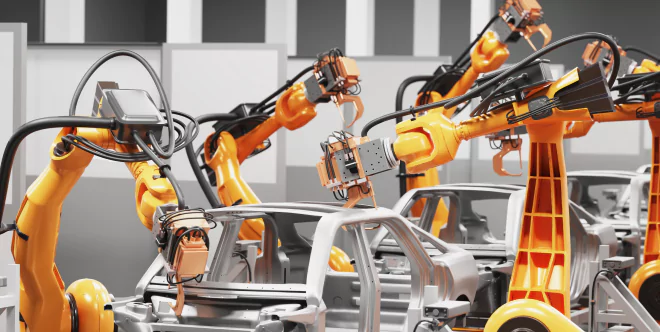

Managed IT Services for Manufacturing

Yalantis provides comprehensive IT services for manufacturing companies. From digital manufacturing consulting and custom software development to embedded hardware engineering and OT cybersecurity.

Manufacturing Challenges Our IT Solutions Address

-

Fragmented systems preventing unified operational visibility

Disconnected ERP and SCADA environments create data silos. We provide it solutions for manufacturing industry that unify these systems using ISA-95 architecture, creating a real-time “Single Pane of Glass” for your operations.

-

Legacy equipment lacking connectivity and digital intelligence

Aging factories rely on brownfield assets. Our industrial it services extract data via non-invasive gateways, enabling predictive maintenance without costly replacements or disrupting certified control logic.

-

Cybersecurity vulnerabilities exposing industrial operations

Cloud connectivity increases ransomware risks. We deliver industrial it security implementing IEC 62443 standards and EU Cyber Resilience Act compliance to safeguard your critical OT infrastructure.

-

Inability to prove compliance and sustainability

Manual reporting fails strict mandates. Our comprehensive solutions automate energy tracking, providing digital manufacturing solutions that ensure audit-ready documentation for regulatory compliance.

-

Manual processes and quality inspection bottlenecks

Paper workflows limit throughput. We deploy manufacturing it solutions, including digital technologies and manufacturing software development, to automate inspections and ensure consistent production quality.

-

Product development cycles too slow for market demands

Hardware-software integration delays launches. We provide it for manufacturing that streamlines the lifecycle. From software development services to hardware, accelerating prototyping and time-to-market.

Yalantis IT Services for Industrial Manufacturing

-

Digital Transformation in Manufacturing

Learn moreWe provide strategic digital transformation in manufacturing services that align your IT investments with operational goals. We move beyond generic consulting to design practical roadmaps that bridge the gap between legacy shop-floor realities and modern cloud ambitions.

Key Service Deliverables:

- Transformation Roadmaps

Creating phased execution plans to transform traditional manufacturing processes, prioritizing high-impact pilots before scaling to enterprise-wide deployment. - Technology Stack Assessment

Evaluating your current maturity level to recommend the right mix of manufacturing it solutions, from MES selection to cloud architecture. - ROI Modeling

Quantifying the business value of digital manufacturing solutions, ensuring every technical initiative has a clear payback period through reduced downtime or waste.

- Transformation Roadmaps

-

OT/IT Convergence & Data Engineering

A foundational service that unifies fragmented manufacturing data into a “Single Pane of Glass,” aligning your architecture with ISA-95 standards to ensure seamless data flow between the shop floor (Level 0-2) and enterprise systems (Level 4).

Key Service Deliverables:

- Unified Namespace (UNS) Architecture

Implementing event-driven architectures (MQTT/Sparkplug B) that decouple devices from applications, creating a single source of truth for all production data. - Data Lake Construction

Building scalable storage solutions (InfluxDB, TimescaleDB, AWS SiteWise) to consolidate high-frequency sensor telemetry with ERP context for long-term trend analysis. - Protocol Normalization

Deploying drivers to translate “Protocol Zoo” languages (Modbus, Profinet, OPC UA) into a standardized format for cloud or on-prem ingestion. - OT Data Governance

Establishing role-based access control and data lineage tracking to ensure data security compliance with internal standards and external regulations.

- Unified Namespace (UNS) Architecture

-

Legacy System Modernization Services

We address your №1 pain: keeping aging machinery operational and connected without expensive controller replacements. We provide specialized industrial it services for non-invasive modernization in brownfield environments.

Key Service Deliverables:

- Legacy P2V (Physical-to-Virtual) Migration

Virtualizing legacy industrial PCs (Windows XP/7) to run on modern server hardware, eliminating hardware dependency risks while preserving original HMI logic. - Code Refactoring

Reverse-engineering and refactoring undocumented legacy code to extend the life of critical production assets. - HMI Modernization

Replacing obsolete operator interfaces with modern, web-based HMIs that improve usability and remote visibility. - Brownfield Connectivity

Extracting data from “dumb” assets using minimally invasive techniques that do not disrupt certified control loops.

