Several years ago, a severe snowstorm blocked shipments to over 100 Chicago COVID-19 vaccine sites, forcing widespread appointment cancellations as city officials promised all missed vaccines would be rescheduled quickly and no doses would spoil. Despite the delay, the public health commissioner assured that proper storage kept doses safe.

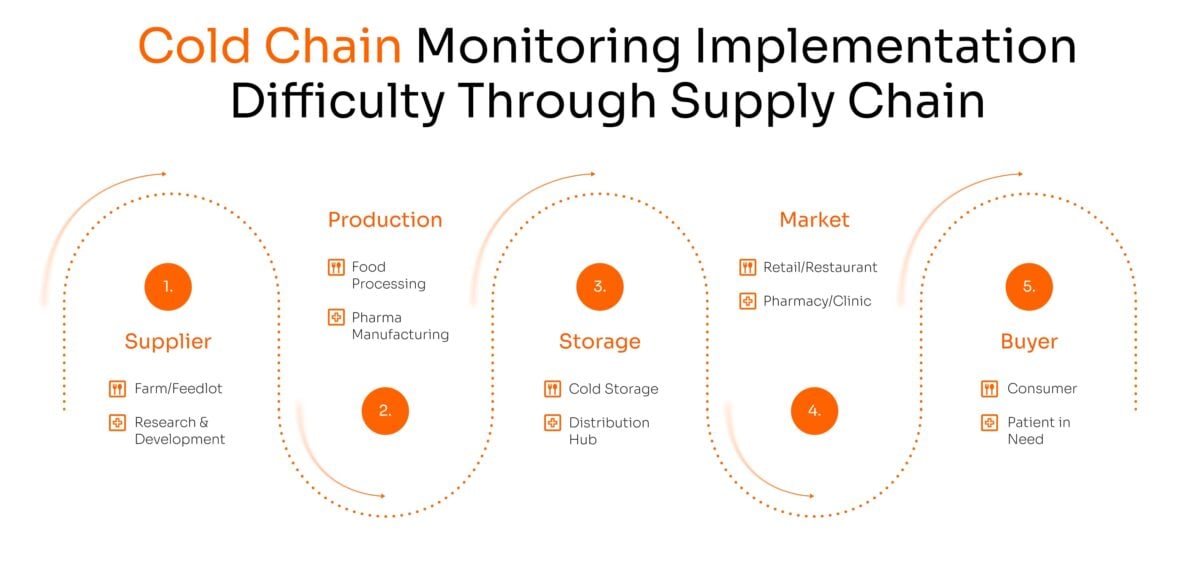

This scenario explains why cold chain IoT monitoring has become mission-critical. Failed cold chain management triggers regulatory investigations, public health crises, and lost contracts when products arrive compromised despite expensive tracking systems. In extreme cases, the cost is measured in human lives lost.

Most organizations discover the hard truth after their first deployment fails: building effective cold chain IoT solutions requires navigating technical obstacles that can consume budgets and derail timelines. Connectivity vanishes on rural highways. Regulatory frameworks contradict each other across borders. Legacy systems refuse to integrate. These aren’t minor implementation details – they’re project killers that demand specialized expertise to survive.

Smart cold chain IoT solutions transform supply chain blind spots into actionable intelligence. Effective cold chain monitoring systems create early warning capabilities while maintaining the documentation trail required for cold chain compliance.

Organizations that benefit most from this approach:

- Handle products where temperature deviation equals total loss (not just quality issues)

- Operate under tight regulatory scrutiny requiring bulletproof cold chain compliance

- Manage sprawling cold storage supply chain networks with multiple facilities and carriers

- Need seamless integration of IoT in cold chain management with existing ERP, WMS, and logistics platforms

The technical challenge goes deeper than simple cold chain temperature monitoring. You need bulletproof systems that keep working across cellular dead zones, unreliable warehouse WiFi, and international shipping routes while maintaining pharmaceutical-grade accuracy for perishable goods temperature monitoring. The business challenge is proving ROI when prevention costs are obvious, but prevented disasters remain invisible.

