Long gone are the days when cars were mechanical machines. Modern vehicles, especially EVs, ADAS, and software-defined vehicles, are complicated electronic ecosystems.

From safety-critical control units to infotainment systems and real-time battery monitoring, virtually every system depends on strong, precisely engineered PCB design for automotive electronics.

In this article, you’ll learn:

- Why smart PCB design is crucial to vehicle reliability in 2025

- How to select the right type of automotive PCB from the start

- What trends are shaping the future of PCB development

- How design impacts assembly, compliance, and cost

- How Yalantis solves integration challenges through end-to-end services

Whether you’re leading R&D, procurement, or system engineering, this material will help you avoid pitfalls and gain a strategic edge through smarter automotive circuit board design.

Why PCB Design is Critical to Vehicle Reliability

As functionality grows, so does the risk. A decent part of field failures in automotive electronics can be traced back to PCB-level issues such as thermal stress, EMI, or design flaws. In an industry where recalls can cost millions, and where safety and compliance are non-negotiable, poor PCB design is not an option.

With the advancement and complication of vehicle electronics, the role of printed circuit boards in vehicles has shifted from supportive to a must-have feature for a vehicle’s lifecycle. Inferior PCB design increases the risk of performance problems, safety failures, and expensive recalls. Here are some arguments on the importance of proper PCB design for automotive electronics for vehicle reliability:

Thermal Management and Power Integrity

Automotive PCBs are required to efficiently manage heat generated by high-power components, which is especially crucial for EVs with inverters, BMS units, and onboard chargers running hot. The absence of thoughtful thermal pathways leads to heat buildup, which can degrade components and lead to various instabilities.

Real-world risk: Poor thermal management can cause sudden voltage drops or component failure in battery management systems, risking EV shutdown or fire hazards.

Slot Constraints in EV and Embedded Systems

The majority of today’s electronic vehicles require compact and lightweight designs. PCBs must be densely packed without sacrificing performance and striving to keep the optimal manufacturability. High-density interconnect (HDI) and rigid-flex designs are now the benchmark, making automotive circuit board design a decent compromise between form and function.

Real-world risk: Poor layout in confined areas can cause trace overlap, shorts, or cooling issues, leading to erratic behavior in control modules or infotainment blackouts.

EMI/EMC Compliance for ADAS and Infotainment

Modern vehicles are packed with sensors, cameras, and wireless modules. Electromagnetic interference (EMI) and lack of electromagnetic compatibility (EMC) shielding can disrupt advanced driver-assistance systems (ADAS) or infotainment.

Real-world risk: Failing to meet EMI/EMC thresholds can result in sensor blindness or communication errors, putting up the risk for safety issues and regulatory approval.

Resilience in Harsh Operating Environments

Automotive PCBs encounter constant vibration, temperature shifts, and exposure to moisture and contaminants. Without vital material choices and mechanical reinforcement, these environmental factors can degrade vehicle PCBS over time.

Real-world risk: A poorly reinforced PCB in a powertrain control unit can suffer cracked solder joints or delamination, leading to loss of engine or braking control under stress.

Meeting Compliance Standards (ISO 26262, IPC)

Designing printed circuit boards in vehicle electronics isn’t just about functionality, but a huge part of it is about certifiability. Automotive systems tied to safety (e.g., braking, steering, battery management) must follow standards like ISO 26262 for functional safety and IPC standards like IPC-6012DA for board quality.

Real-world risk: Non-compliant PCB design for vehicle control systems can block vehicle certification, delay launches, and damage supplier reputations, especially in tightly regulated markets like the EU or US.

Need expert assistance in PCB-related challenges?

Explore our servicesChoosing the Right PCB Type

Obviously, not all printed circuit boards in vehicles are created equal. Selecting the wrong type of PCB early in development can lead to integration issues, overheating, signal loss, or worse, costly design rework late in the cycle. In the context of PCB design for automotive electronics, the type of board chosen must align with the performance, space, and durability requirements of the specific system.

|

PCB Type |

Description |

Typical Automotive Use |

|

Single-layer |

Basic board with one layer of conductive material. |

Lighting systems, basic sensors, simple control circuits |

|

Double-layer |

Conductive layers on both sides for moderate complexity. |

Dashboard controls, HVAC systems, indicator clusters |

|

Multilayer |

Multiple signal layers for dense, high-speed designs. |

ADAS modules, infotainment, power converters in EVs |

|

Rigid-Flex / Flex |

Combines flexibility and rigidity for 3D mounting and space-constrained areas. |

Steering columns, airbags, BMS units, foldable displays |

Each type plays a specific role in deciding on how to optimize vehicle electronics with PCBs. Here’s a breakdown of the importance of matching the right type to the function.