- Legacy P2V (Physical-to-Virtual) Migration

-

Industrial Hardware Design & Prototyping

Unlike pure software agencies, we are a strategic engineering partner capable of building the physical device. Our Warsaw lab covers the full lifecycle from Industrial PCB Design to mechanical enclosure design.

Key Service Deliverables:

- Custom Electronics

Circuit board design optimized for signal integrity, power efficiency, and industrial temperature ranges. - Ruggedized Enclosure Design

Mechanical engineering for devices requiring IP67 ratings or operation in high-vibration environments. - ATEX Compliant Hardware

Designing intrinsically safe hardware for hazardous environments where explosion risks exist. - Rapid Prototyping

Fast-tracking hardware concepts into functional prototypes for field testing before mass production.

- Custom Electronics

-

Secure Edge Engineering on Rust

We build memory-safe, crash-resistant firmware that future-proofs your machinery against the upcoming EU Cyber Resilience Act (CRA) by replacing legacy C++ components with secure Rust implementations.

Key Service Deliverables:

- Non-invasive “Sidecar” Gateways

Developing connectivity modules that sit alongside your main controller to handle cloud communication, ensuring you can add IoT features without voiding warranties. - Rust for Embedded Systems

Utilizing Rust to eliminate buffer overflows and memory corruption vulnerabilities, the leading cause of security breaches in connected devices. - Secure OTA Firmware Updates

Implementing cryptographically signed update pipelines to manage fleet software remotely without “bricking” devices. - Edge Analytics

Running logic at the edge to reduce cloud bandwidth costs and enable real-time local decision-making.

- Non-invasive “Sidecar” Gateways

-

Custom Manufacturing Software Development

We offer comprehensive manufacturing software development services that control production execution and automate quality assurance. We build the “brains” of your factory, driving operational efficiency through custom digital tools.

Key Service Deliverables:

- Custom MES Modules

Building tailored Manufacturing Execution System components to track WIP, manage recipes, and digitize paper-based workflows. - Computer Vision for Quality Control

Implementing automated optical inspection (AOI) systems to detect defects in real-time on high-speed lines. - Digital Twin Development

Creating virtual replicas of physical assets to simulate process changes and optimize production parameters before implementation. - Workflow Automation

Integrating disparate systems to automate manual data entry and reporting tasks.

- Custom MES Modules

-

Industrial Connectivity & IoT

Learn moreWe engineer the connectivity layer that bridges your machines to the cloud, providing the robust infrastructure needed to securely transport data from the shop floor to enterprise systems.

Key Service Deliverables:

- Cloud-Agnostic IIoT Architecture

Designing resilient, scalable platforms on AWS IoT Core, Azure IoT Hub, or Google Cloud that avoid vendor lock-in and align with your existing IT ecosystem. - Secure Edge Connectivity

Deploying gateways to bridge OT protocols (Modbus, OPC UA) with cloud standards (MQTT/Sparkplug B), ensuring encrypted and reliable data transmission. - Real-Time Telemetry Pipelines

Building stream processing workflows that ingest high-frequency sensor data for immediate visualization, condition monitoring, and anomaly detection. - Device Fleet Management

Implementing centralized tools for the remote provisioning, health monitoring, and security patching of thousands of connected industrial assets.

- Cloud-Agnostic IIoT Architecture

-

“Lift and Shift” Modernization

A strategic migration service that relocates on-premise industrial applications (legacy SCADA, MES, and historian databases) to secure cloud or hybrid edge infrastructure with minimal refactoring.

Key Service Deliverables:

- Legacy P2V (Physical-to-Virtual) Migration

Encapsulating aging control systems (running on obsolete Windows XP/7 hardware) into secure, portable virtual machines or containers. This eliminates hardware dependency risks while preserving the original, certified operator interfaces and logic. - Hybrid Cloud Infrastructure Design

Architecting low-latency environments where critical real-time control remains at the edge, while heavy compute workloads (reporting, analytics, long-term storage) are shifted to AWS, Azure, or private clouds. Ensuring production continuity even during internet outages. - Security Hardening & Air-Gap Simulation

Wrapping migrated legacy applications in modern security layers, including micro-segmentation, identity-aware proxies, and encrypted tunnels, to protect vulnerable protocols that were never designed for connected networks. - Automated Disaster Recovery (DR) Pipelines

Replacing manual tape/disk backups with automated, cloud-based snapshotting and failover orchestration. This ensures rapid restoration of plant-floor systems in minutes rather than days in the event of ransomware or corruption.

- Legacy P2V (Physical-to-Virtual) Migration

Core Technology Solutions for Industrial Manufacturing

Predictive Maintenance

Beyond monitoring, we use Predictive Maintenance to analyze vibration and telemetry, forecasting failures before they halt production.

Digital Twins in Manufacturing

We build Digital Twins to mirror assets, allowing you to run simulations, test firmware, and optimize workflows without risking physical equipment.

Benefits of Manufacturing IT Services with Yalantis

-

Integrate Legacy & Modern Systems Without Rip-and-Replace

Bridge brownfield equipment with digital manufacturing solutions to preserve capital investments. We extract data via non-invasive gateways without touching certified logic, delivering cost-effective industrial it solutions for seamless modernization.