Nobody tells you upfront that 60% of cold chain IoT implementations fail to deliver expected results. The technology works fine in controlled environments. The problems emerge when refrigerated trucks hit cellular blackouts in Montana, when FDA auditors demand documentation that doesn’t exist, or when your ERP system can’t parse sensor data formats.

In this article, you’ll learn:

- What are the core components of IoT cold chain monitoring systems

- How to ensure compliance with FDA and EU regulatory standards

- How to implement cold chain IoT solutions in existing workflows

- How to calculate ROI and measure business impact

- How to evaluate vendors and select the right solution

- Where implementations typically break down and how to avoid these pitfalls

How Does Cold Chain IoT Monitoring Protect Perishables in Transit?

Temperature-sensitive products represent $270 billion in global trade, yet traditional monitoring methods create dangerous gaps that leave perishables vulnerable. The pharmaceutical industry faces severe consequences, with the biopharma sector losing approximately $35 billion annually due to temperature-controlled logistics failures.

Traditional approaches fail in three critical ways: manual temperature checks miss excursions between readings, basic cold chain data logger IoT devices require physical retrieval to discover problems after damage occurs, and even connected sensors fail when networks crash or batteries die during critical moments.

Moreover, most legacy systems lack contextual awareness, meaning they can’t differentiate between minor acceptable deviations and critical failure conditions. This often results in false positives or complete failure to alert, eroding trust in the system.

Cold chain IoT monitoring transforms these vulnerabilities into protection mechanisms that safeguard perishable goods throughout their journey.

What is Cold Chain IoT Monitoring?

A cold chain monitoring system combines wireless sensors, connectivity infrastructure, and analytics software to track environmental conditions affecting perishable goods. Unlike traditional data loggers, IoT solutions transmit real-time data to centralized platforms for continuous monitoring, instant alerts, and automated compliance reporting.

But designing these systems requires compromise. Sensors must be accurate, durable, low-power, and cheap enough to scale. Every connectivity method has trade-offs — LoRaWAN wins on battery life but fails without dense infrastructure; cellular works anywhere with a tower but drains batteries fast; satellite adds global coverage at a premium cost.

Core Environmental Sensors:

- Temperature sensors with ±0.1°C accuracy for pharmaceutical applications

- Humidity sensors measuring 0-100% RH with ±2% precision

- Shock and vibration detectors for handling quality assessment

- Door/light sensors indicating unauthorized access

- GPS modules for location tracking and cold chain asset tracking

Connectivity Protocols:

- Cellular (4G/5G): High bandwidth for frequent transmission and remote locations

- WiFi: Cost-effective for warehouse and facility monitoring

- LoRaWAN: Low-power, long-range connectivity for rural transport routes

- Satellite: Coverage in areas without terrestrial networks

Choosing between these connectivity options is a survival strategy. Routes with poor coverage require fallback mechanisms or local buffering to avoid data loss during transport. Without this, you may only discover critical temperature breaches hours after they’ve occurred.

Cold Chain IoT Architecture Overview

Edge Layer: Battery-powered sensors collect environmental data at 1-15 minute intervals. Advanced sensors incorporate edge computing to process data locally, reducing bandwidth consumption and enabling immediate threshold alerts for real-time cold chain monitoring.

These edge capabilities become essential in remote areas where connectivity drops, allowing the system to detect anomalies and trigger alarms locally, even without cloud access.

Network Layer: Multi-protocol strategies automatically switch between cellular, WiFi, and LoRaWAN based on availability and cost. When refrigerated trucks hit cellular dead zones, systems store data locally and upload it when connectivity returns, ensuring zero data loss.

