IoT-enabled predictive maintenance for logistics uses sensors and data analytics to predict equipment problems before they happen. This approach can reduce unexpected breakdowns by 40% and help vehicles last longer.

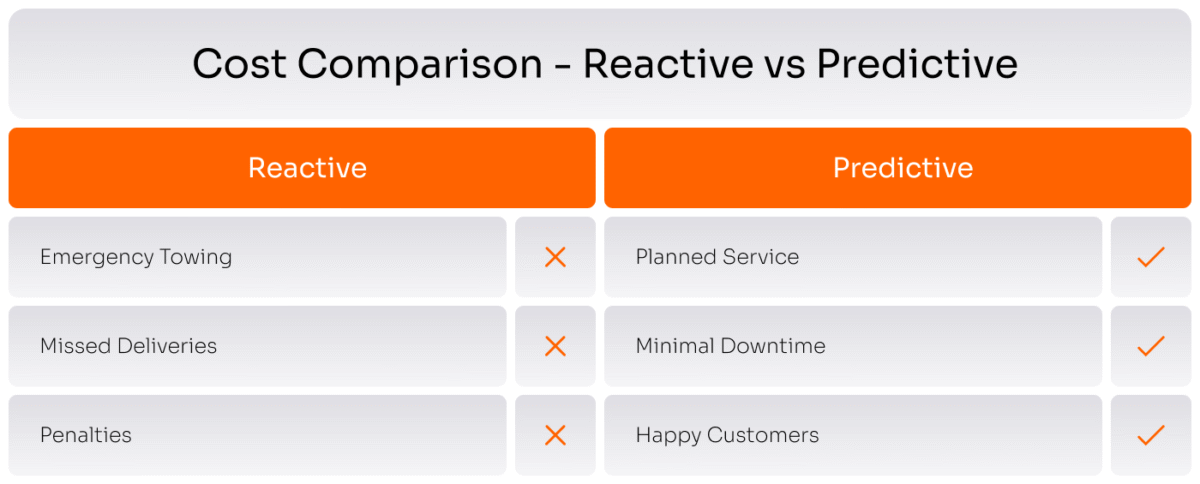

What’s the Real Cost of Reactive Maintenance?

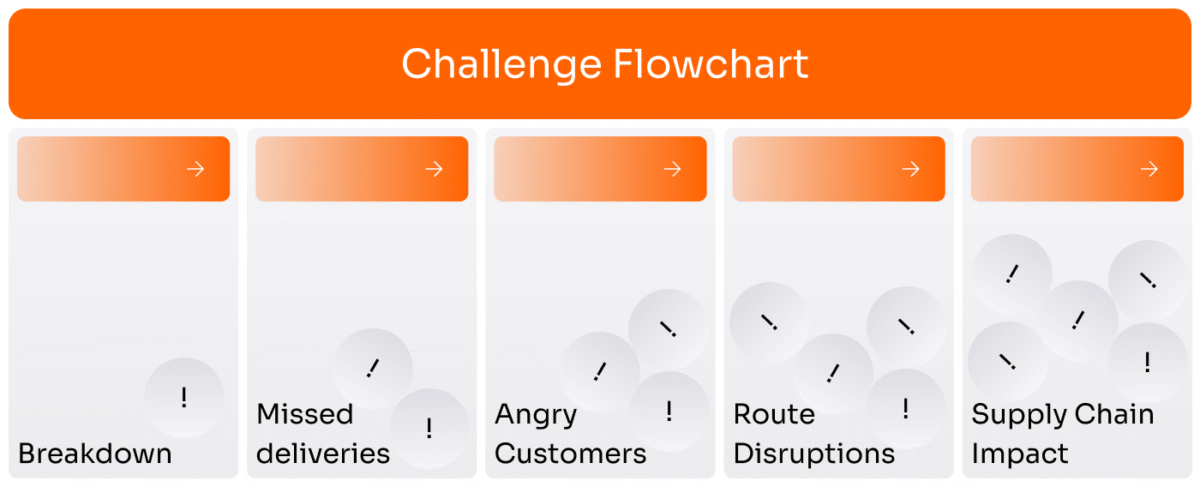

A truck carrying urgent cargo breaks down at 2 AM on the interstate. Emergency towing, missed deliveries, penalties, and angry customers follow. Your team scrambles to reroute loads while calming frustrated clients. This scenario happens daily in logistics, but it’s entirely preventable.

