Designing sensors for medical devices is a multi-step process that begins with selecting the right sensor type and quickly expands into more complex stages, including security, latency, compliance, communication, firmware, and hardware.

If that already sounds like a lot, it’s because it is. Building IoT healthcare sensors requires a high level of precision and cross-disciplinary expertise. Don’t worry, though. This post has got you covered with best practices. Read it if you’re a:

- CTO or tech lead at a medical device company

- product owner or developer of healthcare IoT

- IoT consultant or system architect of medical sensors

- R&D team working on wearable biosensors

With IoT solutions for healthcare developed over more than 15 years, we’ve supported everything from IoT-enhanced telehealth platform rollouts to consumer-focused fitness trackers for startups like Healthfully. Drawing on this experience, we’ll explain what it takes to design high-performing, regulatory-ready sensors for medical devices.

Highlights:

- start with purpose-built sensor types — from blood pressure to body temperature sensors, each has unique data, power source, and integration needs

- mind that sensor data collected means nothing without the “big 3”: secure connectivity, low-latency processing, and compliance with medical device regulations, such as FDA, CE, ISO 13485, or ISO 14971

- optimize firmware for fast processing, make hardware energy-efficient, miniature, and wearable

- remember that balancing size, comfort, and accuracy is an art, especially in wearable sensing technologies

How to Actually Design Sensors for Medical Devices?

Designing medical sensors for IoT integration means determining what the sensor needs to measure, how it captures and transmits that data, what actions it should trigger, how it communicates with other systems, and whether it meets the required performance, safety, and regulatory standards.

Let’s now go through these considerations.

Choose the Right Type of Sensor

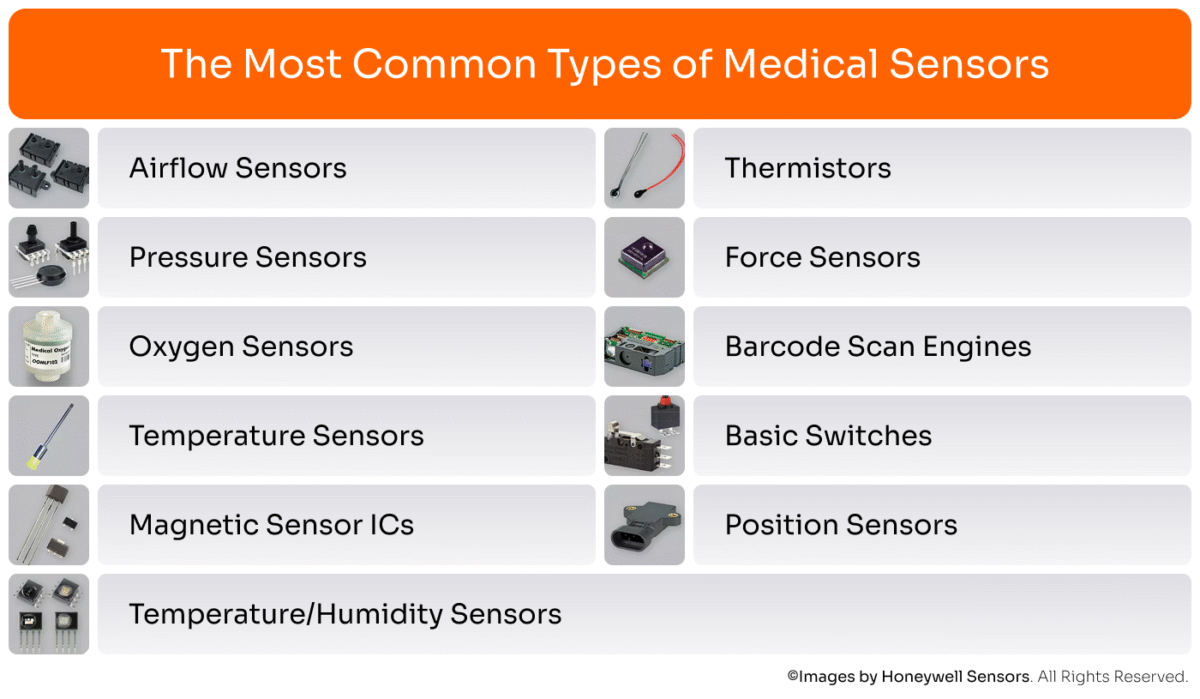

The choice of medical device sensors depends entirely on the physiological parameters you need to capture and the medical applications — in other words, use cases. Here are the most common types of medical sensors:

- Pressure sensors. Measure changes in pressure from air, gas, or fluids. You’ll find them in infusion pumps, blood pressure monitors, and respiratory medical devices.

- Temperature sensors. Measure human body or ambient temperature variations. They are used in everything from basic thermometers to cold-chain monitoring for vaccines.

- Force sensors. Measure applied pressure or force — used in prosthetics, infusion pumps, or surgical tools to ensure controlled application of force.

- Biopotential sensors. Detect electrical activity in the body and are common in ECG, EEG, and EMG.

- Motion sensors. Detect movement and orientation. Think of accelerometers and gyroscopes used in fall detection systems or rehabilitation medical devices.

- Optical sensors. Use light for non-invasive measurements. Pulse oximeters, which monitor light absorption to measure blood oxygen levels, are a prime example.

- Biochemical sensors. Detect and measure chemical substances in biological samples. Examples include glucose and pH sensors.

- Airflow sensors. Monitor breathing or ventilator performance. They detect the air movement rate and volume, crucial in respiratory therapy and sleep apnea medical devices.

All the above can also be divided into invasive, non-contact, and wearable sensors. Here’s an example of a non-contact one:

Design for Medical Sensor Requirements

Beyond collecting data, medical sensors and wearable technology must integrate into the wider healthcare ecosystem. Here, a few non-negotiables appear:

- end-to-end encryption (TLS/AES), anonymization, and pseudonymization for data security and privacy

- HIPAA or GDPR compliance for health data protection

- FDA, CE, ISO 13485, and ISO 14971 compliance for medical device safety

- low-latency communication for continuous, real-time monitoring and time-sensitive alerts

Develop Embedded Software and Firmware Carefully

Embedded software and firmware enable your sensor to perform its intended functions. They handle everything from data acquisition to wireless communication and power management. Here’s what to account for during custom firmware development:

- efficient coding to avoid overloading memory or power

- edge processing for filtering or compressing signals before they’re sent

- secure boot and OTA update mechanisms

- error handling, recovery mechanisms, and fail-safes for mission-critical use

Select the Right Communication Protocol

For health sensors to communicate smoothly, choose the protocol based on your power needs, range, and data volume. Here’s a comparison of the most popular solutions:

|

Protocol |

Power Efficiency |

Range |

Data Rate |

Best For |

|

Bluetooth Low Energy |

Very High |

10–100 meters |

Low–Medium |

Wearables, mobile health medical devices |

|

Wi-Fi |

Low |

~50 meters |

High |

In-hospital, continuous monitoring, large data sets |

|

NB-IoT/LTE-M |

High |

Wide area |

Low–Medium |

Remote patient monitoring in rural areas |

|

Zigbee |

High |

10–100 meters |

Low–Medium |

Sensor networks in clinical facilities |

Address Hardware Constraints Early

Many developers underestimate the trade-offs required to make a sensor wearable, durable, and energy-efficient. Hardware design should focus on:

- low power consumption using sleep modes, efficient MCUs, and energy-aware firmware

- miniaturization, especially for earables, patches, or implantables

- wearability and comfort, including skin-safe adhesives, waterproof enclosures, and flexible PCBs

- battery longevity — supporting days or weeks of work without charging

Designed your sensors?

Now you need software to make them work. We guide the entire process from concept to deployment.

What Makes a Medical Sensor Effective in the Real World?