But coverage isn’t guaranteed. Unmonitored segments — border crossings, rural highways, isolated ports — remain significant risks. The solution isn’t just technical; it’s architectural. Build in failure. Assume downtime — design systems to queue and replay data reliably when links reappear.

Cloud Processing Layer: Centralized platforms aggregate sensor data and generate actionable insights through real-time dashboard visualization, automated alert escalation, predictive analytics for equipment maintenance, and integration APIs for existing systems.

|

Architecture Component |

Technology Options |

Key Considerations |

|

Sensors |

Bluetooth, LoRaWAN, Cellular |

Battery life, accuracy, cost per unit |

|

Connectivity |

WiFi, 4G/5G, Satellite, LoRaWAN |

Coverage area, data costs, latency |

|

Software |

Cloud-native, Hybrid, On-premise |

Security, scalability, integration needs |

One of the most overlooked parts of the architecture is resilience. Cold chain systems must be designed to handle ideal conditions and the moments when trucks cross remote areas with no signal, devices fail mid-route, or APIs experience latency. Fault tolerance must be baked into every layer.

Data Integrity and Compliance Framework

Regulatory compliance forms the backbone of pharmaceutical cold chain management. FDA 21 CFR Part 11 regulations require electronic records to be as reliable as paper records, demanding comprehensive validation, audit trails, and electronic signature capabilities. EU GDP guidelines mandate continuous temperature monitoring with documented investigation procedures for every deviation.

Every regulatory body wants traceability, but each defines it differently. That’s where most systems break down. Automating audit trails isn’t hard. Proving to a foreign regulator that your system aligns with their language is.

Validation Requirements:

- Sensor calibration certificates traceable to NIST standards

- Software validation documentation (IQ/OQ/PQ protocols)

- Change control procedures for system modifications

- User access controls with unique identification

Audit Trail Specifications:

- Immutable timestamp records for all sensor readings

- Complete user activity logs

- Data export in FDA-acceptable formats

- Backup and disaster recovery procedures

Global supply chains face compliance complexity. The same monitoring platform must often satisfy multiple overlapping regulations across different countries. Failure to adapt to local documentation formats or inspection protocols can invalidate an entire batch of goods, even if the technology functions perfectly.

Implementation Challenges in Cold Chain IoT Solutions

Choosing the right connectivity model — cellular, Wi-Fi, LoRaWAN, or even satellite — isn’t just about data transmission. It directly affects battery life, coverage, costs, and system resiliency. Every decision has trade-offs, and most implementation failures stem from not considering those trade-offs in real-world conditions.

Power Management: Medical sensors require careful balance between connectivity options and battery life. Different communication protocols offer varying power consumption profiles: LoRaWAN enables 10-year battery life through ultra-low power transmission and optimized measurement cycles, while cellular connectivity provides real-time alerts but significantly reduces operational lifespan. WiFi and Bluetooth offer middle-ground solutions for different deployment scenarios. Strategic power management becomes critical for remote temperature monitoring in cold chain applications, where connectivity choice directly impacts maintenance requirements and operational costs.

Connectivity Gaps: Rural routes and international shipping create communication dead zones that can leave perishables unmonitored. Hybrid approaches using cellular backup for LoRaWAN sensors ensure data continuity during coverage interruptions through store-and-forward capabilities.

Data Security: Cold storage monitoring system deployments require robust security frameworks that protect sensitive supply chain data. Essential measures include end-to-end encryption (AES-256), certificate-based device authentication, regular security patches, and network segmentation for sensor traffic.

Global Scalability: Multi-national deployments face regulatory variations, carrier compatibility issues, and time zone complexities. Successful IoT for perishable goods tracking implementations require standardized hardware platforms with region-specific connectivity modules and localized compliance reporting capabilities.

Projects usually fail at these challenges, not because of flawed technology but because real-world complexity was underestimated. Planning for bad signals, battery drops, customs bottlenecks, and documentation mismatches isn’t optional — it’s where successful architecture begins.