Single-Layer PCBs: dedicated simplicity

For non-critical, low-power applications, single-layer automotive PCBS offer cost-effective reliability. These are ideal where complexity is minimal, but durability still matters.

Why it matters: Overengineering simple systems with complex PCBs adds unnecessary cost and weight.

Double-Layer PCBs: industry standard in most modules

Used widely in designing automotive PCB systems where moderate complexity and size balance are needed, such as driver dashboards or seat control units.

Why it matters: Choosing a double-layer PCB when one isn’t enough but a multilayer would be overkill keeps manufacturing efficient and scalable.

Multilayer PCBs: the brain inside smart vehicles

Complex vehicle PCBS for infotainment, ADAS, and electric drivetrain systems rely on multilayer boards. These support high-speed signals, dense layouts, and EMI shielding essential to PCB design for vehicle control systems.

Why it matters: Poorly designed multilayer PCBs can lead to signal integrity issues or overheating in critical subsystems.

Rigid-Flex and Flex PCBs: made for movement and tight spaces

These PCBs are crucial in areas exposed to constant motion or confined installation. Designing printed circuit boards for vehicles with flex elements allows integration into steering wheels, airbags, and folding or wearable modules.

Why it matters: Inadequate flex design can cause cracks or fatigue, leading to mechanical or electrical failure in motion-critical zones.

Emerging Automotive PCB Trends for 2025

As vehicles get more intelligent, electrified, and software-defined, the role and importance of PCB design in automotive systems increase. Becoming a strategic part of vehicle’s safety, performance, and industry progress, automotive PCBs are no longer passive components. Here’s our vision of automotive PCB trends in 2025:

What are the main areas PCBs are used in today?

Today’s vehicles may contain hundreds of electronic control units (ECUs), each powered by custom printed circuit boards in vehicle electronics. Here are the most critical applications of vehicle PCBs:

- Battery Management Systems (BMS): monitor cell health, temperature, and charging to ensure electric cars’ safety and longevity.

- Powertrain Controllers (Especially in EVs): handle inverter operations, torque control, and motor synchronization in electric drivetrains.

- Advanced Driver-Assistance Systems (ADAS): support cameras, radar, and processing units helping with lane assist, braking, and avoiding collisions.

- Infotainment Systems: power media centers, connectivity modules, and display touchscreens.

- Instrument Clusters and Dashboards: drive digital gauges, HUDs, and critical driving feedback.

- Lighting (Interior/Exterior): control adaptive headlights, LED animations, and ambient interior lighting.

- Climate Control Systems: ensure precision control of heating, ventilation, and air conditioning subsystems.

- Electronic Control Units (ECUs): the digital backbone of automotive subsystems, which is everything from braking to steering.