The traditional “fix it when it breaks” approach that dominated the industry creates cascading problems across the entire supply chain. When equipment fails without warning, logistics companies face significant financial hits — a stranded truck costs $500 to $1,000 per day in lost revenue, before adding towing fees, repair costs, and the chaos of rearranging delivery routes.

IoT in transportation and logistics is changing this reality. Companies are getting smarter about maintenance through continuous equipment monitoring instead of waiting for failures or sticking to rigid schedules. Temperature shifts, vibration changes, or pressure drops can alert maintenance teams to problems weeks ahead of breakdowns.

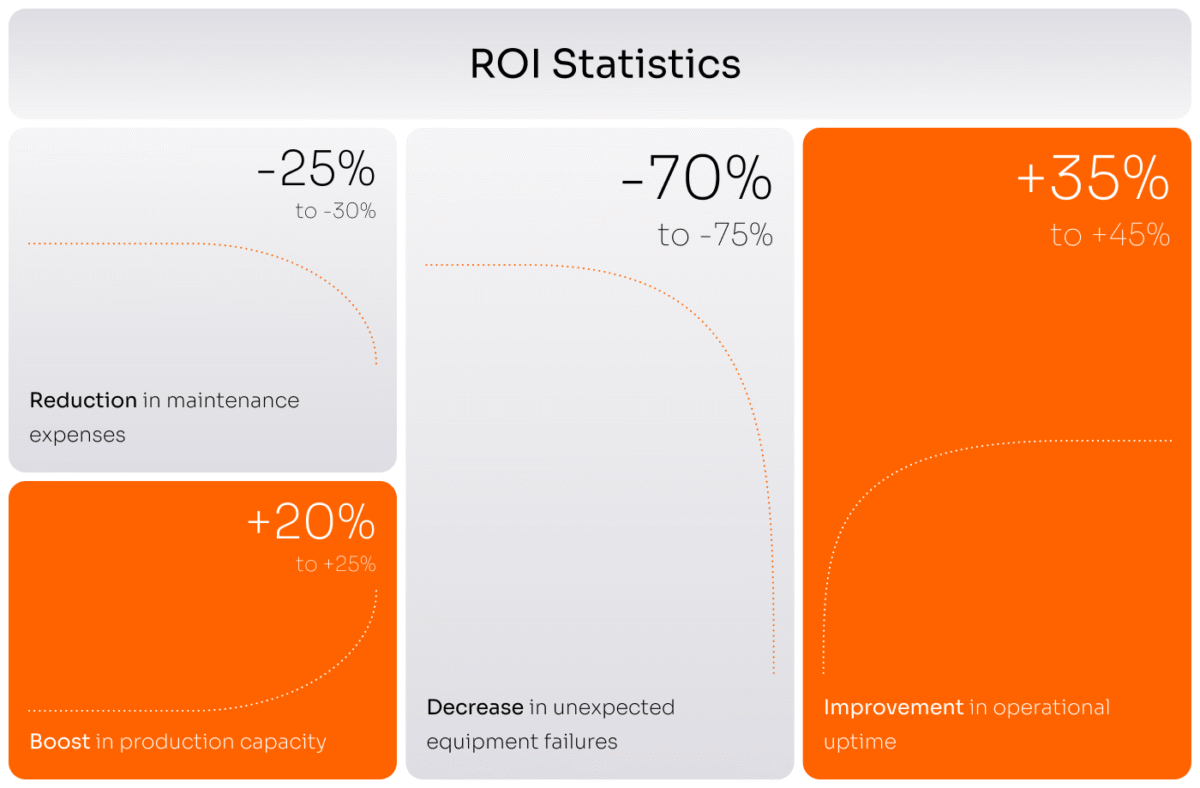

What’s the Business Case for Predictive Maintenance?

The US Department of Energy reports that predictive maintenance programs generate returns 10 times higher than their initial investment. Companies implementing IoT applications in logistics typically see:

- 25% to 30% reduction in maintenance expenses

- 70% to 75% decrease in unexpected equipment failures

- 35% to 45% improvement in operational uptime

- 20% to 25% boost in production capacity

This shift from reactive to predictive models represents one of the most significant advances in fleet management. However, it requires a robust technical infrastructure to handle massive data from IoT devices, simultaneously processing sensor information from hundreds or thousands of units.

