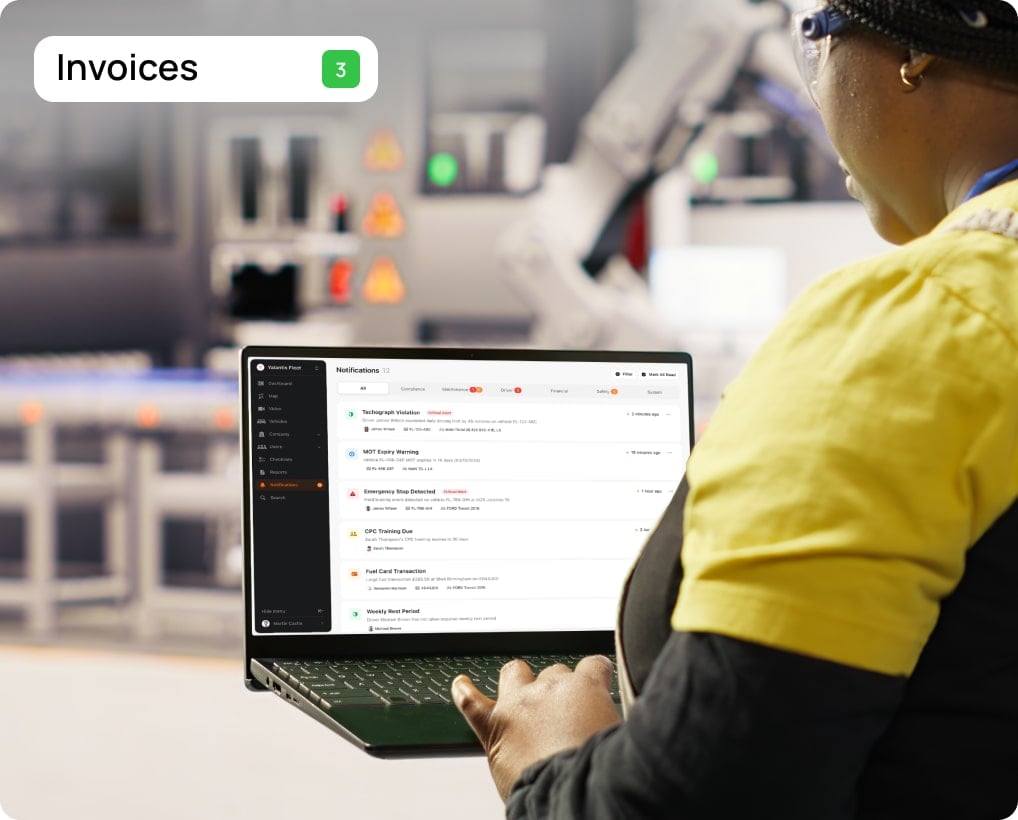

Replace an off-the-shelf fleet platform with a custom one.

AIoT Solution with Predictive Maintenance for Logistics Company Lowers Cost per Vehicle by 30%

