The industrial sector consumed a massive 37% of global energy in 2022. Yet, many facilities are still running blind on where and how that energy is being used — or worse, wasted. Luckily, IoT energy management is changing that with real-time monitoring and automation.

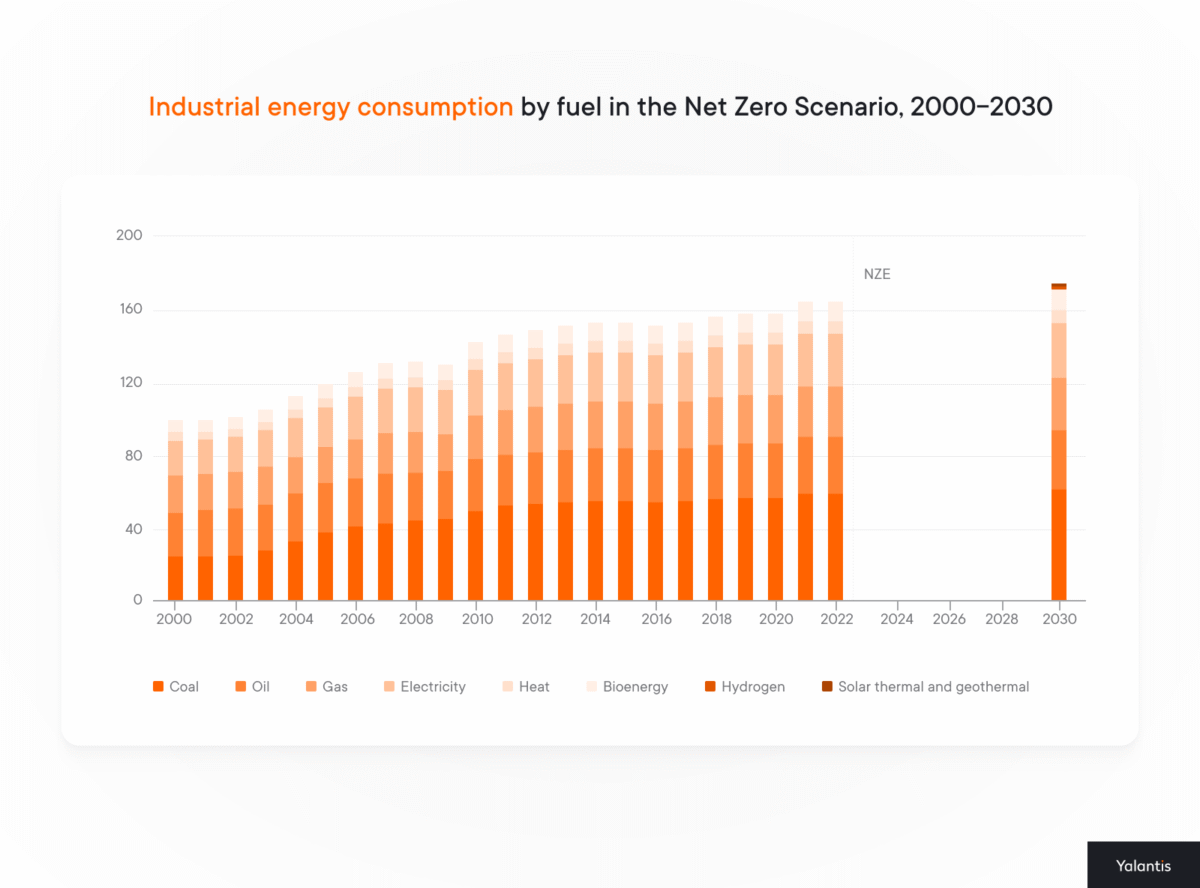

Adopting energy efficiency technologies like IoT, renewables, and electrification could deliver over 80% of the emissions reductions needed to meet the 2030 Net Zero goals. And with the IoT in the energy market set to more than double — from $30 billion in 2024 to $63 billion by 2030 — the shift is already underway.

If you’re looking to cut energy consumption and costs, read on to explore:

- What IoT brings to energy efficiency

- How a software solution by Yalantis reduces energy waste by 30%

- Which IoT energy management challenges to expect — and how to overcome them

- What the future looks like for smart energy management

Highlights:

- Benefit from real-time and condition-based monitoring across machines and power lines.

- Spot idle equipment draining power — even when it looks “off.”

- Get early ROI with custom dashboards tailored to your facility.

- Automate alerts to identify abnormal usage and prevent downtime.

- Easily integrate with legacy energy systems, SCADA, and ERP platforms.

Want to cut energy expenses across your operations?

Explore our case studyWhat IoT brings to industrial energy monitoring

Traditional energy monitoring in industrial settings is often outdated, siloed, and far from actionable. In turn, with IoT in energy management, you get a real-time, connected, intelligent system that helps you control power consumption, reduce energy costs, and cut waste.