Key Protection Mechanisms

Continuous Vigilance: Unlike periodic manual checks, IoT sensors provide 24/7 monitoring. They detect temperature excursions within minutes rather than hours or days, preventing spoilage before it occurs.

Immediate Response: Real-time alerts enable instant corrective action. When sensors detect temperature drift, effective systems automatically contact drivers, identify service locations, and update delivery schedules, transforming monitoring from reactive alerts into predictive business intelligence.

Documentation Shield: Automated compliance reporting creates an unbreakable audit trail that protects against regulatory penalties and proves due diligence in case of disputes or investigations.

Predictive Protection: Advanced analytics identify patterns that predict equipment failures before they compromise cargo, enabling proactive maintenance that prevents losses.

The key difference between successful and failed deployments is integrating business processes from day one. Effective cold chain IoT solutions protect perishables by enabling immediate intervention when conditions threaten product integrity.

What Are the Must-Have Features of Cold Chain IoT Monitoring Systems?

Selecting the right cold chain monitoring technology determines whether your investment protects product integrity or becomes expensive shelfware gathering dust. The difference between success and failure lies in understanding three critical system layers: hardware precision that survives logistics hell, connectivity architecture that adapts to global operations, and compliance frameworks that satisfy the most demanding regulatory oversight.

Essential Hardware Components

Hardware components form the foundation of reliable monitoring systems that enable organizations to achieve a 40-60% reduction in product losses:

Cold chain temperature monitoring devices with pharmaceutical-grade precision: Temperature accuracy requirements vary by application, with pharmaceuticals demanding ±0.1°C precision while food products typically require ±0.5°C accuracy.

High-precision environmental sensors: Response times under 30 seconds enable rapid detection of temperature changes, while operating ranges from -80°C to +70°C cover ultra-cold storage requirements with IP67/IP68 environmental ratings.

Advanced power management systems: Primary lithium batteries provide a 5-10 year operational life and low-power sleep modes that reduce consumption below 10μA, supporting extended deployments.

Rugged construction specifications: Shock resistance up to 1500G handles transport abuse, while operating humidity ranges of 0-95% non-condensing accommodate diverse climate conditions.

Food-safe and compliant materials: FDA-approved plastics meet regulatory requirements with EMC compliance, ensuring interference-free operation near refrigeration equipment.

Critical hardware features include GPS modules for location tracking, door/light sensors indicating unauthorized access, and vibration detectors for handling quality assessment.

IoT Architecture for Perishable Goods Tracking

Modern connectivity infrastructure must adapt to diverse operational environments where pharmaceutical shipments traverse urban cellular coverage, rural highways, and international borders:

Multi-protocol connectivity solutions: LoRaWAN provides 15km range in open areas and 2-5km coverage in urban environments, while NB-IoT and Cat-M1 cellular protocols offer global carrier support with deep building penetration.

Edge computing capabilities: Local data processing reduces bandwidth requirements by 80-90% while enabling immediate threshold alerts without cloud dependency, transforming sensor networks into intelligent monitoring systems.

Comprehensive API integration frameworks: RESTful APIs supporting real-time queries connect sensor data to business systems, webhook notifications deliver immediate alerts, and the MQTT protocol supports integration with industrial IoT platforms.

Global scalability architecture: Standardized hardware platforms with region-specific connectivity modules balance operational consistency with local requirements while minimizing training complexity.

Enhanced Security and Compliance Features

Pharmaceutical cold chain management operates under strict regulatory oversight, where documentation gaps trigger costly product recalls, with regulatory violations averaging $2.5 million in the pharmaceutical industry:

Automated regulatory compliance systems: Building on the previously established FDA 21 CFR Part 11 and EU GDP framework, computerized systems reduce audit preparation time by 75% through continuous documentation and reporting.

Advanced security frameworks: End-to-end AES-256 encryption secures all data pathways with certificate-based device authentication, preventing unauthorized access, while role-based access controls limit system access based on job functions.