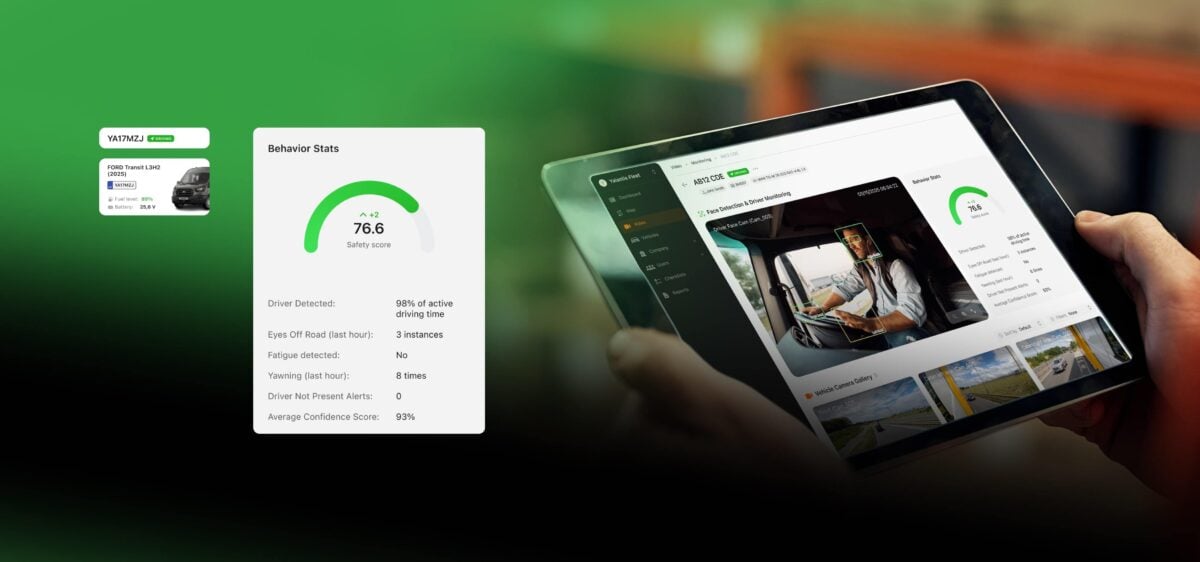

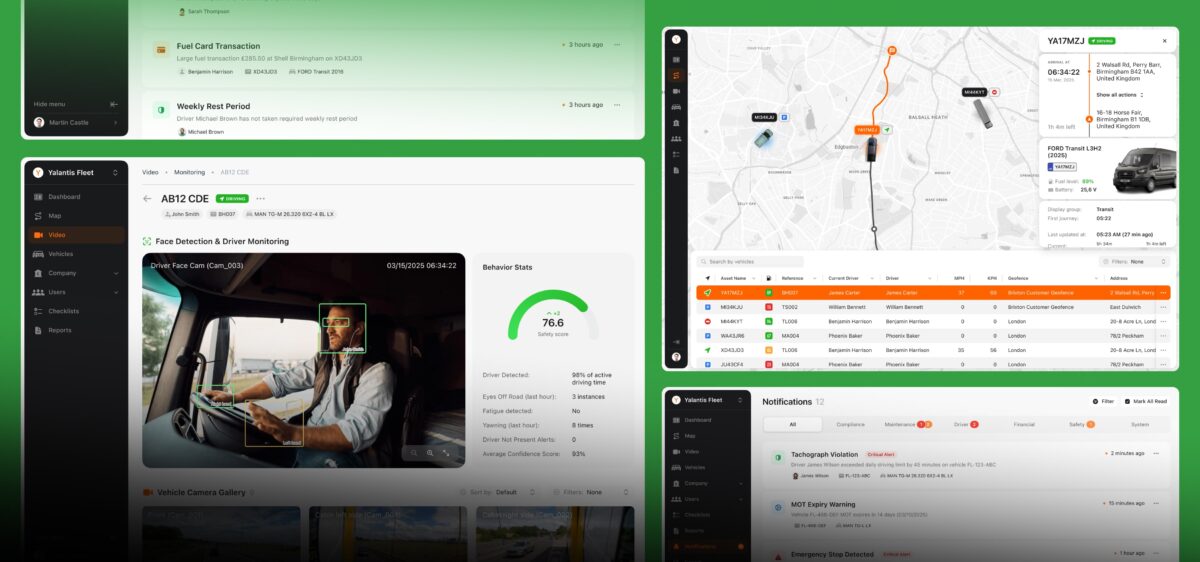

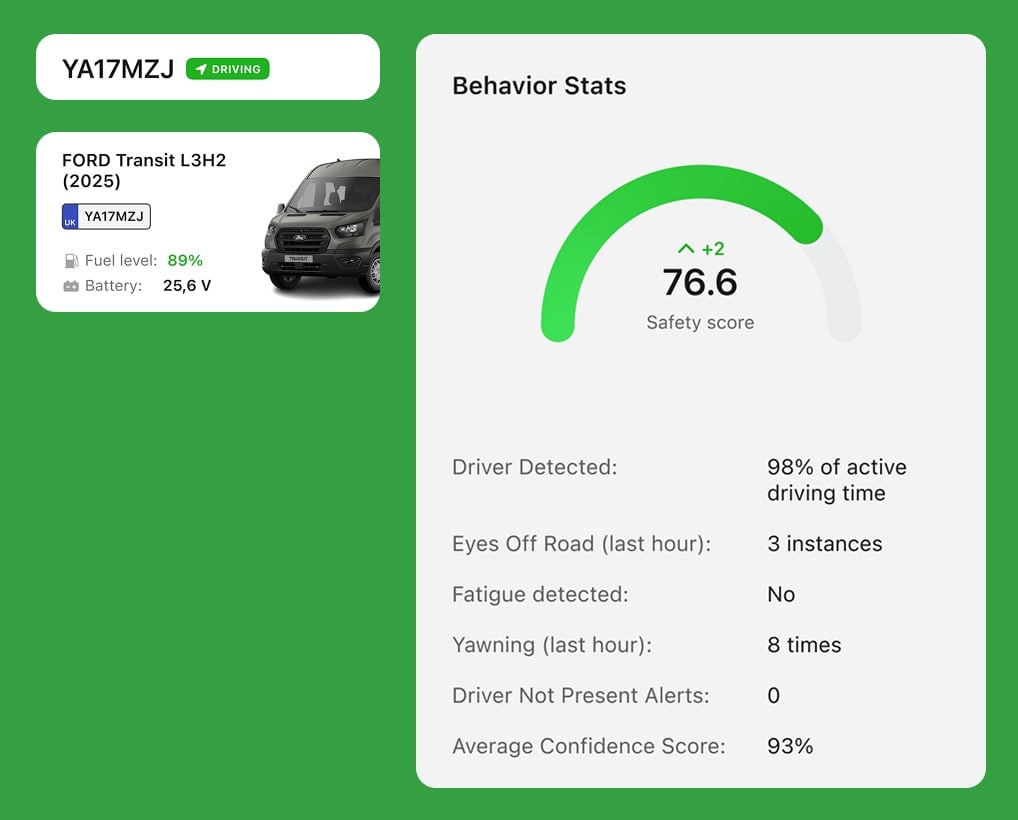

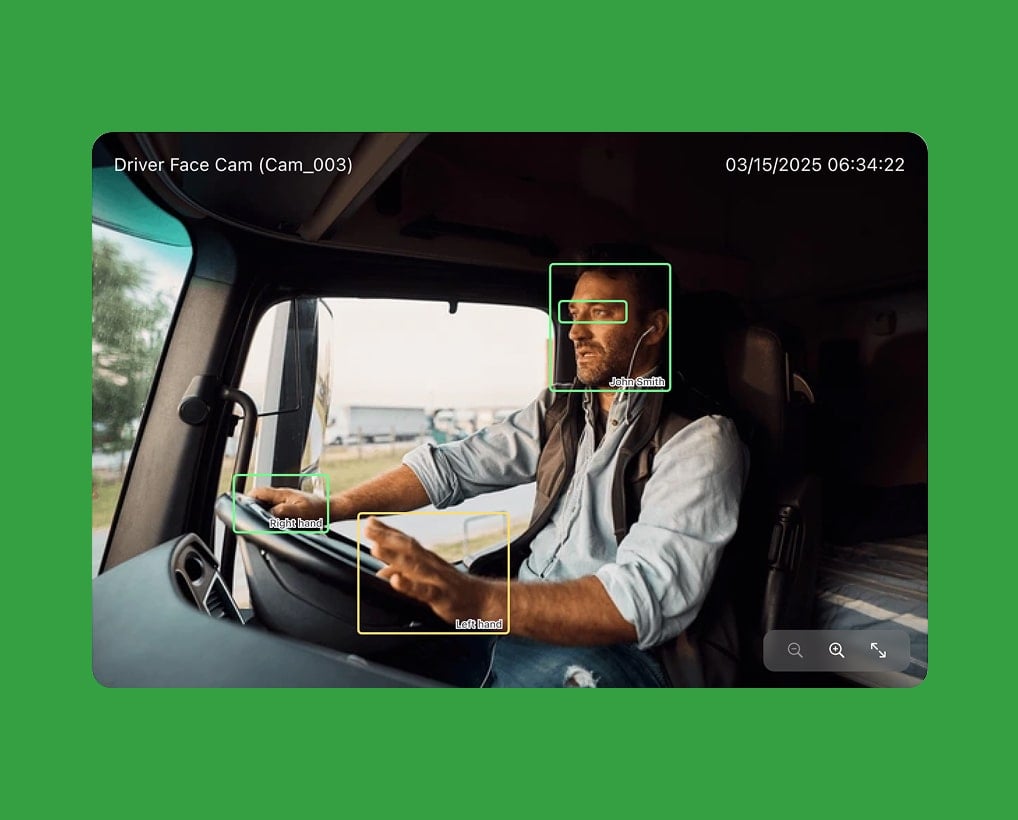

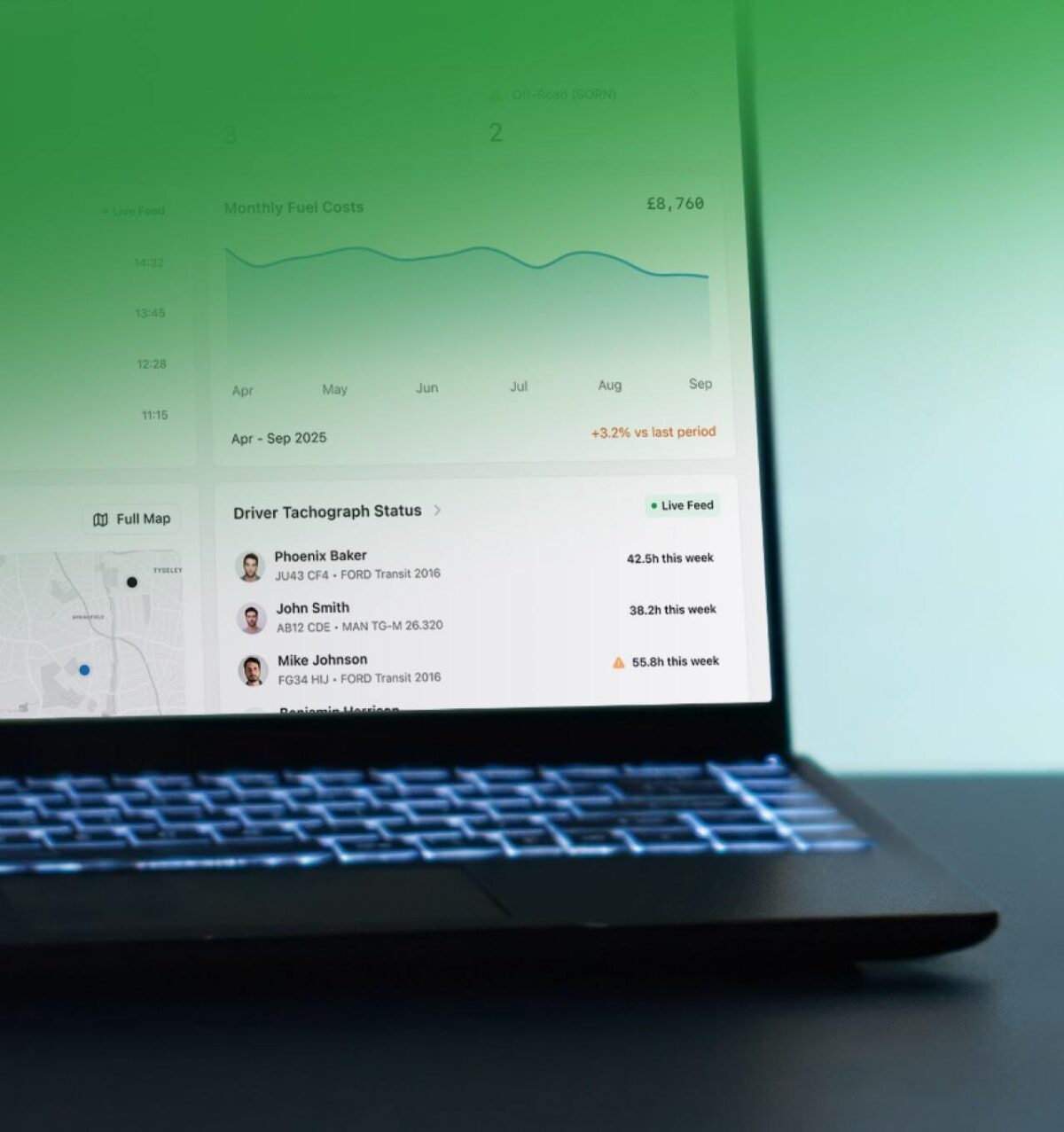

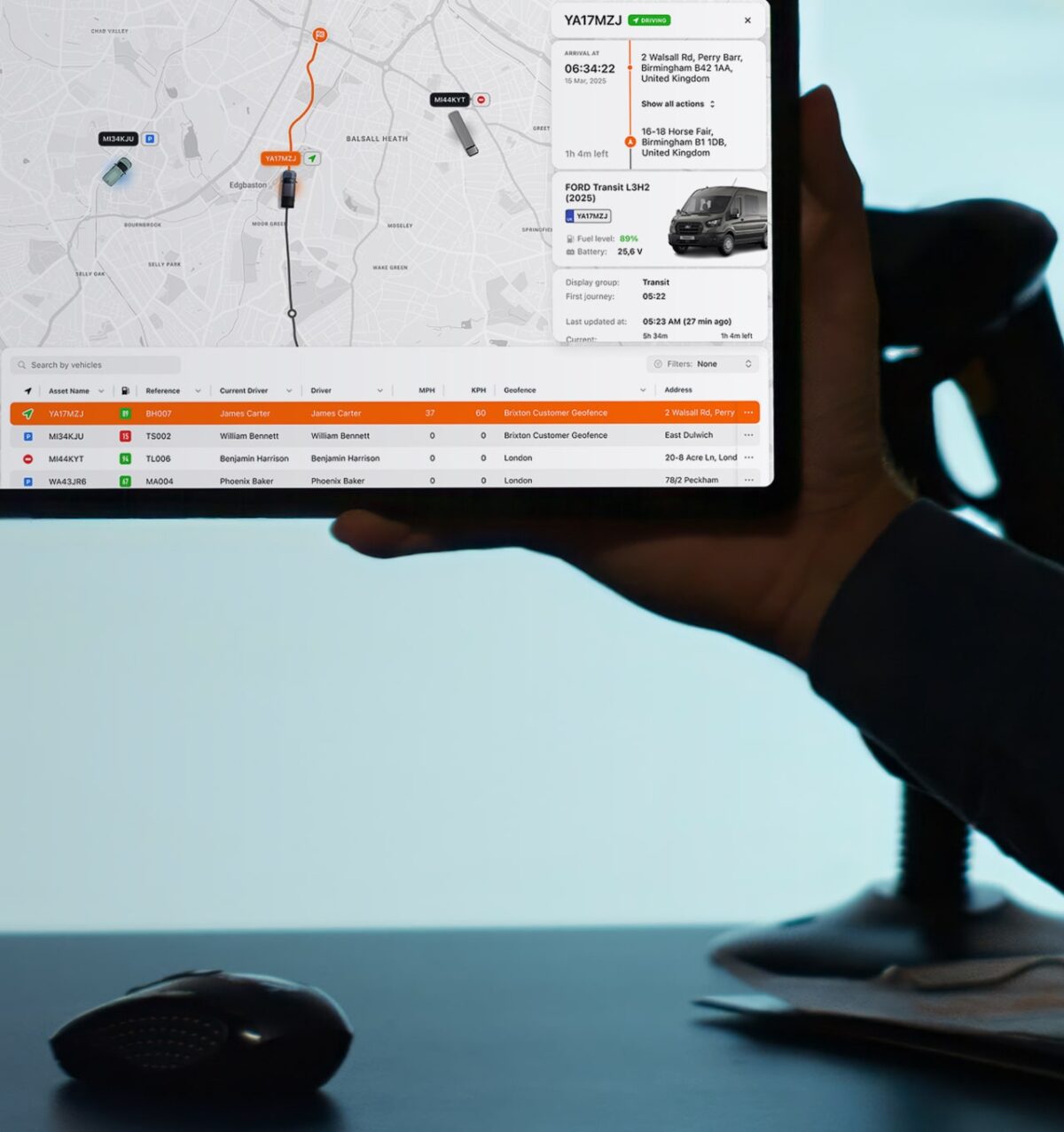

Yalantis partnered with a US-based telematics company to develop a custom IoT-based fleet management system for real-time operations, replacing an expensive third-party platform and reducing the cost per vehicle by 30%.

Cost reduction

Customer growth

System availability

“The client came to us ready to move beyond selling hardware. They wanted to offer a complete service and finally own the whole solution.”