Such systems typically combine smart sensors, connected meters, and cloud-based dashboards. Here’s what that looks like in practice:

Real-time power consumption monitoring

Know what’s happening with your energy at the very moment. In particular, we let facilities monitor consumption in real time through:

- Connected meters that enable live energy usage tracking across machines, lines, and departments

- Dynamic dashboards with charts, tables, and animations to visualize trends, as we did in the stromee project

- Integration with PowerCloud for secure, synced energy data storage

Besides that, real-time monitoring means you can identify peak usage patterns, idle loads, and wasteful processes on the spot.

Condition-based monitoring

Don’t wait for something to break — respond to inefficiencies as they occur. Condition-based monitoring means you constantly scan your systems to detect issues and find smarter usage patterns. Key capabilities include the following:

- Automatic detection of abnormal consumption spikes

- Alerts for out-of-pattern equipment behavior

- Data-driven shutdowns of idle or underperforming machines

- Meter reading history, recorded by both inspectors and users

- A custom consumption calculator like the one we’ve built in stromee for better load management

Smart energy alerts & automation

Energy monitoring becomes much more efficient when it’s proactive. With IoT, you can set consumption thresholds, define what’s “normal” for your facility, and get automatic alerts when something’s off. For example:

- Energy usage threshold setting across devices and facility zones

- Real-time alerts for overloads, anomalies, or system faults

- Automated responses like power redistribution, equipment recalibration, or maintenance prompts

And as your system evolves, our AI and ML-powered IoT Accelerator can take it even further. Here’s how. Machine learning models can learn to forecast energy consumption based on historical use, time of day, and other factors. AI capabilities, in turn, can automate things like equipment usage rescheduling, maintenance, you name it.

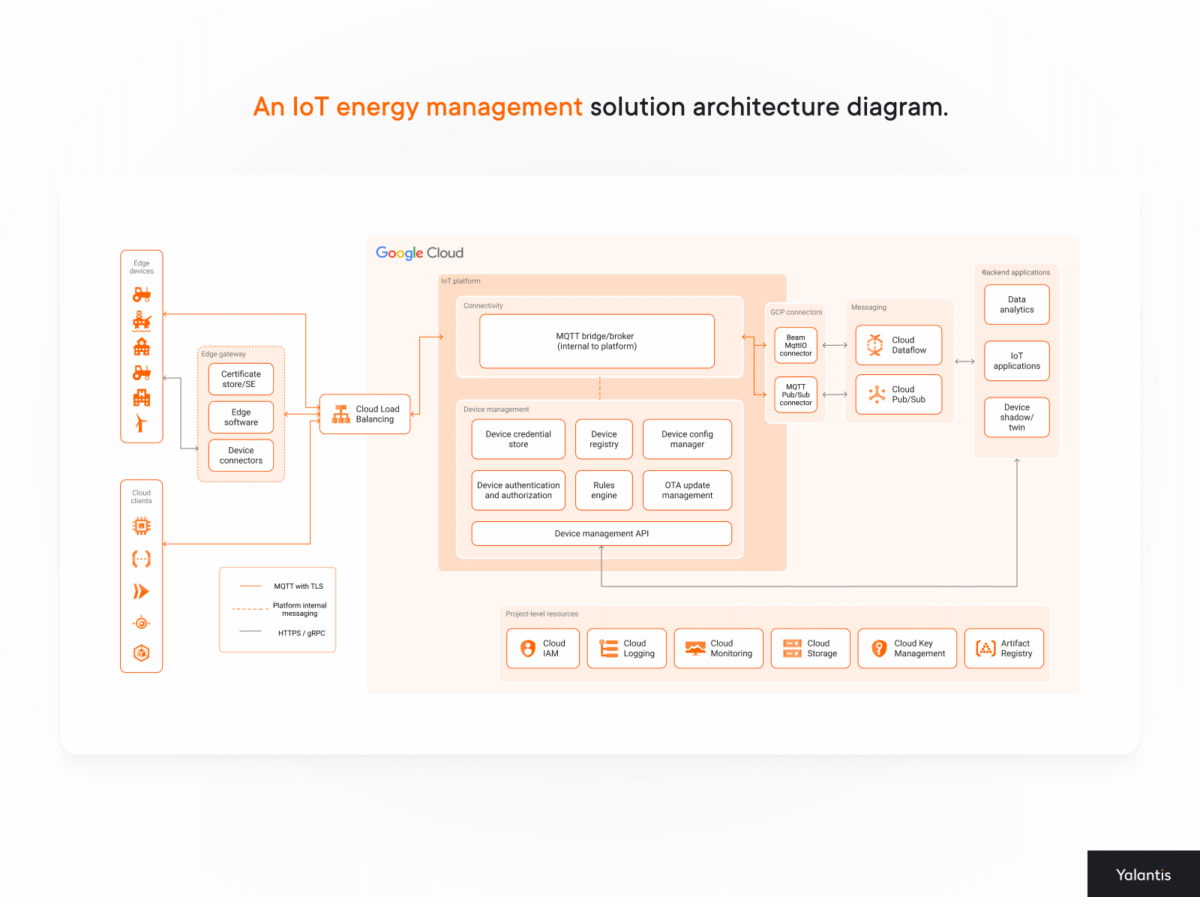

Unified data architecture

An IoT energy monitoring system connects everything and gives you a complete view of your facility’s processes. That’s possible through the following:

- API-first design for smooth integration with ERP and EMS

- Facility-wide visibility across multiple systems and locations

- Compatibility with SCADA, BMS, and legacy industrial systems

Case study: Conscious energy consumption platform by Yalantis

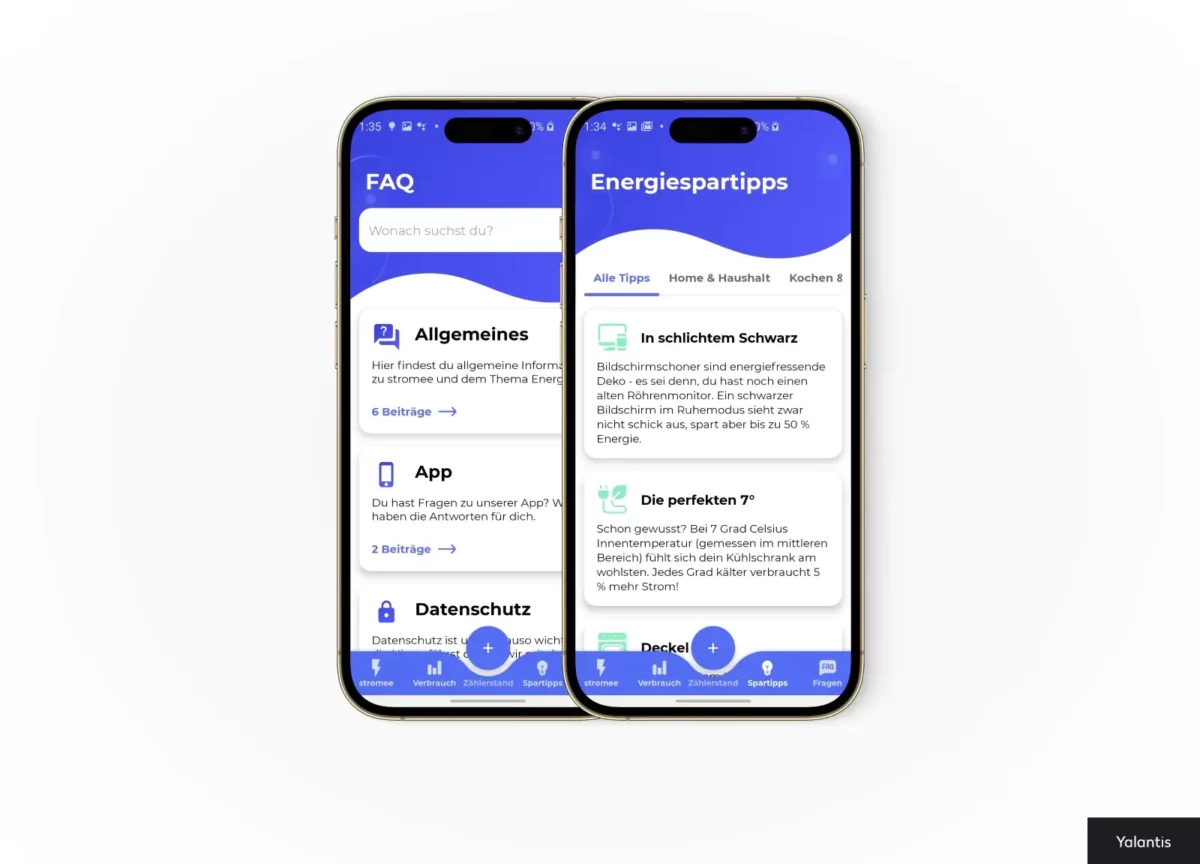

Our client, stromee, a renewable energy business, needed an energy consumption monitoring platform to help people become more mindful of their energy usage. In particular, they required a web and mobile solution that would cover the following:

- Stand out in a crowded market of electricity providers.

- Educate and engage users around conscious energy consumption.

- Offer clear, user-friendly benefits to gain market share rapidly.

As a solution, we delivered a custom suite of tools that made it easy for consumers to track, understand, and optimize their energy use — all while reflecting stromee’s modern, eco-conscious brand. Those included:

- Device integration and custom firmware. We developed custom firmware to make sure smart meters, sensors, and other devices easily connect with the stromee platform.