Wearable medical sensors must be secure and contain certain features (say, reliability, low power consumption, and OTA updates) to be truly effective in real-world settings. Let’s explore these and other essentials:

Must-Have Features of Wearable Sensors

The integral features of healthcare sensors include the following:

- High data accuracy and reliability. In clinical use, a wrong data point can lead to irreversible consequences. That’s why sensors should maintain a low error margin (typically less than 5%) even under movement, sweat, or long wear.

- Power efficiency. As we mentioned earlier, wearable health sensors must operate for extended periods without requiring constant recharging. This may require using low-power communication protocols and optimized firmware.

- Compact, ergonomic form factor. Another must-have feature is the sensor size. When made smaller and lighter — that is, more comfortable — it’s more likely to be used consistently.

- Interoperability. Medical wearable sensors should connect to other systems, including EHRs, telehealth platforms, remote patient monitoring systems, or mobile apps. Why? This helps avoid data silos.

- OTA update capability. Allows medical devices in the field to receive firmware or algorithm updates securely — without pulling them from service.

IoT Communication and Security for Medical Devices

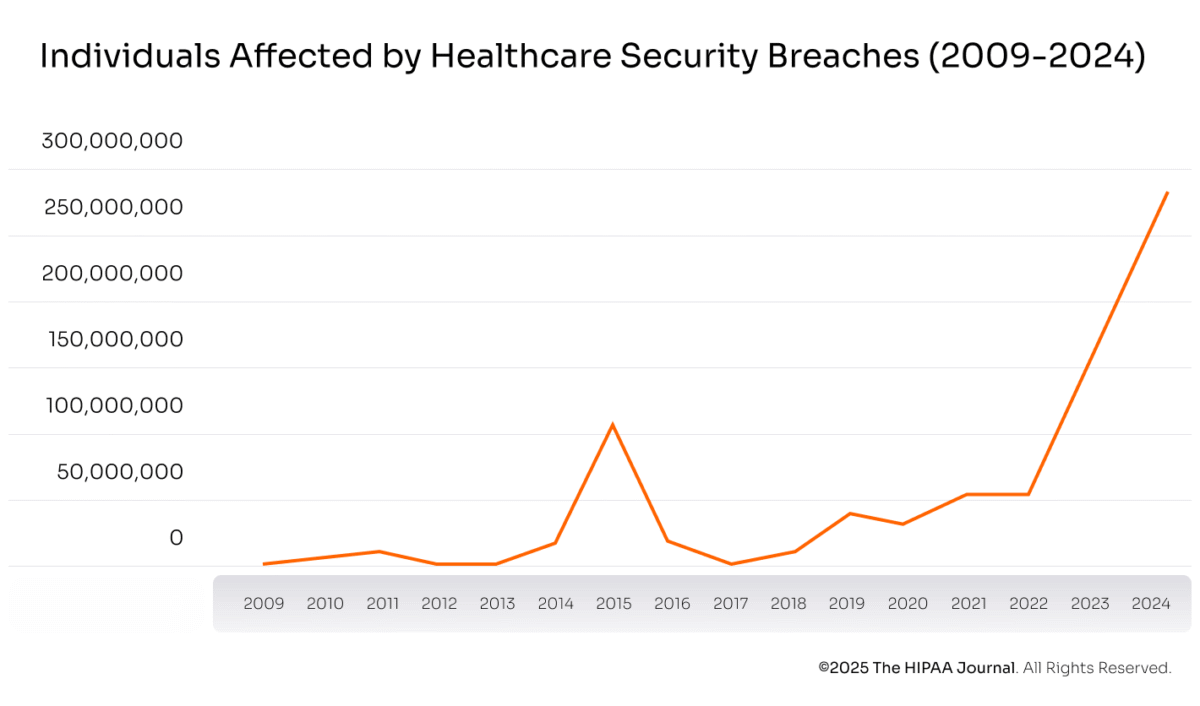

In 2023, nearly two healthcare data breaches of over 500 records were reported every single day. That translated to over 364,000 compromised records daily, and the trend only worsened in 2024. Last year alone, attackers gained access to the protected health information of more than 276 million individuals, or over 750,000 records per day.