– Mykhailo Maidan, CTO at Yalantis

Need to build an AIoT platform from scratch? Let’s make it happen.

Fulfil your success story with us. Share details about your project and book a call with us to discuss your goals.

From medical devices to industrial automation — we deliver complete enterprise solutions with regulatory compliance built-in. Everything under one roof.

Our offices

Poland

123 al. Jerozolimskie, Warsaw, 00-001

Ukraine

5 Dmytra Yavornytskoho Avenue, Dnipro, 49005

Cyprus

8 Athinon Street, Larnaca, 6023

Estonia

12 Parda, Tallinn, 10151

FAQ

-

Which levers actually produced the ~30% per-vehicle cost drop?

Eliminating the external software license, cutting map spend from ~$100K to ~$1.5K/month via an open-source mapping stack, and deploying a low-cost MDVR + custom streaming approach were the big wins. AWS cost controls and months of free credits helped too.

-

Our fleets use Teltonika and other trackers; did you normalize those protocols?

Yes. We reverse-analyzed proprietary/partially undocumented formats, built custom parsers and error handling, and brought those devices into the same real-time pipeline and UI.

-

What changed in ownership and lock-in risk once you moved off the SaaS?

The client now owns both hardware and software: a fully custom, AWS-hosted platform with no vendor lock-in, white-label flexibility for B2B customers, and a billing engine that supports multiple pricing models.

-

Where did the revenue and customer growth come from if costs went down?

Owning the platform enabled pricing control and faster feature delivery; white-labeling opened new B2B deals. The result: ~20% customer growth alongside the cost reductions.

-

What changed for the support organization post-launch?

Support requests dropped by ~50% and support costs fell 52%; issues are now handled proactively with parts-level replacements instead of whole-system swaps.

-

How quickly did you get from “go” to a usable platform?

We stood up the core platform in ~10 months, which included device integration, React web app development, Node.js/Java back-end development, and AWS infrastructure. We then iterated into AIoT features after launch.

Let’s Start from call scheduling

- Schedule a call

- We collect your requirements

- We offer a solution

- We succeed together!

Thank you for contacting us.

Meanwhile, you can explore our hottest case studies and read

client feedback on Clutch.

We are open for partnerships too

Check out our refferal program. Find out all benefits.