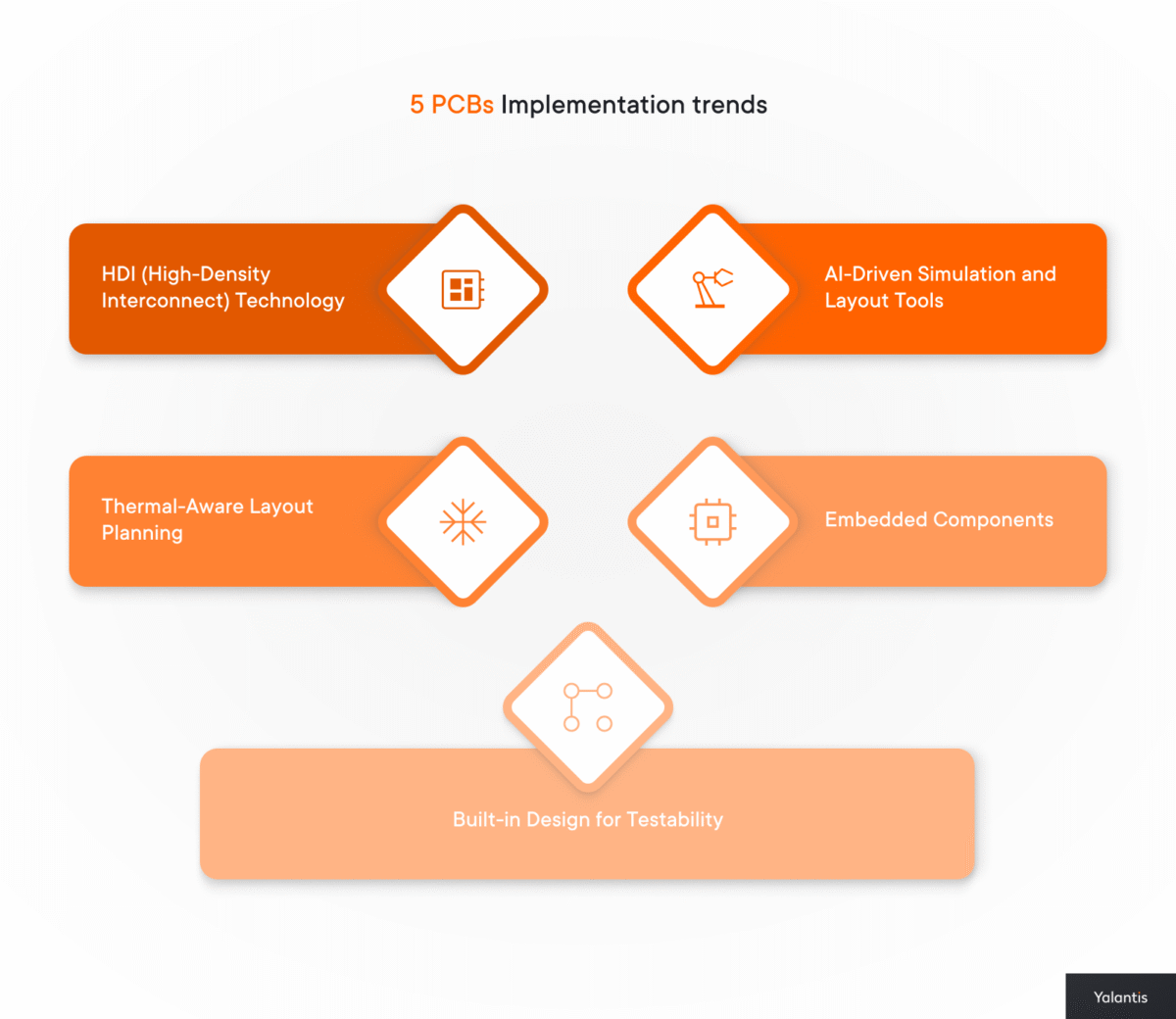

Top 5 PCBs Implementation trends Yalantis recommends following

HDI (High-Density Interconnect) Technology

Qualifies for more complex, multilayer designs in smaller footprints, which is great for space-constrained systems like ADAS and wearable in-car tech.

Why it matters: HDI enables vehicle PCB optimization without a little to no performance compromise or signal quality loss.

AI-Driven Simulation and Layout Tools

Suggests optimal trace routing, minimizes EMI, and reduces design iterations via machine learning.

Why it matters: AI shortens time-to-market while boosting reliability in PCB design for automotive electronics.

Thermal-Aware Layout Planning

Automatically recognizes and mitigates heat-intensive zones during the design phase, preventing downstream reliability subjects.

Why it matters: Crucial for EVs and infotainment systems where thermal failure can mean complete system shutdown.

Embedded Components

Integrating passive components (e.g., resistors, capacitors) directly into PCB layers to reduce size and improve signal performance.

Why it matters: Leads to lower EMI and better vehicle electronics optimization through cleaner layouts.

Built-in Design for Testability (DFT)

Designs now include embedded testing hooks and diagnostics features, easing production testing, and post-deployment diagnostics.

Why it matters: Reduces defects at mass scale and accelerates time-to-volume—critical in automotive supply chains.

