Digital transformation in supply chain management isn’t about adopting new technologies. It also isn’t about chaotically automating certain processes while leaving others siloed. Rather, it’s about continuous improvement at the enterprise-wide level with IT technologies as enablers of your forward-looking business goals.

We won’t lie to you: DT is a hard undertaking and requires preparation before it can take off. But it’s definitely worth it. Procter & Gamble conducted a survey and revealed that 70 percent of DT attempts fail. Tony Saldanha, a former VP of Procter & Gamble with 27 years of experience running IT operations at the company, mentions this in his book Why Digital Transformations Fail.

Would you bet your money on something with only a 30 percent chance of winning? We doubt you would. But in the case of logistics digital transformation, it’s not fate or luck that defines your success but rather you (as a company executive) and your employees.

In this article, we challenge common stereotypes about DT, show you the real value IT transformation roadmap can add to your business as well as answer an important question: what is digital transformation in supply chain? We also provide you with some tips to help you increase your chances of winning by creating a feasible supply chain transformation roadmap for years to come.

Need a technical partner with supply chain experience?

Optimize your logistics processes and streamline your transportation and logistics software with Yalantis

Digital transformation: an option or a necessity for the supply chain domain?

If you want to stay relevant on the market, change is a necessity, not a choice. The fourth industrial revolution and the pandemic are pushing supply chain companies to adapt, change, and become resilient.

Industry 4.0 impact

Industry 4.0, or the fourth industrial revolution, requires implementing disruptive technologies in the current business structure from top to bottom. Industry 4.0 aims at digitizing every aspect of the supply chain (from manufacturing to delivery) and as a consequence enhancing supply chain visibility and efficiency for everyone involved. Yet no matter how promising this sounds, many businesses still choose to rely on familiar (legacy) business practices. A 2021 Industry 4.0 Survey by BDO among 100 C-level manufacturing executives revealed that:

- 74 percent of respondents belong to legacy manufacturers, ranging from those who have a digital transformation roadmap but are not yet implementing it to those who don’t even plan to change and want to leave things as is

- 24 percent of respondents belong to “reborn in digital” manufacturers, meaning they’re sticking to industry 4.0 principles

An interesting fact from the same survey is that digital manufacturers are planning to actively invest in DT in the next 12 months. The reason for this could be that 96 percent of their previous DT initiatives have turned out successful. On the other hand, legacy manufacturers plan to invest less, which is logical, as historically only 47 percent of their DT initiatives have been successful.

The root cause of this imbalance may be that digital manufacturers already know what it’s like to reap the benefits from digital initiatives, spurring their confidence to continue. Meanwhile, legacy manufacturers may be too pessimistic to continue because of their previous failures.

When you begin with digital transformation in logistics industry, you should decide from day one that you’ll proceed despite any failures. After all, we’re certain that digital manufacturers who are now successful have also gone through unpleasant experiences with failure at the very beginning of their DT journey.

Apart from industry 4.0, the COVID-19 pandemic has been a very disruptive event that has forced many logistics businesses to begin their digital journeys.

COVID-19 pandemic impact

Among more than 200 supply chain professionals surveyed by ToolsGroup in 2021, only three percent of respondents said that the pandemic had not impacted their organization. COVID-19 has caused challenges for the supply chain domain by:

- revealing process vulnerabilities

- causing supplier instability and inconsistency

- leading to increased demand for which companies weren’t prepared

As a solution to these issues, 42 percent of respondents to the ToolsGroup survey said they had accelerated their supply chain digital transformation strategies.

A roadmap to digital transformation is considered the most effective cure for the majority of COVID-caused disruptions.

Digitally inflexible organizations are now in an especially tough situation. On the one hand, the pandemic has intensified most of their current supply chain issues. On the other hand, their competitors are actively acquiring industry 4.0 strategies and getting stronger. Now is the time for decisive actions based on a coordinated digital transformation strategy roadmap to survive and thrive in the market regardless of your company’s size.

How small and midsize companies can benefit from digital transformation

There’s a common stereotype that digital transformation in logistics is such a groundbreaking process that it’s suitable only for large enterprises with dozens of departments and thousands of simultaneous processes. As you may have guessed, that isn’t true. A 2021 Digital Transformation Trends report by SMB Group reveals the percentage of 761 North American small and midsize businesses (SMBs) that are already executing DT:

- 65 percent of companies with 100 to 2,500 employees

- 47 percent of companies with 20 to 99 employees

- 29 percent of companies with 1 to 19 employees

SMBs can drive much value from digital transformation framework, and here’s why:

Real-life examples of successful digital transformation in logistics

The examples of small, midsize, and large companies below prove that supply chain management digital transformation is beneficial for organizations of any size if they aim at becoming more customer-centered.

