To build a real-time fleet tracking system, you need to mix your tracking requirements with GPS and IoT sensors, cloud infrastructure, geofencing, telematics, and an intuitive dashboard. Alternatively, you can opt for a ready-made solution.

What is GPS fleet tracking system in the first place? It’s a tech that combines GPS, IoT, connectivity, and cloud software to monitor fleet activity in real time. If that’s what you’re planning to build, this post covers everything from key features to architecture, protocols, and tech stack choices.

Recommended for:

- tech leads at logistics, transportation, or delivery companies

- fleet operators looking to move beyond out-of-the-box fleet tracking software

- product owners developing TMS or SaaS fleet management systems

- IoT consultants and system architects working on real-time vehicle tracking solutions

And we’re not just talking theory. When providing IoT for logistics, we’ve helped cut delivery time by 1.5× for one client and connect 180+ trucks to a real-time dashboard for another. See what’s possible and how in our guide.

Highlights:

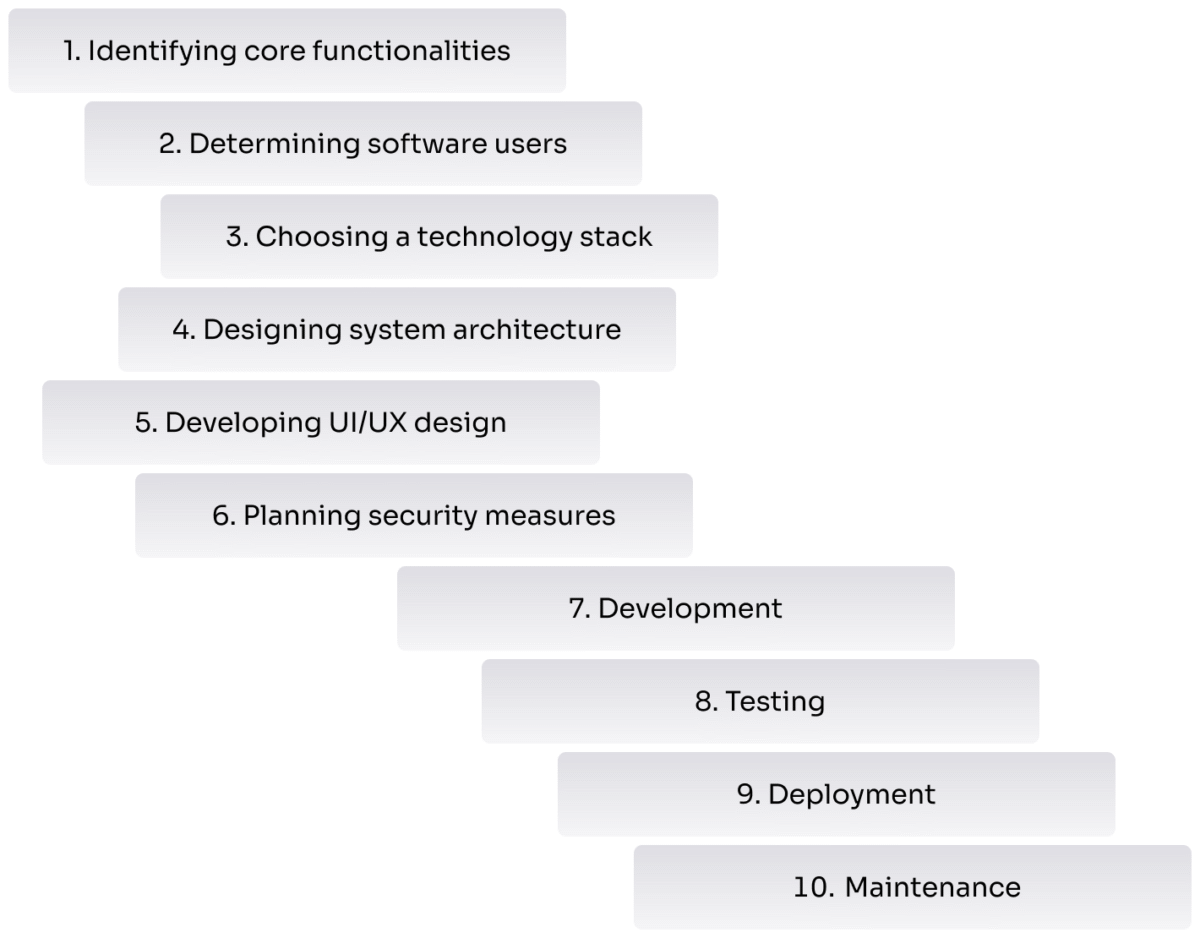

- follow the ten-step fleet tracking development blueprint: decide on the features, user roles, and tech stack, work on architecture, UI/UX, and security, and then develop, test, deploy, and maintain.