Comprehensive data management: Immutable audit trails with blockchain verification options provide tamper-proof documentation, while 21+ year data retention with automated archival policies meet pharmaceutical industry requirements.

Cloud-agnostic deployment options: Support for AWS, Azure, and Google Cloud platforms with real-time data replication and disaster recovery capabilities protects against system failures.

GDPR compliance features: Data residency and privacy controls protect personal data in EU operations, while regular security audits with penetration testing maintain protection against evolving threats.

What Key Decisions Impact Cold Chain Monitoring?

Beyond technical specifications and compliance requirements, successful cold chain IoT deployments hinge on four critical implementation decisions that determine whether projects deliver promised ROI or become expensive failures.

Integration Complexity and Enterprise System Connectivity

Modern IoT platforms provide pre-built connectors for major enterprise systems, including SAP, Oracle WMS, Manhattan Associates, and JDA. Standard implementations using RESTful APIs and webhook notifications typically require 2-4 weeks for deployment. The platform can push temperature excursion alerts directly into existing incident management workflows, automatically update inventory status based on environmental conditions, and generate compliance reports within current document management systems.

Custom integrations for proprietary systems may require additional development time, but leading platforms offer flexible API frameworks supporting real-time data exchange, batch processing, and historical data synchronization. Evaluate platforms providing sandbox environments and detailed API documentation to reduce integration complexity and testing time.

Pharmaceutical Validation and Regulatory Compliance

Pharmaceutical applications demand comprehensive validation following ICH Q7 guidelines and FDA Process Validation Guidance. The validation process encompasses Installation Qualification (IQ), verifying proper installation, Operational Qualification (OQ), confirming system functions meet specifications, and Performance Qualification (PQ), demonstrating consistent performance under actual operating conditions.

Sensor calibration must maintain traceability to NIST standards, with certificates provided for each device. Software validation requires documented evidence of system functionality, including user acceptance testing, security verification, and change control procedures. Pharmaceutical-grade platforms typically provide validation support packages including pre-qualified hardware, validation protocols, and regulatory documentation to streamline qualification processes and reduce internal resource requirements.

Global Scalability and Multi-Regional Deployment

Global deployments encounter varying connectivity standards, regulatory frameworks, and data sovereignty requirements. Leading platforms provide region-specific hardware configurations supporting local cellular carriers and communication protocols. European deployments might emphasize LoRaWAN connectivity while North American installations favor cellular networks.

Data residency requirements demand distributed cloud architectures that store EU data within European Union boundaries while maintaining global visibility for multinational operations. Effective platforms support multiple regulatory reporting formats simultaneously, enabling the same sensor data to generate FDA-compliant reports for US operations and EU GDP documentation for European distribution. Prioritize solutions offering local support teams and regulatory expertise in each operating region.

Cybersecurity and Data Protection Framework

Cold chain data represents valuable intellectual property about supply chain operations, product movements, and business relationships requiring enterprise-grade security. Essential protection measures include device-level encryption, preventing data interception, network segmentation isolating sensor traffic from corporate networks, and regular security auditing by third-party firms.

Certificate-based device authentication ensures only authorized sensors connect to networks, while role-based access controls limit user permissions based on job functions. Evaluate platforms maintaining ISO 27001 certification, SOC 2 Type II compliance, and regular penetration testing. Multi-factor authentication, automated security patch management, and incident response procedures provide additional protection against evolving cybersecurity threats.

Still comparing options?

Let Perplexity break down the pros and cons for your project or contact our experts.

Why Choose Yalantis as Your IoT Development Partner?

Cold chain monitoring solutions are not off-the-shelf plug-and-play systems. They require deep industry expertise, regulatory knowledge, scalable architecture design, and seamless integration with enterprise ecosystems. Yalantis brings years of experience delivering end-to-end IoT platforms — from sensor selection and hardware integration to cloud infrastructure, predictive analytics, and compliance automation.