Small company

Red Stag Fulfillment, a 3PL company with 19 employees, is adopting leading technologies to offer its clients exceptional cloud-based order fulfillment services. Red Stag clients can access real-time dashboards (from any device and at any time) with all crucial information about their inventory.

For six years in a row, Fit Small Business, a leading digital content resource for small businesses, has recognized Red Stag Fulfillment for providing the best fulfillment services for high-value, large, and specialty goods.

Midsize company

ShipBob is another tech-driven 3PL company (with 469 employees) that provides order fulfillment services. The company offers multiple software solutions including order management and inventory management systems along with reporting and analytics software.

The company’s inventory management system sends ShipBob clients timely reminders if stock needs to be replenished. Reporting and analytics software shows, for instance, the impact of promotions on inventory levels as well as generates reports based on such data as fulfillment cost per order and storage cost per unit.

We helped a 4PL logistics company digitize their processes. Check out the case study to know how we built a solution to automate the company’s delivery management.

Large company

The smart logistics company Echo Global Logistics, with 2,593 employees, provides a whole technology suite with EchoShip, EchoDrive, EchoConnect, EchoTMS, and other solutions. A TMS is one of the core solutions for better logistics management. Read the case study to learn how we create this type of software.

- EchoShip is a web portal for shipment booking and real-time shipment status updates.

- EchoDrive is software that functions as a web portal and a mobile application for carriers and drivers. On the web portal, carriers can efficiently manage loads. Using the mobile app, drivers can provide real-time location tracking and don’t need to make any check-in phone calls.

- EchoConnect and EchoTMS provide analytics and shipment visibility functionality, respectively.

DT can help you surpass your clients’ expectations and make their interactions with your company as simple and convenient as possible. Consequently, you’ll stay relevant on the market for a long time, no matter whether your company is small or large. So how to create a digital transformation roadmap?