- Intuitive UI/UX. We created a straightforward interface as part of our IoT product design services. It encompassed effortless navigation, animated charts and tables, and a built-in educational hub.

- Web app development. We built a consumption calculator and a fast, frictionless contract creation flow.

- Mobile app development. Our mobile energy monitoring system featured consumption forecasts, contract creation and management, readings from energy monitors, cloud data sync, promo codes, and live chat support.

- Compliance. We ensured full GDPR compliance, clearly informing users how their data is collected, used, and stored.

The results of our IoT services were promising. We assisted users in reducing energy waste by up to 30% through smarter, more conscious consumption. Plus, stromee surpassed its user acquisition goals well ahead of schedule.

Aiming to use IoT for energy management effectively?

Let’s talk solutionsCommon challenges in IoT energy management projects

Rolling out an IoT power monitoring system might not be the easiest task to handle facility-wide. Several roadblocks may slow the implementation down if you’re not prepared. Let’s quickly go through each of them:

Lack of existing sensors or smart meters

Many facilities still use outdated or manual systems. Thus, there’s no easy way to collect real-time energy data. Luckily, with custom development, you can create solutions that work with your existing infrastructure. Then, phase in new IoT sensors and smart energy meters at your own pace.

Integration with legacy systems

Older SCADA, BMS, or ERP systems weren’t built with IoT for energy management in mind, leading to compatibility issues. Yet, with an API-first approach, you can develop platforms where everything finally connects.

Data overload and alert fatigue

Getting more energy data is perfect until it turns into noise. Too many alerts, too many dashboards, and not enough clarity make it harder to make the right power consumption decisions. However, handling custom development makes it possible to tailor notifications and interfaces to your workflows.

Certification and compliance challenges

Meeting standards like GDPR or ISO can complicate even simple power consumption monitor deployments, especially if you’re working in a highly regulated industry. Custom industrial IoT services, in turn, let you build with compliance in mind from day one.

Future outlook: What’s next for smart energy monitoring trends

Using IoT for energy management is only the beginning. As the tech evolves, the way we monitor and manage industrial energy is about to get even smarter — and much more powerful. Here are the top trends for smart energy monitors:

- AI for predictive load management. With artificial intelligence (AI), you can go from mere energy monitoring to energy forecasting. How? The tech analyzes historical usage patterns and predicts future demand depending on the findings. That results in better scheduling, fewer overloads, and proactive load balancing.

- Edge computing for real-time reactions. Not everything has to go to the cloud first. Edge computing lets IoT devices and sensors process data locally, right at the source. It will lead to faster responses to energy spikes, system faults, or shifting loads.

- Blockchain for energy transactions. While typically associated with cryptocurrencies, blockchain is vital in energy management in IoT. The tech serves as a secure, transparent way to track and verify energy transactions.

- Integration with carbon tracking systems. Energy consumption and carbon emissions go hand in hand. Tracking one without the other is a missed opportunity. Expect more integration between smart energy IoT applications and carbon tracking platforms, especially with tightening ESG regulations.

Conclusion

For industrial facilities, energy is more than just a utility. It’s a major cost factor. The good news? With the right tools, it’s also a prime opportunity.

IoT energy monitoring systems offer a fast path to ROI. Use them to track power use, reduce waste, and make smarter consumption decisions in real time. Connected monitoring is among your most impactful options if you strive for significant savings, sustainability, or increased efficiency.

If you’re ready to begin with IoT energy management, Yalantis provides IoT strategy consulting with scalable, tailored platforms.

Curious how IoT energy monitoring could work for you?

Let’s discuss your goalsFAQ

How much can a custom energy monitoring platform save a business?

A well-designed, IoT-enabled power usage monitor can cut electricity waste by up to 30%. How so? By studying insights into electricity consumption across the house, plant, or facility, you quickly spot inefficiencies and optimize energy spending, achieving a faster return on investment.

Can you integrate existing equipment with a smart energy monitoring system?

Of course! We specialize in integrating smart energy monitoring systems with legacy platforms and existing electricity monitors. In particular, we use APIs to connect with older SCADA, BMS, ERP systems, and your current equipment.

What devices or sensors are needed to build an IoT energy monitoring system?

To build an IoT energy management system, you typically need connected meters, current transformers, and sense-enabled sensors installed across your facility. These collect data on electricity use at the home or industrial level. They send it to a cloud computing dashboard that monitors and optimizes consumption in real time.

How long does it take to build a custom energy monitoring platform?

Project timelines vary, but building a functional power monitoring system often takes 6–12 months. Our flexible development process supports regular releases. This way, you can access core features early on.

How do you ensure data security in energy management platforms?

We design every energy monitoring system with security at its core. We ensure encryption, regulatory compliance, and full user control over personal and operational data.