How Custom PCB Design Simplifies Vehicle Assembly

In high-volume automotive production, even small inefficiencies can result in significant time and cost losses. That’s why custom PCB design for automotive electronics goes beyond electrical performance and reaches processes like simplifying manufacturing, improving fitment, and revving system integration.

Here’s how our design approach translates into real assembly benefits:

|

Design Feature |

Assembly Benefit |

Our Solution |

|

Optimized Connector Placement |

Faster cable routing, fewer connection errors |

3D mechanical modeling ensures ideal connector orientation for plug-and-play installation |

|

Board Shape Customization |

Perfect fit into complex housing shapes |

Use of rigid-flex PCBs and curved-edge profiling to match enclosure design |

|

Mounting Hole Alignment |

Simplifies chassis or housing integration |

Co-designed with mechanical teams to match fastening points exactly |

|

Pre-tested Module Design |

Minimizes on-line diagnostics |

Built-in self-test features and validation during prototyping |

|

Integrated Heat Dissipation Paths |

Reduces need for extra thermal hardware |

Embedded copper pours and thermal vias for direct heat transfer to chassis |

When PCB design for vehicle electronics is done with manufacturing in mind, it makes development cycles shorter, improves scalability, and delivers better assembly, especially in EV and ADAS projects.

Looking for ways to improve your PCB performance?

Contact usYalantis PCB Design Services: Solving Integration Challenges

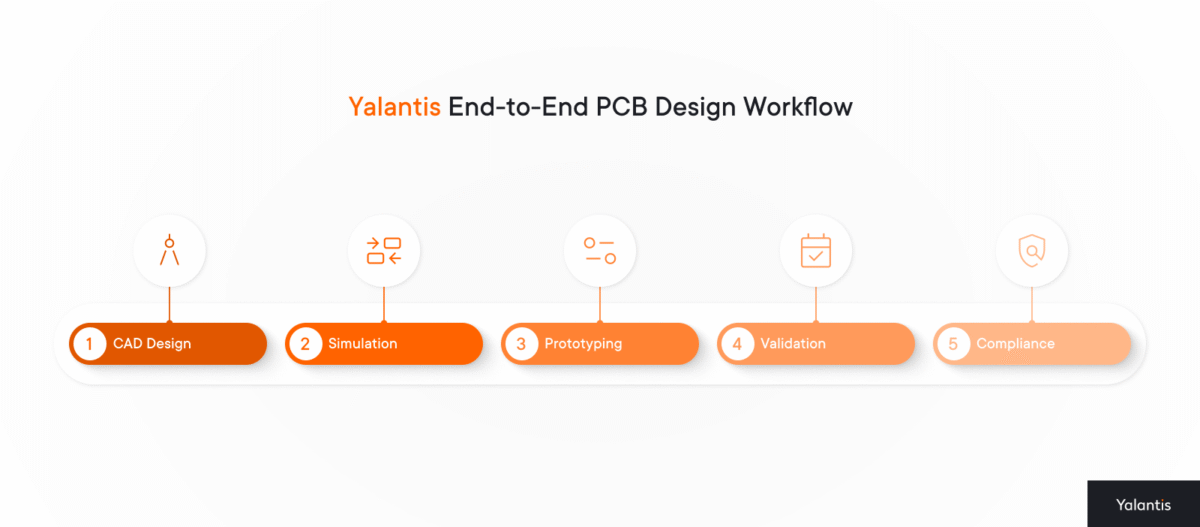

Developing printed circuit boards in vehicle electronics is a high-stakes process where every thermal miscalculation, EMI flaw, or layout mistake can disrupt the entire development lifecycle. At Yalantis, we offer end-to-end PCB design services for automotive electronics for in-vehicle system integration.

From CAD layout and prototyping to compliance documentation and software hardware interfacing, we ensure your automotive circuit board design is functional, manufacturable, testable, and future-ready.