Why Does Predictive Maintenance Matter More Than Ever?

As logistics operations grow more complex, traditional maintenance approaches create increasingly severe bottlenecks. The Internet of Things in logistics addresses three critical challenges that plague the industry:

Unplanned Downtime Crisis

When equipment fails without warning, the impact extends beyond a single vehicle. One breakdown disrupts entire delivery routes and creates problems across the supply chain, affecting everything from inventory management to customer deliveries. A single failure can trigger chain reactions for businesses with large fleets that upset customers and disrupt company-wide operations.

Safety Risks from Reactive Approaches

Trucks and equipment operating beyond their optimal state without real-time monitoring create serious safety concerns. Brake problems, tire wear, or engine malfunctions don’t always produce obvious signals until they reach critical stages. Routine maintenance checks overlook gradual deteriorations that could endanger drivers and other road users. Regulatory bodies recognize these risks. In the UK, the DVSA has mandated that all brake performance evaluations use either laden roller brake tests (at least 65% of maximum gross weight) or Electronic Brake Performance Monitoring Systems since April 2025. These requirements acknowledge that traditional inspection methods miss critical safety issues that continuous monitoring can detect.

The Maintenance Timing Dilemma

With traditional maintenance scheduling, companies face impossible choices: service equipment too early when it’s still functioning well, or wait too long and face expensive emergency repairs. Without accurate data on equipment condition, maintenance teams resort to guesswork or overly cautious schedules that waste resources.

How Does IoT Transform Maintenance Strategy?

IoT in logistics and supply chain operations replaces guesswork with real-time vehicle health data. Instead of wondering how equipment is performing or waiting for breakdowns, maintenance teams receive continuous updates from temperature sensors, vibration monitors, and pressure readings.

This constant visibility transforms maintenance scheduling from calendar-driven to condition-based. Rather than servicing equipment at every predetermined interval, regardless of actual condition, teams receive advance warnings about what genuinely needs attention. Modern systems can automatically generate compliance reports and submit them to regulatory bodies, reducing administrative burden while ensuring fleet vehicles spend more time on the road than in maintenance bays. The result is a fundamental shift from rigid schedules to responding to real equipment needs, improving both equipment longevity and operational efficiency.

Ready to reduce downtime and extend your fleet’s operational life?

Let’s discuss how predictive maintenance can transform your logistics operations.