Groundwork before building a digital transformation roadmap

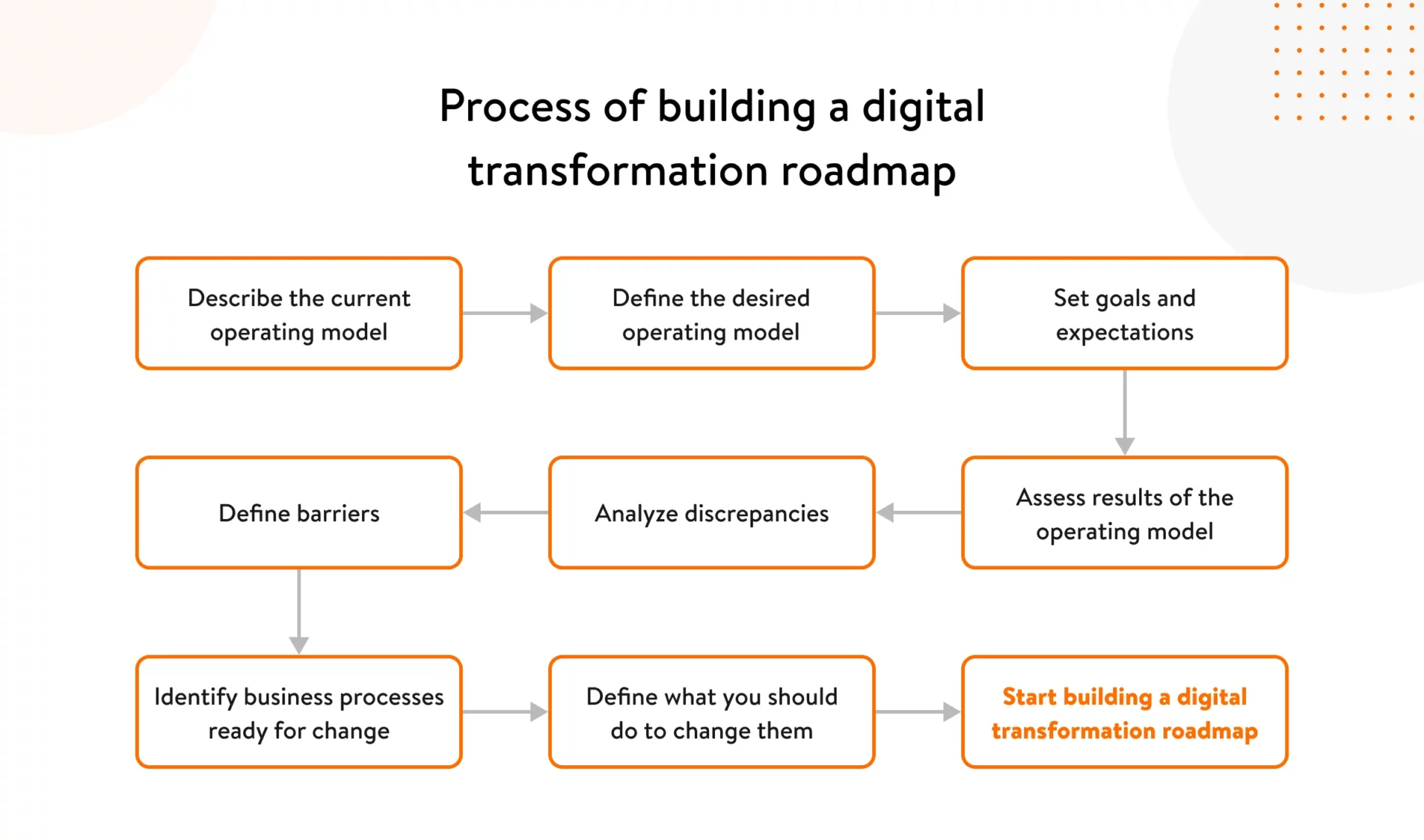

If you feel now is the time for DT, we’ll share with you a few ways to get ready for building a feasible digital transformation roadmap in the supply chain. A roadmap is the last element you need before you actually start your digital journey. And prior to building your roadmap, you should define your current level of digital maturity.