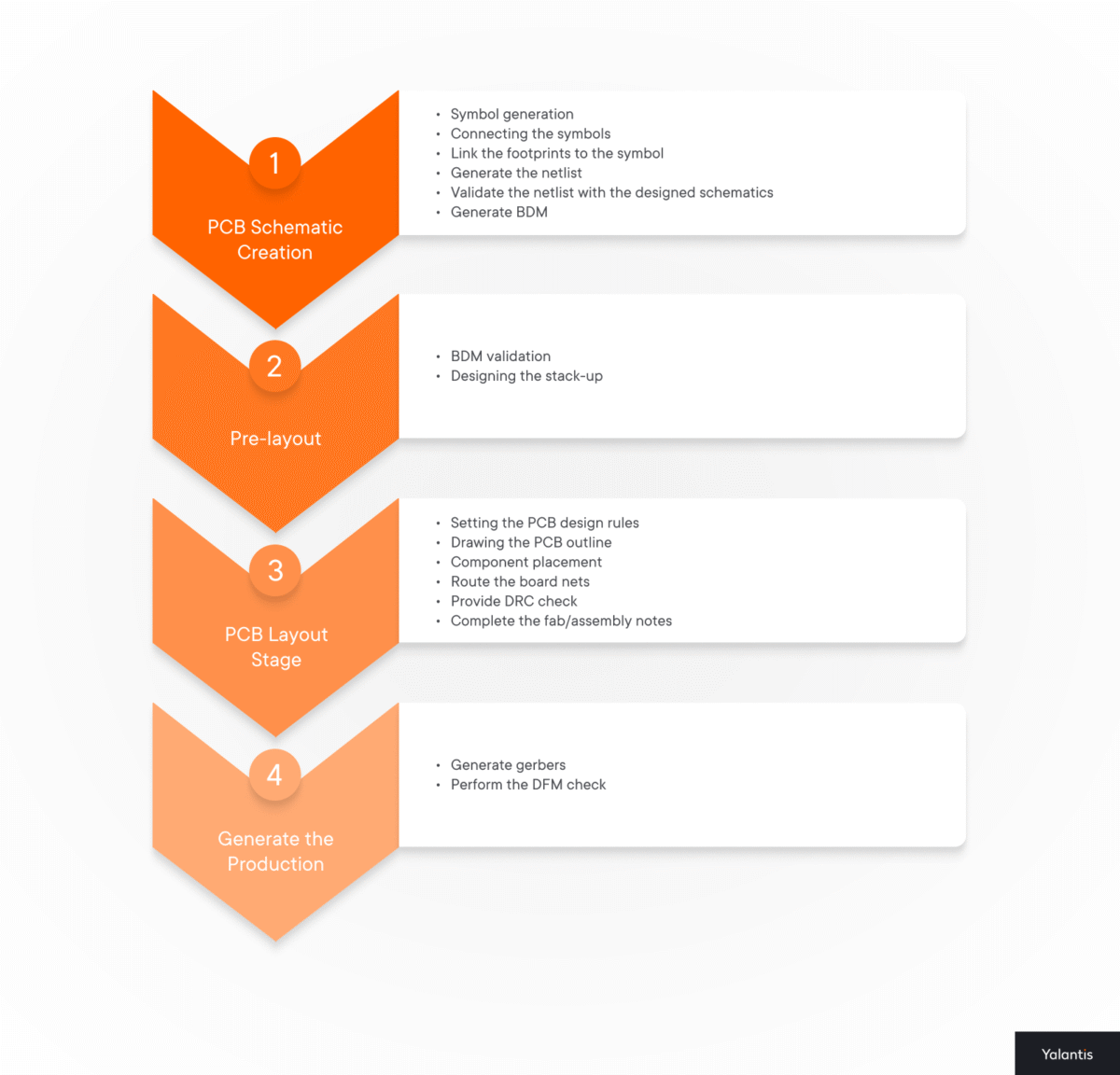

Our End-to-End PCB Design Capabilities

- CAD Layout & Schematic Design

High-quality, standards-compliant board layouts optimized for compact automotive systems and harsh conditions. - Signal Integrity & Thermal Simulation

We perform early-stage simulations of EMI, thermal flow, and power integrity to avoid redesign cycles and improve overall board reliability. - Rapid Prototyping & Validation

Fast iteration cycles to test concepts, validate performance under load, and ensure compatibility between hardware and software. - Automotive Compliance Documentation

Full documentation aligned with IPC-A-610, ISO 26262, and other automotive-grade criteria for functional safety and quality.