Here’s why leading healthcare firms partner with Yalantis:

- Proven expertise in IoT, logistics, and healthcare domains

- End-to-end service delivery: hardware, firmware, cloud, mobile apps

- Dedicated compliance consultants for FDA, EU GDP, HIPAA, and more

- Rapid prototyping and iterative development using agile methodologies

- Onshore and offshore delivery centers with 24/7 support

With Yalantis, clients gain a long-term technology partner who builds robust systems and helps you operationalize them through training, change management, and continuous innovation.

Conclusion

Cold chain IoT solutions transform supply chain operations from reactive crisis management into predictive protection systems. The combination of pharmaceutical-grade hardware, multi-protocol connectivity, and regulatory compliance frameworks creates a comprehensive defense against temperature-controlled logistics failures that cost the industry billions annually.

Modern cold chain monitoring systems deliver measurable protection through continuous environmental surveillance, immediate alert systems, and comprehensive documentation trails. Companies handling temperature-sensitive products worth millions can no longer afford monitoring gaps that leave shipments vulnerable during critical transport moments.

Ready to protect your temperature-sensitive products with precision monitoring?

Contact our cold chain IoT specialists to discuss your monitoring requirements and compliance needs.

FAQ

How can IoT-based cold chain monitoring reduce spoilage risks compared to traditional methods?

IoT cold chain monitoring provides continuous real-time surveillance versus periodic manual checks that miss critical temperature excursions. Organizations implementing IoT temperature monitoring systems see a 40-60% reduction in product losses through immediate alerts, predictive analytics for equipment failure, and automated corrective actions. Traditional data loggers only reveal problems after damage occurs, while IoT systems prevent spoilage through instant intervention capabilities.

What specific technologies enable real-time temperature tracking across global logistics networks?

Real-time cold chain monitoring combines multiple connectivity protocols: LoRaWAN for 15km range coverage, cellular 4G/5G for remote locations, WiFi for warehouse environments, and satellite backup for international routes. Edge computing processes data locally, reducing bandwidth by 80-90% while enabling immediate threshold alerts. GPS integration tracks location while pharmaceutical-grade sensors maintain ±0.1°C accuracy throughout transport.

Does Yalantis provide complete development services for pharmaceutical cold chain management systems?

Yes, Yalantis delivers end-to-end cold chain IoT solutions, including hardware integration, connectivity architecture, compliance frameworks, and business system integration. Our development covers FDA 21 CFR Part 11 compliance, EU GDP requirements, real-time monitoring dashboards, and API integration with existing ERP and WMS platforms. We handle everything from sensor deployment to regulatory documentation.

How do you ensure cold chain monitoring systems meet FDA and international compliance standards?

Cold chain compliance requires automated documentation systems with immutable audit trails, NIST-traceable sensor calibration, and electronic signature capabilities. Our systems simultaneously support FDA 21 CFR Part 11, EU GDP, HACCP, and USP protocols. Automated compliance reporting reduces audit preparation time by 75% while maintaining 21+ year data retention with blockchain verification options for tamper-proof documentation.

Which industries see the highest ROI from cold chain asset tracking implementations?

Pharmaceutical companies handling temperature-sensitive biologics, vaccines, and oncology treatments see immediate ROI due to high product values and strict regulatory requirements. Food and beverage companies monitoring perishable goods across long distribution networks also benefit significantly. Any organization where temperature deviation equals total product loss rather than quality degradation justifies an IoT cold chain management investment.

Can IoT monitoring integrate with our existing warehouse management and fleet tracking software?

Modern cold storage monitoring systems provide comprehensive API integration through RESTful endpoints, webhook notifications, and MQTT protocols. We connect sensor data to existing ERP, WMS, and fleet management platforms while maintaining data sovereignty requirements. Integration includes real-time alerts, historical reporting, and automated workflow triggers that enhance existing business processes without system replacement.