For medical devices, these numbers are beyond alarming. Here’s why.

Each medical sensor is a potential entry point for a hack. A misconfigured Bluetooth module or unsecured data transfer process can expose highly sensitive health information, from vital signs to diagnoses, to malicious actors. That’s why secure communication protocols, encrypted data transmission, and rigorous access controls aren’t optional features. They’re part of the device’s core functionality.

Challenges in Medical Sensor Design

Creating sensors for wearable healthcare apps is a constant balancing act between performance and energy efficiency, comfort and aesthetics, data accuracy and minimal intrusiveness. Let’s take a closer look at these hurdles:

- Motion artifacts and signal noise. Wearable body sensors work under real-world conditions — walking, sweating, sleeping. Filtering and signal conditioning are needed to avoid false alarms.

- Power and performance trade-offs. Processing real-time data locally saves battery but risks overloading low-power MCUs. Offloading to a gateway can help, but not in low-connectivity environments.

- Regulatory delays. Even if the medical sensor is ready, certification can take anywhere from 6 to 12 months. It’s especially true when launching in multiple countries.

- User acceptance. No matter how performant the sensor is, if the device is uncomfortable, patients won’t wear it.

How Yalantis Helps Develop IoT-Connected Medical Sensors

Success in medical IoT product design largely depends on the right sensors, but also smart data handling, tight security, and seamless user experiences. Here are two examples of projects Yalantis delivered:

Telehealth Insights with Medical Devices

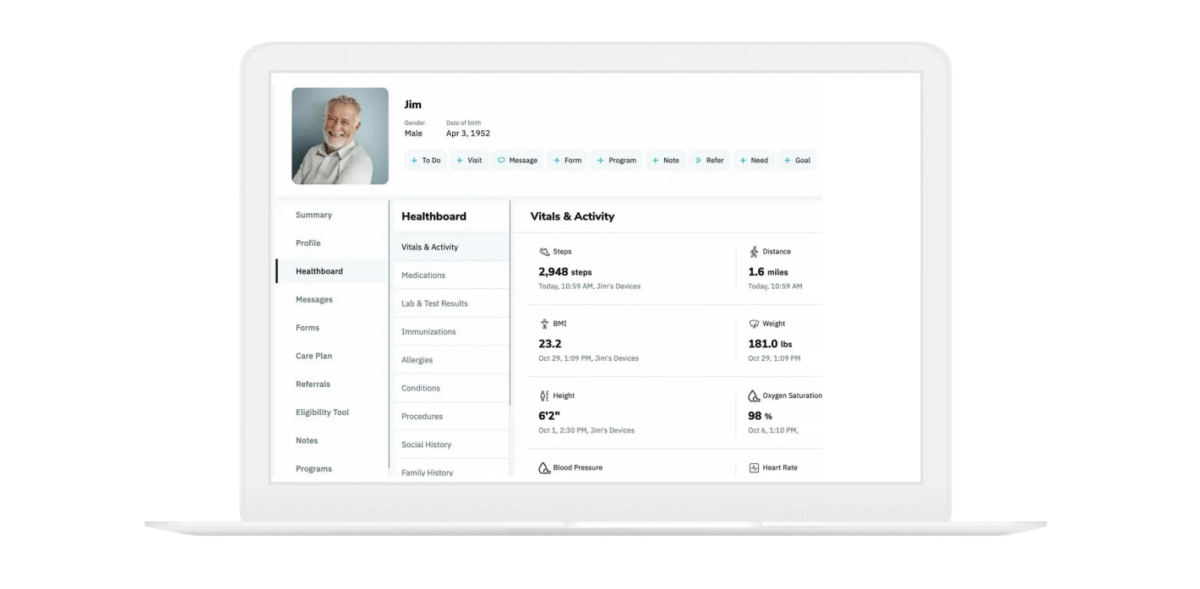

This case study shows how optimizing IoT data collection and flow improved clinical decision-making for a telehealth platform serving patients from rural areas.