- consider the must-have features, from real-time GPS tracking, routing, and dispatching for fleet managers to a mobile app for fleet tracking and incident reporting for drivers

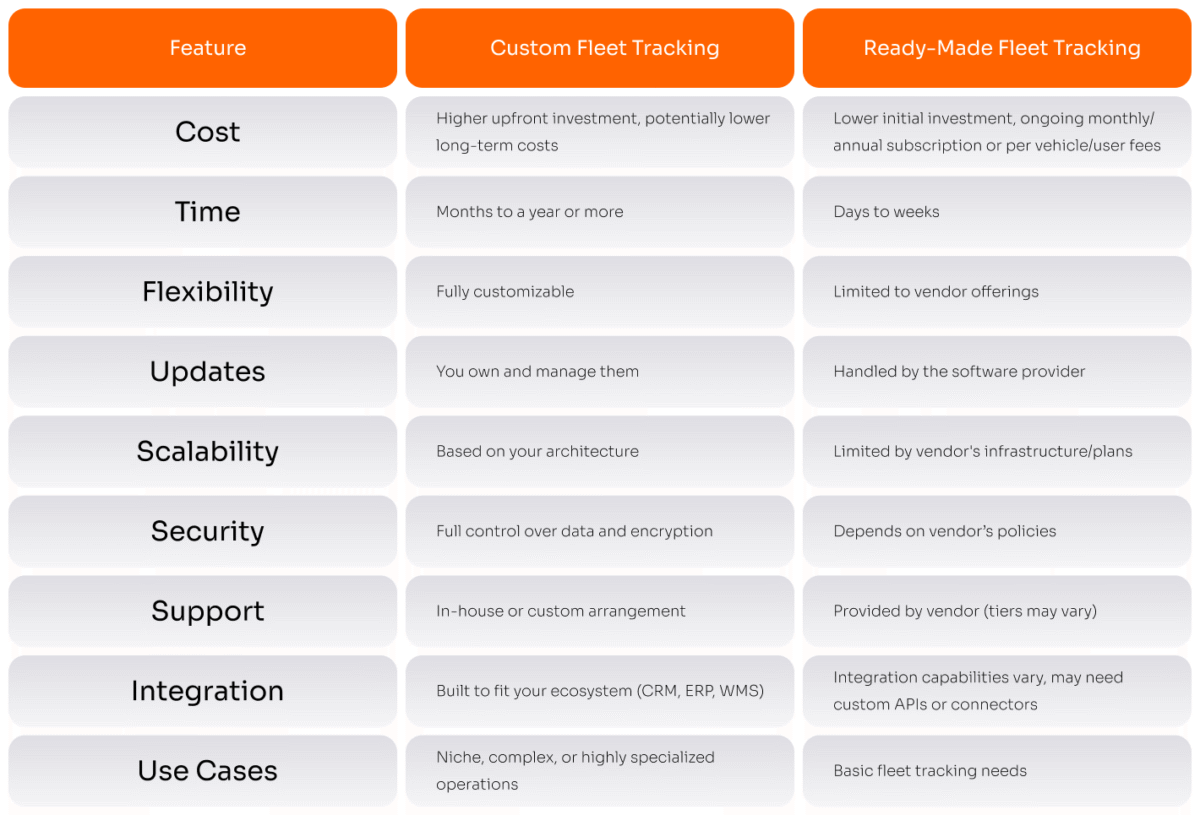

- mind that the decision between custom and ready-made is often a tradeoff: flexibility and control vs. speed and convenience

What Does It Take to Build a Real-Time Fleet Tracking System?