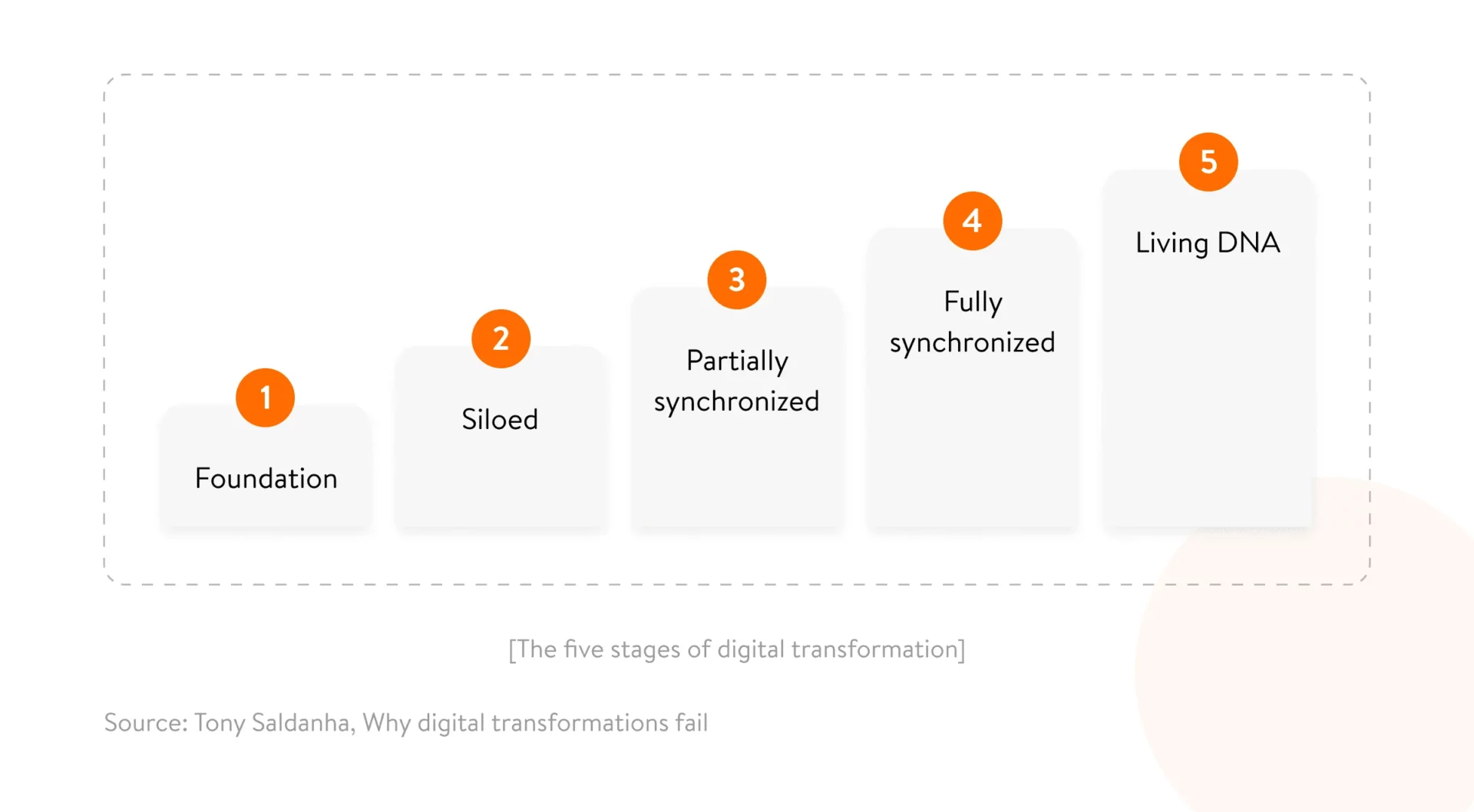

As-is state analysis: five stages of digital transformation

Tony Saldanha offers five digital transformation stages in his book Why Digital Transformations Fail, and they’re useful so you can see where you’re currently at in order to start in the right place. If you realize that your company hasn’t even reached the first stage yet, you can still learn what awaits you if you step on this digital journey.

1. Foundation stage

At this stage, a supply chain company has automated only certain manual processes by implementing discrete digital software solutions such as:

- enterprise resource planning (ERP) systems that SAP and Oracle provide

- manufacturing execution systems (MESs) for better management of manufacturing processes

- warehouse management systems (WMSs) for visibility of stock levels

Still, at this first stage, most of the supply chain data is paper-based and digital solutions aren’t at the core of the business culture.

2. Siloed stage

At this stage, certain business units within the supply chain organization are adopting disruptive digital solutions like cloud computing, blockchain, AI, machine learning (ML), IoT, and robotic process automation (RPA). Adoption of these technologies isn’t at the enterprise level but rather at the level of separate departments that don’t exchange much data.

For instance, the freight management team may decide to install IoT sensors in shipping containers to track their location and get data on temperature and humidity levels as well as any movement to prevent theft or damage to goods.

3. Partially synchronized stage

At this stage, the company’s C-level executives have a clear vision of the whole organization’s digital future. Having automated manual processes and experience with leading technologies, managers can move towards gradual synchronization of siloed digital departments so they can exchange insights to get closer to complete supply chain visibility.

For instance, in a partially synchronized organization, two major supply chain management processes, such as transportation and warehousing, are fully coordinated. Stock replenishment corresponds to the number and frequency of orders and deliveries. Trucks are loaded and unloaded according to the schedule, as warehouse operators know the exact location of all orders on the warehouse shelves.

Read also: Space Optimization in Storage and Transport Facilities amid the E-commerce Boom

4. Fully synchronized stage

If a company is fully synchronized, it means that all of its departments are digitized and integrated with each other. This stage suggests that the supply chain company has finally reached that much-anticipated goal of complete supply chain visibility. However, the company’s position isn’t stable yet, as adoption of any new technology or issues with technologies already in use can potentially disrupt the supply chain management process.

5. Living DNA stage

At this stage, you become a digital leader. Tony Saldanha calls companies at the living DNA stage “disciplined innovators.” DT is ingrained in their business culture, and there is no way for them to fall back on the previous stage. Such companies drive the whole supply chain industry forward and serve as role models.

Taking into account the above-mentioned stages, we can outline the following digital transformation process steps:

You can build a DT roadmap regardless of your current digital stage. Even if you’ve digitized a few processes, you can aspire for new digital heights. And most likely, you’ll need to periodically (annually or quarterly) conduct strategy reviews that can help you see if you need to alter your initial plan based on your current achievements.

After analyzing where you’re currently at, you can start gradually nurturing or enhancing a change in mindset within your organization.

Building a changed mindset within the organization

Change is disruptive and frightening, yet necessary. John Kotter, a Harvard professor of business, has developed an eight-step process for leading change in an organization. We’ll have a look at each step in detail.