In particular, our client needed a way to transform fragmented sensor data (including heart rate, blood pressure, oxygen saturation, daily activity, and more) into a cohesive, clinician-friendly format. Here’s what we implemented:

- Integration with medical devices. We connected the platform to Bluetooth-enabled EKG monitors, BP cuffs, and oximeters using vendor SDKs.

- Support for commercial fitness wearables. To capture daily trends and enable remote monitoring, we integrated with popular consumer wearable devices, such as Fitbits and Apple Watches.

- Data flow optimization. To avoid overwhelming medical professionals with unfiltered data, we built a schedule-based control system that processes incoming sensor data, summarizes it, and surfaces only medically relevant, reliable measurements.

- Cost-effective storage. We developed a data compression and archiving flow to reduce cloud costs.

- Privacy-first design. Our solution uses secure device pairing codes and HL7-compliant encryption to route sensitive data from medical devices to EHRs safely.

Seamless Fitness Device Integration for a Scalable Patient App

This case study highlights how standardizing data flows and security protocols enabled a Healthfully patient-facing app to integrate with over five third-party fitness tracker ecosystems.

The Healthfully team needed to connect multiple platforms — Apple Watch, Fitbit, Withings, Google Fit, and iHealth — within a single app. But hardware peculiarities, sync frequency, and medical technology regulatory gaps made it complex.

Here’s how we solved it:

- Custom data access layers per device. We used separate, native APIs to integrate each of the wearable devices.

- Unified data pipeline. We created a system that consolidates and merges data from multiple sources, even when formats or timestamps vary.

- Security-first architecture. Each piece of data is encrypted, securely stored in the cloud, and fully compliant with HIPAA and other medical sensors requirements.

- User-driven privacy controls. Patients manage who can access health conditions data from their fitness devices.

Conclusion

To create wearable sensors for health monitoring that would perfectly fit into medical devices, you need to balance lots of things. Functionality and power efficiency, patient comfort and data quality, strict regulatory demands and seamless integrations — all these require careful attention.

Let’s recap what matters most:

- picking the right type of sensor technology from the very beginning

- focusing on security, privacy, low latency, and compliance

- developing efficient, reliable, low-power-use firmware

- keeping hardware limitations and peculiarities in mind

- ensuring smooth communication and integration with other systems

And finally, collaborating with skilled experts. This matters because designing wearable bio sensors demands experience across software, hardware, and healthcare workflows — something a partner can offer.

Need help designing medical sensors?

FAQ

How much does it cost to develop IoT-connected biometric sensors?

The cost of creating wearable sensors for remote health monitoring largely depends on your specific requirements and the overall project complexity. A basic MVP typically ranges from $50,000 to $200,000. Want a more precise estimate? Just share your specs and we’ll help scope it.

Can Yalantis assist with medical device firmware development?

That’s for sure. Yalantis experts have over 15 years of experience in IoT, with firmware development included. We handle bootloaders, OS integration, medical device drivers, and secure app logic — all for low-power, reliable sensors in healthcare.

Do you provide end-to-end IoT solutions for the healthcare industry?

We do. Our team covers every stage of IoT, from building medical software and firmware to delivering medical devices. Besides that, we support prototyping, connectivity, data handling, and compliance.

How long does it take to develop a wearable healthcare sensor?

Years, actually. Or no less than a year if you’re building wearable sensors for human health monitoring from scratch. The process is quite lengthy because it requires thorough research and prototyping, wearable design, extensive documentation, numerous clinical trials and medical procedures, testing, and, finally, delegating production to a sensor manufacturer.

Can you help with HIPAA/GDPR compliance for health monitoring devices?

Absolutely. Yalantis designs body sensors with security and privacy in mind. We use data encryption procedures as well as ensure compliance with HIPAA, GDPR, and plenty of other medical sensors requirements.