It takes several steps: identifying what your system must do, who will use it, and how it will be built, secured, tested, and maintained. Here’s a more detailed breakdown:

10 Steps to Develop a Fleet Tracking System

Developing a real-time fleet tracking platform means gradually moving through the following stages:

- Defining must-have features. What purpose should your system serve? Decide on the absolute essentials, whether a live GPS fleet map or geofencing for fleet vehicles. If you’re unsure, build an MVP to test what works.

- Determining users. Identify your fleet monitoring system’s users: dispatchers, fleet managers, drivers, maintenance staff, end customers, or a combination of them. Keep in mind that each role needs different data and tools.

- Picking the tech stack. Select backend and frontend frameworks, databases, and protocols (e.g., MQTT fleet communication) that support real-time updates and heavy data flows.

- Designing system architecture. Determine the system’s fleet tracking architecture, whether microservices or monolithic. Work on the data flows, the design of REST API for fleet systems, and the strategies for scalability.

- Designing UI/UX. Create a dashboard with the end user in mind to improve adoption. Consider mobile-first for teams on the go.

- Building in security. Secure your fleet tracking solutions with authentication (e.g., OAuth2), authorization, encryption (e.g., TLS, AES), and regulatory compliance.

- Developing the system. Build the backend, frontend, and APIs. Handle device firmware services and embedded software development as well. Split the work into sprints and create core modules first, for example, GPS fleet tracking and vehicle syncing.

- Testing. Use test rigs to simulate GPS data, network outages, and stress loads. Cover everything: unit tests for separate features, integration tests across services, and end-to-end tests mimicking full user journeys.

- Deploying. Use CI/CD pipelines to automate build, test, and release cycles. Launch the system.

- Maintaining, monitoring, improving. After the rollout, keep your system healthy. Monitor for issues, patch security holes, and introduce updates based on user feedback.

Should You Build Custom or Use Ready-Made Fleet Tracking Software?

Following all ten steps gives you total control. But it also requires significant time, budget, and expertise. Many businesses compare that to the faster, lower-friction alternative: pre-built GPS fleet tracking solutions.

Key Terms in Fleet Tracking You Should Know

Before we proceed with explaining how to build fleet tracking systems, let’s clarify some terms we’ve mentioned earlier.

- Telematics. A combination of telecommunications and informatics that enables the monitoring of vehicles through GPS technology and on-board diagnostics, often using Teltonika devices we’ve implemented in lots of projects.

- Real-time GPS location sharing. The process of continuous sharing of a vehicle’s exact geographical coordinates using the Global Positioning System.

- Geofencing. A virtual perimeter you draw on a map. When vehicles enter or exit, the system triggers alerts or actions (e.g., notify dispatch).

Must-Have Features of a Real-Time Fleet Tracking System

A real-time fleet tracking system typically offers features for fleet managers, drivers, and overall business processes. Let’s get all these categories straight.

For Fleet Managers and Dispatchers

These help manage fleet operations by monitoring vehicles and workers.

- Live GPS tracking. Allows you to pinpoint vehicle location, speed, and status in real time. Using telematics here is even more beneficial — from 15 to 20% in cost savings, as stated in the Fleet LatAm Conference 2021.

- Dispatching. Lets you choose the most suitable vehicle and driver for a job based on availability, location, and urgency.

- Fleet route optimization. Allows you to lay the most efficient route depending on traffic, weather, and road restrictions.

- Route scheduling. Set shift plans, delivery windows, or maintenance slots with calendar-based tools.

- Fuel monitoring. Industrial fleet tracking is simply impossible without managing fuel consumption. This feature, combined with IoT, helps measure fuel levels automatically.

- Maintenance and diagnostics. What is fleet management system without proper maintenance mechanisms? Just a breakdown waiting to happen. These features allow you to identify issues based on engine diagnostics, mileage thresholds, or inspection reports.

- Task management. With this feature, you can assign and track vehicle-related tasks, such as repairs, deliveries, and inspections.

- Data security and compliance. Protects all data, from driver logs to GPS histories, with encryption, access controls, and compliance with GDPR, CCPA, PIPEDA, and other regulations.

For Drivers

These features improve driver safety and productivity.

- Mobile dashboard. An app or in-vehicle display showing assigned routes, schedules, messages from dispatch, and navigation.

- GPS route history. Logs every trip to subsequently analyze driver behavior, including speeding, harsh braking, or idling.

- Incident reporting. Allows for reporting of accidents or near-misses right from the vehicle.