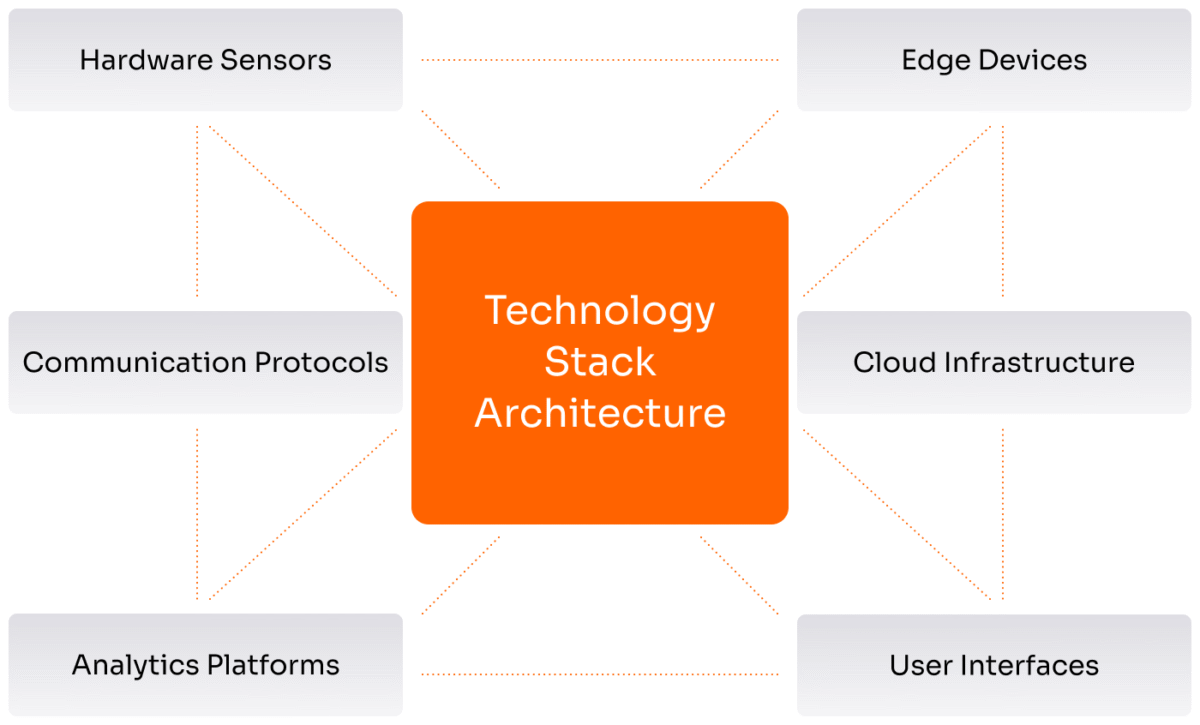

What Are the Core Components of IoT Predictive Maintenance Systems?