-

Reduce Operational Costs Through Data-Driven Optimization

Eliminate inefficiencies by unifying production data. Our manufacturing it solutions identify energy savings and reduce unplanned downtime through predictive analytics, optimizing costs with data-driven smart manufacturing.

-

Achieve Cybersecurity Compliance & Protect Infrastructure

Meet EU Cyber Resilience Act and IEC 62443 mandates while shielding operations. We provide robust industrial it security through network segmentation and secure access to protect critical OT assets.

-

Accelerate Product Development with End-to-End Engineering

Speed time-to-market by synchronizing hardware and manufacturing software development. Our engineering approach ensures early integration testing to avoid costly redesigns, improving production efficiency.

-

Scale Solutions Across Global Manufacturing Operations

Deploy standardized platforms supporting multi-site aggregation. We provide scalable it solutions for industrial manufacturing that ensure corporate visibility and local control through centralized data management and production processes.

-

Build Internal Capabilities Through Knowledge Transfer

Reduce vendor dependency via structured training. Ourindustrial it services focus on upskilling your teams, building lasting internal expertise in it for manufacturing, IIoT, and OT security.

Testimonials from our clients

IIoT Solutions Insights

How IoT is transforming the manufacturing industry

Discover how IoT in manufacturing makes processes more efficient and cost-effective through predictive maintenance, quality control, and inventory management.

How can IoT suppliers build industrial IoT software to attract new customers?

Learn the specifics of industrial IoT development to cover IoT vendors’ and their customers’ needs related to large-scale industrial IoT monitoring.

IIoT Data Management and Analytics for Manufacturers

Large manufacturers are gradually jumping to a data-driven operational strategy and utilizing IIoT devices. See how the industry wins by adopting industrial IoT data management.

FAQ

Can Yalantis integrate IT solutions with existing manufacturing systems?

Yes, integration with legacy ERP, MES, SCADA, and PLCs is our core expertise. We build custom middleware, API adapters, and protocol translators that connect brownfield equipment and proprietary systems on the factory floor, regardless of vendor or age. Our integration approach preserves existing workflows while enabling the adoption of modern digital technologies, avoiding the disruption and cost of system replacements.

What industries and manufacturing segments do you specialize in?

We’ve delivered digital manufacturing initiatives across automotive (Tier 1/2 suppliers), pharmaceuticals (FDA-regulated environments), food and beverage (HACCP compliance), discrete electronics (high-mix assembly), process chemicals, and industrial machinery OEMs. Our expertise extends to supply chain management optimizations, adapting to new segments through industry research, domain expert collaboration, and proven software engineering methodologies.

How do you ensure security and compliance in manufacturing IT systems?

Every project deploying advanced technologies includes security by design: threat modeling, network segmentation separating OT from IT, encrypted communications, role-based access controls, and penetration testing. For compliance (GDPR, FDA 21 CFR Part 11, IEC 62443), we implement audit trails, data integrity controls, validated documentation, and change management procedures that satisfy regulatory inspections and certification requirements

Do you provide custom IT solutions or ready-made manufacturing platforms?

We specialize in building the ideal industrial manufacturing solution for operations where off-the-shelf platforms cannot address unique workflows, regulatory requirements, or the complexity of IoT in manufacturing. For standard needs, we recommend and integrate proven third-party MES or IIoT platforms. Our value is bridging gaps between commercial products and operational reality through bespoke engineering.

How long does it take to implement IT services for manufacturers?

Timelines vary by scope: connectivity pilots demonstrate feasibility in 8-12 weeks, custom software development projects typically run 4-9 months, and comprehensive digital transformation in industrial manufacturing programs span 12-36 months across multiple phases. We structure engagements to deliver incremental value—proving ROI with quick-win pilots before committing to larger investments.

Can manufacturing IT solutions scale as production grows or expands to new sites?

Yes, scalability is an architectural priority. We design cloud infrastructure using auto-scaling containers and serverless computing that handles 10x traffic spikes, ensuring stability for every production line without manual intervention. Data platforms support sharding and replication for multi-site deployments. Edge solutions use standardized templates that accelerate new facility rollouts while accommodating site-specific equipment variations and local regulatory requirements.

How do your solutions impact overall business performance?

Our strategies directly improve productivity by automating manual tasks, reducing waste, and optimizing throughput. By leveraging these tailored digital technologies, manufacturers gain a sustainable competitive edge, ensuring their operations are agile, data-driven, and ready for future market demands.

Contact us

got it!

Keep an eye on your inbox. We’ll be in touch shortly

Meanwhile, you can explore our hottest case studies and read

client feedback on Clutch.

Nick Orlov

IoT advisor

How to get started with IoT development

-

Get on a call with our Internet of Things product design experts.

-

Tell us about your current challenges and ideas.

-

We’ll prepare a detailed estimate and a business offer.

-

If everything works for you, we start achieving your goals!