- Inspections. A driver logs issues (e.g., tire pressure, brakes), which triggers automatic maintenance requests.

- Notifications. Enables sending updates to drivers about reroutes, new assignments, or delivery changes.

For Operational Efficiency

Beyond the road, fleet monitoring systems should work for your broader operations.

- VIN lookup and asset records. These let you identify and catalog vehicles for tracking lifecycle, warranty, or resale data.

- Inventory and parts management. Allows for monitoring spare parts and reorder thresholds.

- Analytics and custom reporting. Enables studying various metrics and reporting on the outcomes.

What Tech Stack & Protocols to Use for a Fleet Tracking Solution?

To build a real-time fleet management tracking system, you need a mix of frontend, backend, database, and asset tracking software technologies. Let’s see what your stack might look like.

Frontend and Backend Technologies

For the frontend, use React, Vue.js, or Angular as these support component reuse, fast rendering, and real-time data updates. Choose Node.js, Django, or Ruby on Rails for the backend because they can handle complex business logic effectively.

Databases and Storage

Here, you’ve got plenty of options depending on your needs. Choose from PostgreSQL, MongoDB, AWS, Google Cloud Storage, Redis, and Apache Kafka.

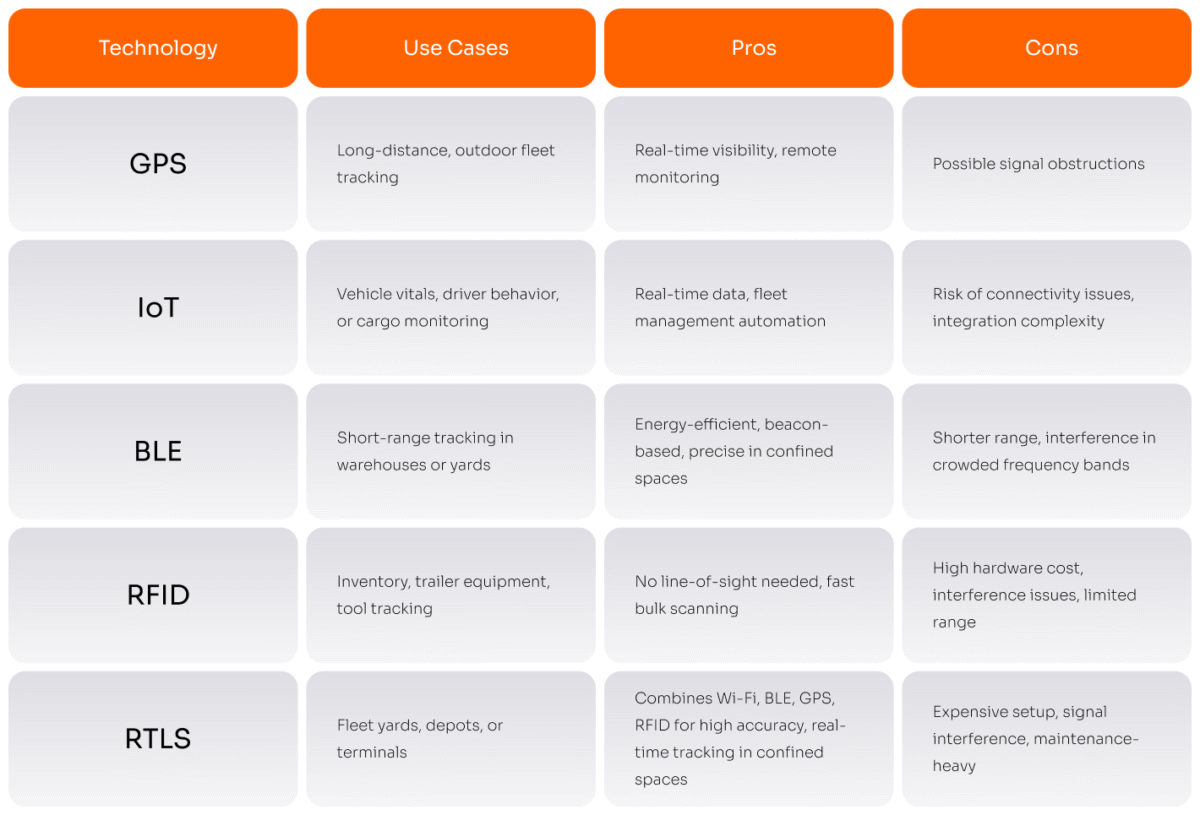

Asset Tracking Technologies

When working on fleet management tracking software, you may be choosing between GPS, RFID, IoT, and other tracking technologies. Here’s a breakdown of the most common ones:

Communication Protocols

To transmit vehicle sensor data to the cloud (and back), your GPS fleet management system has to use communication protocols. The most widely used include MQTT, WebSockets, HTTPS/REST, and CoAP.

