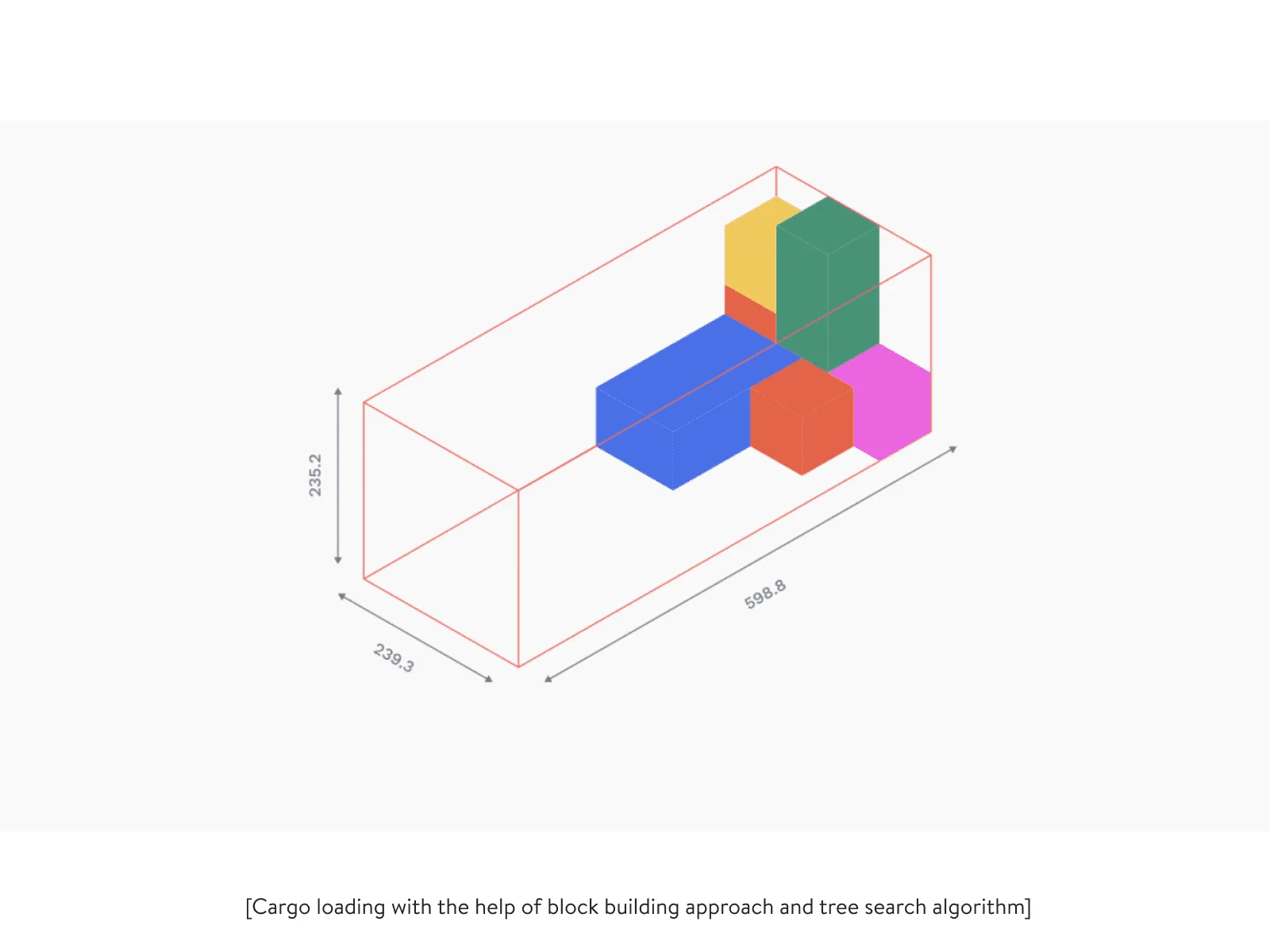

- improves storage layout and goods stacking. For example, in ContainerWizard, we’ve ensured this with the help of the block building approach and a tree search algorithm. Using the block building approach, load types of the same size are grouped into blocks. Then the tree search algorithm uses dimensions of the loading space along with parameters of blocks to calculate the optimal loading plan.

- simplifies inventory management thanks to quicker stock count and optimized allocation of goods after receiving them in the warehouse

If you maximize your storage spaces performance, you won’t need to lease additional space to fulfill a growing flow of orders. And with optimized inventory management, you’ll be able to efficiently manage goods replenishment.