Step #1. Create a sense of urgency

This step is taken by C-suite executives, who have to make it clear to everyone in the organization that it’s important to seize the opportunity right now, given, for instance, the industry 4.0 disruptions. This idea will unite everyone and set change as a priority. During this step, the top management team also has to discuss the possible consequences of success and failure.

Step #2. Build a guiding coalition

At each organizational level, there should be leaders who support the change initiative and who are eager to contribute to it. The members of this coalition should freely exchange ideas with each other to facilitate the change process.

Step #3. Form a strategic vision

A proper strategic vision should motivate people, coordinate their actions, and clarify for everyone how the future can be different from the past and the present. Plus, a vision should transform into actionable initiatives that can help to make the future a present reality.

Step #4. Enlist a volunteer army

As a company executive, you have to ensure that everyone in your change coalition is free to offer solutions and take actions, and, most importantly, you have to make sure that everyone genuinely wants the change you’re pushing for. You can achieve this by motivating your team. But don’t try convincing someone, as whenever you’re convincing, you’re losing.

If you realize that you don’t have a sufficient number of committed people, you can hire them. Afterward, you can make digital readiness an important element of your recruitment strategy.

Step #5. Enable action by removing barriers

Identify barriers that prevented your organization from changing in the past. Then see if these past barriers are still relevant in the present. Such barriers may include a hierarchical organizational structure that makes it difficult to voice opinions to leaders. Another barrier could be employees that don’t want to abandon their legacy work approaches, like using Excel spreadsheets to manage procurement data. In the latter case, you’ll need to find a way to encourage these employees to change — for instance, by means of training and benefits that can make thе transition period smoother.

Step #6. Generate short-term wins

Track any progress on the way to change, no matter how big or small. Your wins can be anything from lessons learned to improved processes, new practices, or behavior patterns your team adopts. Due appreciation of your team’s achievements on the way to disruptive change will keep your team motivated and fuel their confidence, giving them strength to take action even in the most challenging environment.

Step #7. Sustain acceleration

Keep in mind your initial vision and stick to a critical approach even after a few promising wins. Consistency is the key to permanent growth, and it helps you train your mind to be alert for any inefficiencies that need to be improved. You should also continue expanding your volunteer army with new committed people who can help you spot more and more barriers that are hindering your organization’s growth.

Step #8. Institute change

Build a deep-rooted culture of change in your organization. With changed processes and principles, you can create a whole change management network that will function as a self-sufficient element of your organization.

A proper change mindset in your organization and discipline can help you build a feasible technology transformation roadmap and may even help you to leapfrog a few stages of your DT journey to become a digital leader faster.

Final tips to prepare for the digital transformation journey

In this last section, we give you a few tips to keep in mind before and while building your DT roadmap.

Tip #1. First comes business, then technologies

Always consider your business needs, business culture, and goals as drivers for choosing digital technologies, not the other way around. DT can help your company thrive only if you align it with your unique business strategies.

Tip #2. Focus on your company only

You may, of course, follow the example of digital leaders in supply chain transformation, but remember that there’s no guarantee that what works for them will work for you. Find your strengths and cultivate those first, especially if your company is small or midsize.

Tip #3. When adopting new technologies, consider the people who will use them

Prepare your employees to adopt new technologies they’ll use daily. Train your employees to use these technologies even before you implement them to minimize frustration and anxiety. Besides, you can even consider training your people with the help of e-learning solutions and making custom training programs a part of your DT strategy.