What Are the Common Challenges in Custom Fleet Tracking Development?

Dealing with large volumes of data, ensuring security, integrating with existing systems, and addressing connectivity gaps are just some of the challenges you’ll likely encounter when building a fleet management software system. Let’s discuss these and other hurdles in greater detail:

Handling High-Volume, High-Velocity Data

When you track hundreds of vehicles, you’re dealing with constant streams of GPS, sensor, and status data. Therefore, you need a robust infrastructure to process and store this data.

Ensuring Security and Compliance

Driver locations, vehicle diagnostics, incident logs, and any other critical info must be thoroughly protected. Yet, securing every layer of the telematics fleet tracking solution may be complex.

Integrating with Existing Systems

The best fleet tracking software must connect with your current tools (CRM, ERP, TMS, WMS, and so on) easily. But the integration may be tricky due to different formats, protocols, or APIs.

Dealing with Connectivity Issues

Real-time location tracking assumes constant connectivity. However, fleets often travel through cellular dead zones, tunnels, or remote areas. Maintaining data continuity and accuracy in such circumstances is another hurdle.

Scaling Infrastructure

As your fleet grows, so do the demands on your system. Making sure it scales without performance drops and lags is one more challenge you’ll have to solve.

How Yalantis Built a Custom IoT-Based Fleet Tracking Platform

This case study shows how IoT-powered predictive analytics and process automation increased order delivery speed by 1.5× and cut operating costs by up to 40% for a logistics company managing a 350+ vehicle fleet.

Key implementation steps included:

- Embedding IoT in vehicles and assets. We chose sensors that track geolocation, tire pressure, speed, load, and more.

- Designing the architecture. Yalantis used a microservices approach based on AWS.

- Automating data flows with ETL pipelines. We implemented ETL processes and ensured uninterrupted real-time data streaming with eSIMs.

- Enabling predictive vehicle maintenance. We combined ML algorithms, BI tools, and AWS IoT development services so that the system could predict mechanical issues before they happened.

- Building multi-role interfaces. The Yalantis team designed separate interfaces for managers, drivers, clients, and web support specialists.

“The benefits of fleet tracking system we delivered? 50% greater operational efficiency, with nearly 90% of internal processes fully digitalized.”

Conclusion

Building a real-time fleet tracking app from scratch might seem like a significant, resource-heavy task. But knowing the essentials makes it entirely doable:

- ten steps, from defining features to design, development, and deployment

- must-have features for fleet managers, drivers, and operations

- tech stack and communication protocols

- common challenges to stay away from

Whether you’re modernizing a delivery fleet or launching a brand-new tracking solution, the fundamentals above set you on the right path. And with a reliable fleet tracking software development company, your system can go beyond live maps.

Need a logistics tracking solution?

FAQ

How much does it cost to develop a fleet tracking platform?

To develop a simple fleet tracking solution, you’ll need from $7,000 to $35,000. However, the cost of fleet tracking systems of higher complexity (for example, those that include edge computing in IoT, fuel management system for fleets, or a vehicle telematics system) starts at $50,000 and beyond.

Can we build on top of open-source GPS tracking platforms?

Absolutely. You can start with an open-source GPS tracking app for fleets, subsequently customizing it to your needs. This is the best kind of GPS fleet tracking for small businesses.

Do you offer firmware or embedded support for telematics devices?

Yes, we do support firmware and embedded software development for telematics devices. Whether you’re building a custom IoT for fleet tracking setup or enhancing an existing GPS device integration, we’ve got your back.

Can you support multi-vehicle, multi-country deployment?

Of course. We offer cloud-based fleet management system GPS tracking for various vehicles across different regions. We cover everything from localization to regulatory compliance, making the GPS tracking system for vehicles work across borders.