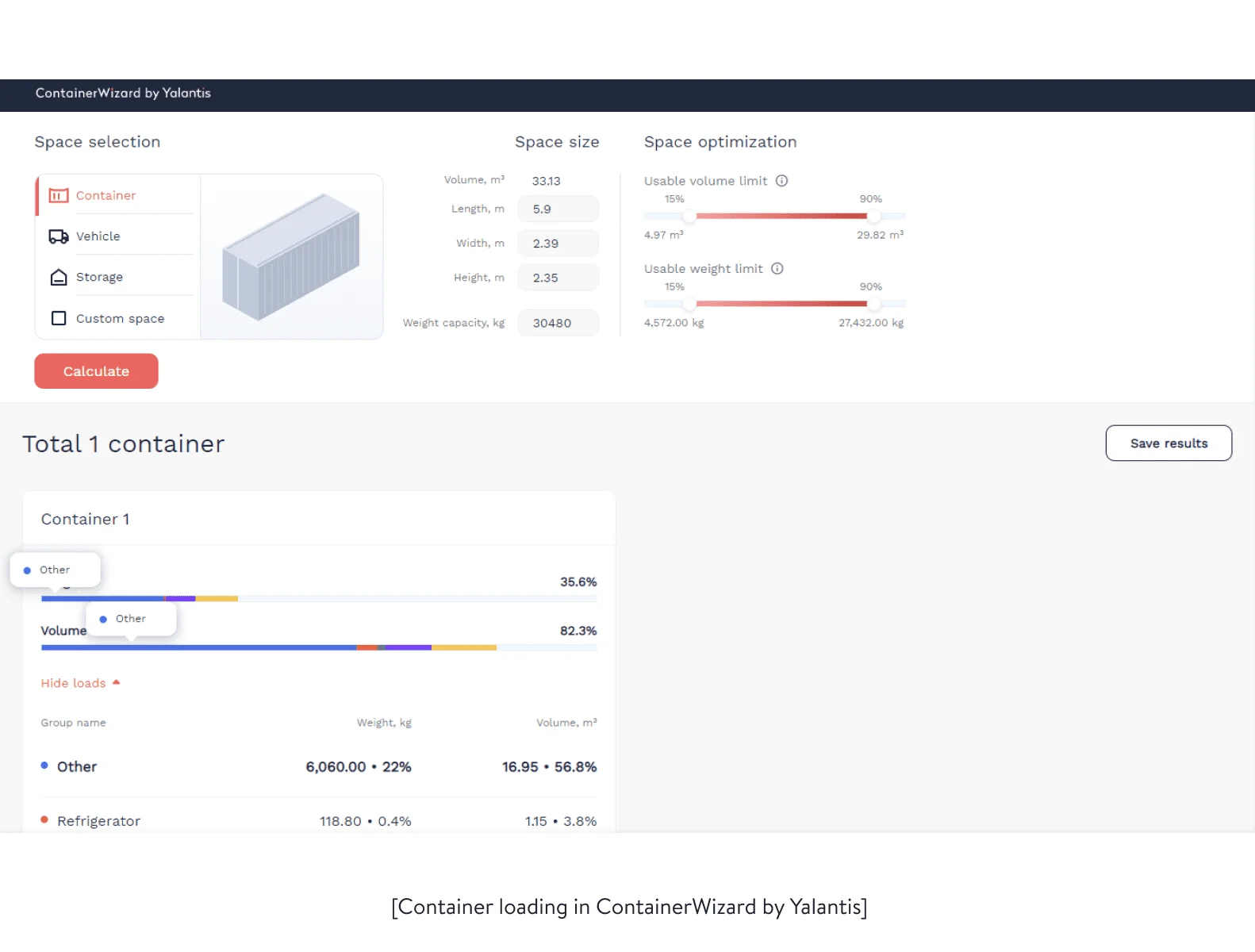

Below, you can see how to maximize warehouse space utilization and how storage loading can look in a space calculator.

Automated space optimization in trucks and containers can:

- improve fleet management and route building by assigning the right number of vehicles and containers for a certain shipment and by knowing each truck’s load

- help to deliver more parcels in fewer trucks and containers and cut last-mile delivery costs thanks to the optimal distribution of orders among vehicles

- maximize the space capacity of each truck and container with the help of a calculated loading plan, decreasing the need to hire more workers like truck drivers

- simplify cargo loading and unloading by means of a last in, last out order of goods in trucks and containers

- reduce time on load planning and minimize delivery delays thanks to decreased manual processes

With faster deliveries and fewer delays, you can increase customer loyalty and efficiently serve both B2B and B2C markets.