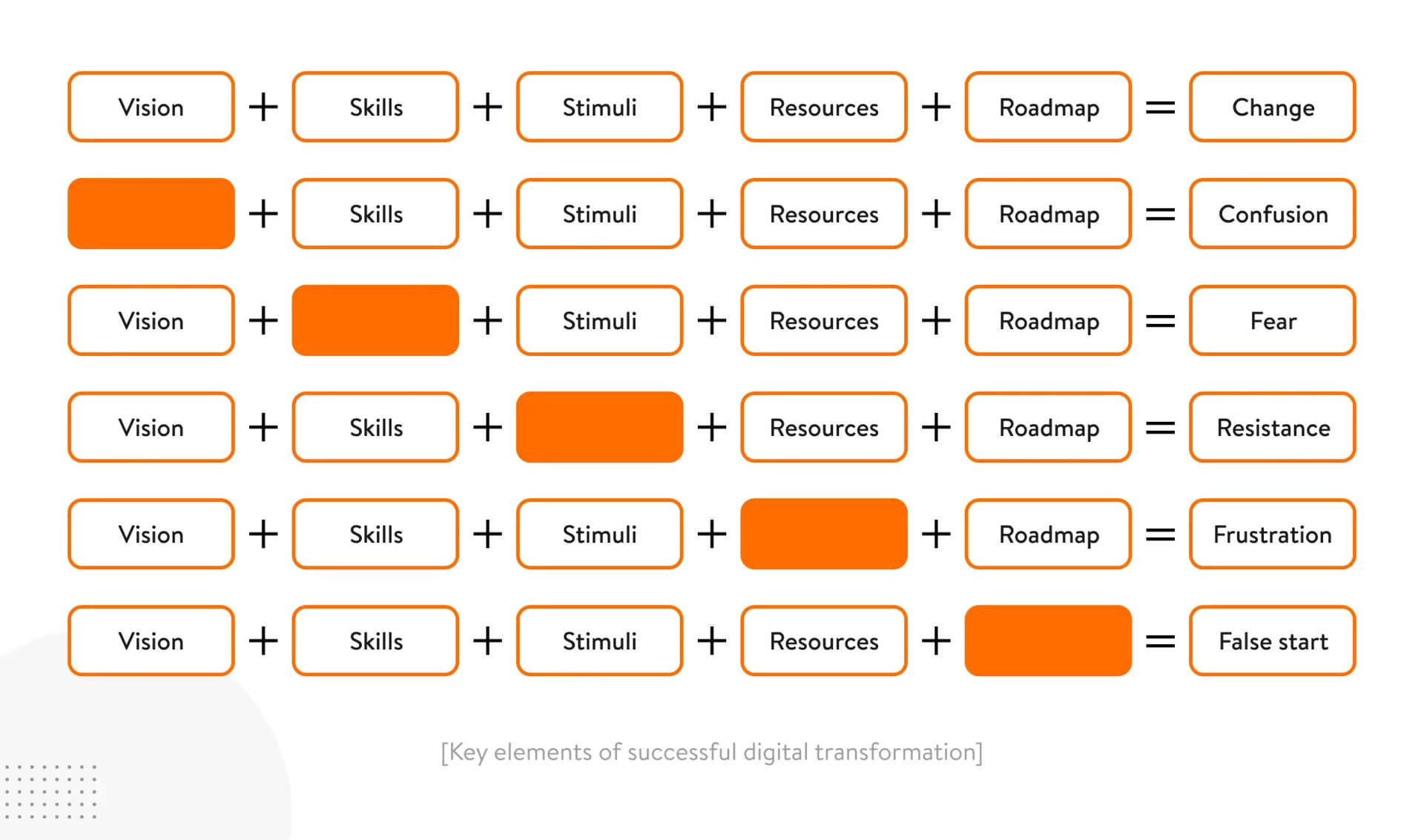

Tip #4. Ensure you have five key elements that can help you change

Below is a chart which shows that all these elements are necessary for the success of your DT initiatives:

- a clear business vision

- your committed team’s skills

- external and internal stimuli (external like industry 4.0 and internal like increasing operating expenses)

- financial and human resources

- a feasible DT roadmap

A roadmap shows you the most efficient way towards digital transformation and, most importantly, helps you visualize your DT journey.

DT isn’t one disruptive step you should take in one go but rather a gradual and incremental improvement process that doesn’t require you to invest all of your resources from the very beginning. But one important reminder — once you start going down this path, there’s no way back. To remain in the ranks, you must only go forward despite any difficulties.

Don’t know where to start with your digital transformation journey?

We can build a custom roadmap for you.

FAQ

What is logistics digital transformation?

In logistics, digital transformation can take place in different ways. They include: 1) implementing technologies to smoothen the flow of data and materials inside and between organizations; 2) utilizing digital technologies to facilitate the customer experience; 3) adopting digital technologies to make business processes more efficient; 4) using digital technologies to build new business models.

What is a digital transformation roadmap?

It’s the series of steps that should be taken by the company to accomplish short-term and long-term business objectives by utilizing digital technology.

What are the benefits of supply chain digital transformation?

Effective supply chain digital transformation leads to business growth, reduced risks, and optimized costs. Digital transformation ensures more efficient operations and improves decision making.

Rate this article

5/5.0

based on 1,185 reviews