|

Challenge |

Our Solution |

|

High thermal loads in EV systems |

Thermal-aware layout + copper pours + simulation of real-world operating loads |

|

EMI risk in ADAS & infotainment |

Shielded traces, ground planning, and AI-driven layout tools to reduce interference |

|

Complex form factor constraints |

Rigid-flex PCBs + enclosure-aware design via CAD/MCAD collaboration |

|

Compliance with safety standards |

Built-in FMEA, safety constraint modeling, and ISO 26262-aligned validation |

|

Software-hardware desync |

Co-design with embedded teams ensures clean handoff and integration readiness |

Why Is PCB So Expensive? (And What Lowers the Cost)

There’s an everyday belief in the automotive world that high-quality automotive PCBs must always come with a high price tag. While it’s true that performance-grade PCBs are not the cheapest component in a vehicle, cost doesn’t have to skyrocket when we focus on providing quality.

Let’s take a look at what actually affects PCB cost and see how to keep it under control.

1. Layer Count

Multilayer PCBs used in ADAS, EV control, and infotainment systems, cost more than single- or double-layer boards due to increased fabrication steps and more complex routing. But stacking too many layers “just in case” is a common mistake.

Smart solution: Optimized stack-up planning during early automotive circuit board design reduces unnecessary layers and keeps performance in check.

2. Materials Used

Materials like FR4 are common and affordable, but higher-performance boards, especially in vehicle PCBs exposed to high frequencies or temperatures, may require progressive laminates like Rogers or polyimide. These increase thermal stability and EMI resistance but also the expense.

Smart solution: avoid over-engineering and match materials to the system’s actual thermal and signal demands.

3. Batch Size and Volume

Prototypes and small-batch runs are naturally more expensive per unit. For low volumes, tooling, setup, and non-recurring engineering costs create a larger share of the price.

Smart solution: Partner with a team that can help move from prototype to production smoothly, allowing better economies of scale with minimal redesign.

4. Layout Complexity

Intricate routing, fine-pitch components, and tight tolerances (especially in PCB design for vehicle control systems) increase production difficulty and inspection time. Some designs may even require specialized equipment to fabricate or test.

Smart solution: Use DFM (Design for Manufacturability) and automated layout tools early to reduce unnecessary complexity.

5. Testing and Validation Level

High-reliability systems require thorough quality control: thermal cycling, vibration testing, X-ray inspection, etc. While essential for safety, these tests do add to the cost.

Smart solution: Design with validation in mind: integrate DFT (Design for Testability) features and pre-validate simulation models, to avoid costly surprises late in development.

Conclusion

It’s fair to say that in the automotive industry we have today reliability, safety, and compliance start at the PCB level. With modern transport’ tighter spaces, greater thermal demands, and increasingly interconnected systems 20th century solutions are no longer enough. The demand for future-proof PCB design for automotive electronics that performs under pressure and scales with your innovation roadmap is here to stay.

Every subsystem relies on precise, standards-aligned PCB engineering. Getting it wrong means delays, recalls, and rising costs. Getting it right means faster time-to-market, lower failure rates, and full confidence in your product lifecycle.

That’s where Yalantis comes in. With deep technical expertise and an end-to-end design process – from CAD and simulation to validation and compliance— we help to reduce risk, accelerate development, and ensure long-term reliability.

FAQ

What is an automotive PCB?

An automotive PCB is a printed circuit board created specifically for vehicle electronics. It supports systems like ADAS, infotainment, BMS, and ECUs by ensuring stable electrical connections, thermal management, and compliance with automotive standards like ISO 26262 and IPC-6012DA.

Does PCB design require coding?

PCB design doesn’t always require traditional coding but involves using specialized software (like Altium or KiCad) for schematic capture and layout. However, scripting or firmware knowledge is helpful for integration with embedded systems or automated design flows.

How many PCBs are in a car?

The majority of modern vehicles can contain over 100 PCBs. These boards power everything from powertrain controllers and battery management systems to infotainment, lighting, and advanced driver-assistance systems, which makes PCB design critical for vehicle trustworthiness.

How much time does it take to design a PCB?

Design time varies based on complexity. An uncomplicated board may take a few days, while a multilayer, automotive-grade PCB can require several weeks for layout, simulation, prototyping, and compliance checks. Early planning helps avoid delays.