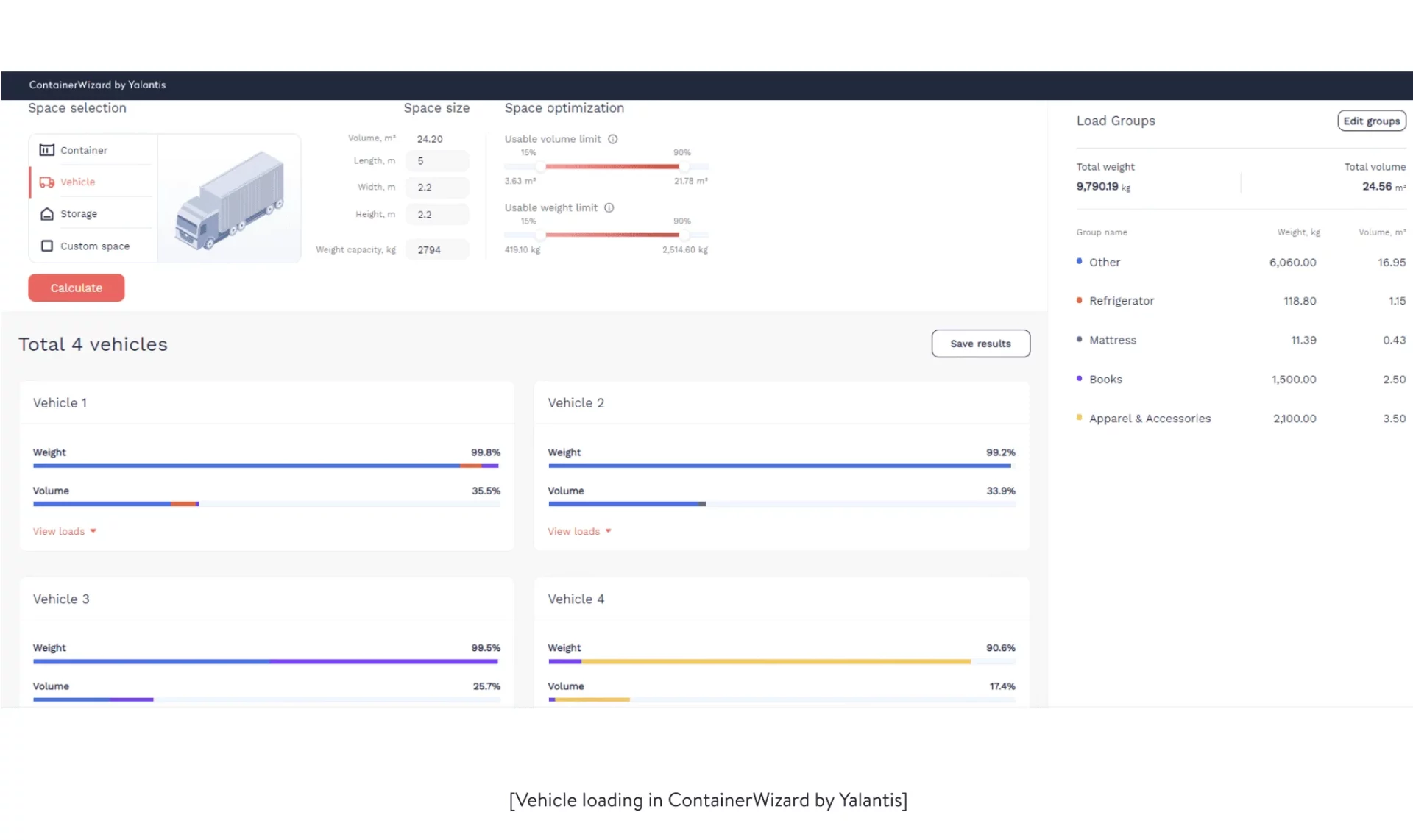

Here is what load distribution among vehicles might look like in the load space calculator. We can see that we need four trucks to transfer our cargo. Plus, we can view the type of load each vehicle carries.

Read also: Load space calculator for supply chain businesses

You can also make the same calculations for optimizing containers space.

The above lists of possible benefits can be extended depending on the specifics of your processes, the products you store and deliver, etc. However, it’s undeniable that efficient use of space can result in profitable outcomes for your business.

Read also: Our recent project for calculating containers needed for delivering materials to manufacturers

What to consider when building a custom space optimization tool

Before you embark on building custom space optimization software, be sure to decide on the software’s core functionality and determine what integrations are needed.

Decide on core functionality. Identify which logistics goals you’ll meet with the help of space calculations. These goals might include efficiently loading shipping containers or maximizing the cost-effectiveness of freight forwarding. Depending on your goals, you’ll be able to decide on relevant features for your space optimization tool. For example, if you want to optimize storage loading, then goods stacking functionality can be beneficial. For transportation needs, you’ll probably require goods compatibility tools and need to consider specific requirements for transferring bulky, heavy, and fragile cargo. You might also include 3D modelling of load distribution in vehicles, containers, and storage places to know the exact positioning of your loads.

Define the necessary integrations. A load space calculator usually integrates with a transportation management system (TMS), warehouse management system (WMS), fleet management system (FMS), and material requirements planning system (MRP). For instance, if you integrate a module for space calculations with your TMS, you can build more elaborate dispatch routes with fewer trucks. Space calculations in an MRP can facilitate better inventory forecasts for your storage locations.

If you need a technical solution to your space optimization problem, we’d be glad to build it for you, taking into consideration your delivery and storage needs. Yalantis has vast experience developing complex logistics systems. We’ll identify and build an effective software solution tailored to your business specifics.

Need space optimization in your supply chain system?

Check out our load space calculator that efficiently solves space optimization problem