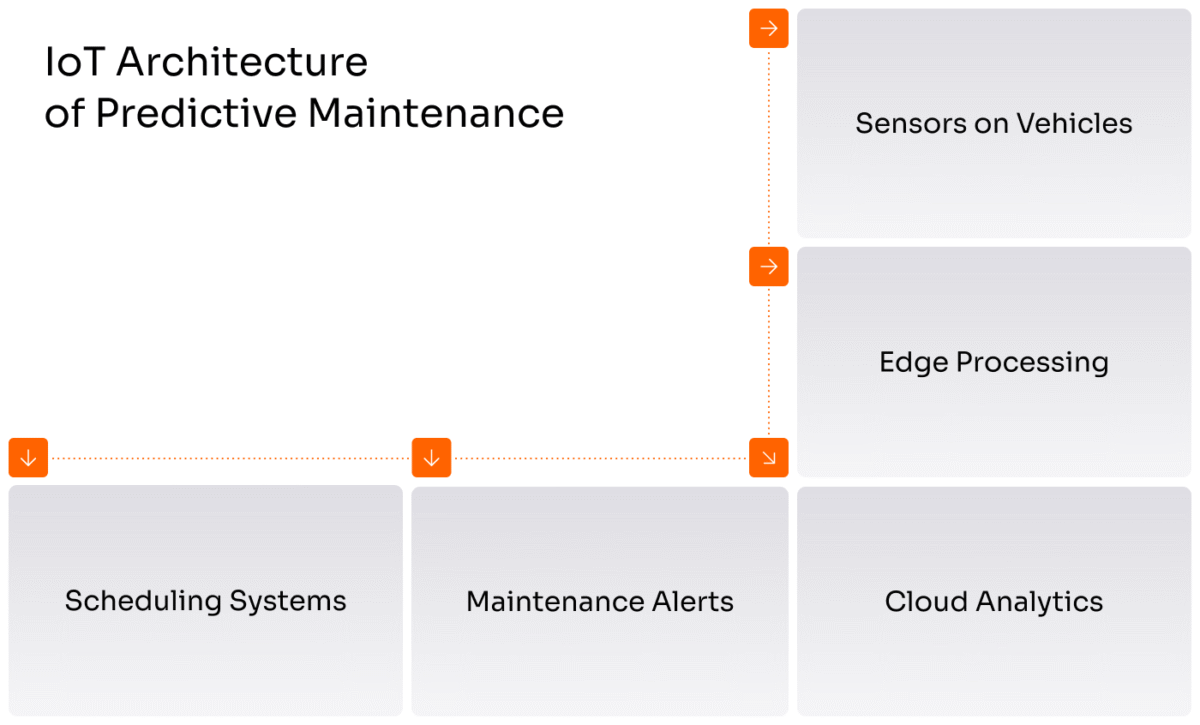

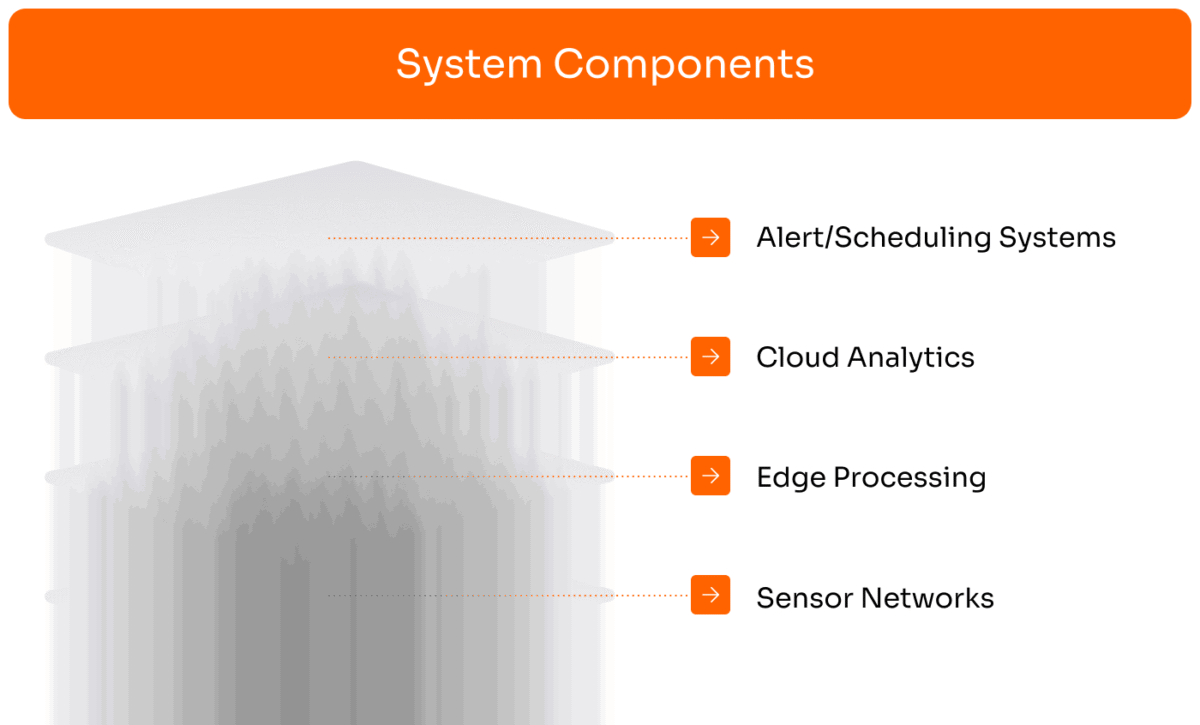

Effective predictive maintenance requires integrating multiple technology layers to collect, process, and act on equipment health data. These systems must handle millions of data points daily from sensor networks across fleets and facilities while balancing immediate responsiveness with long-term analysis needs.

Essential System Elements

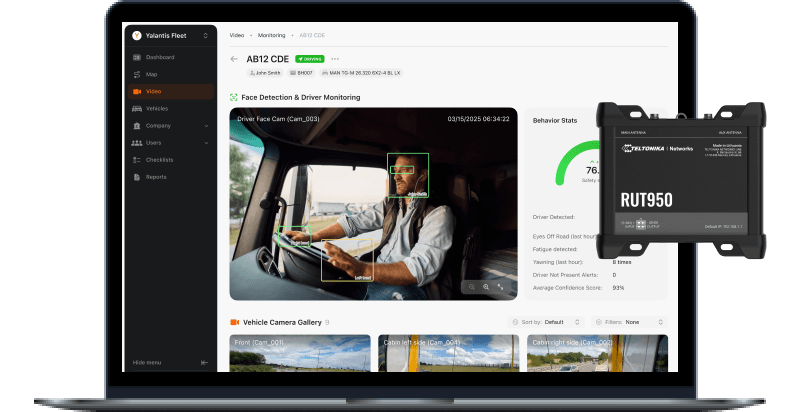

Comprehensive Sensor Networks. The foundation of any predictive maintenance system lies in its sensor infrastructure. Most operational data flows through CANBUS networks and telematics systems from providers like Teltonika, creating a comprehensive picture of vehicle health. Vibration sensors detect wear in engines and drivetrain components before visible signs appear. Temperature monitors catch cooling problems or parts running too hot from friction. Pressure sensors identify leaks or performance drops in hydraulic and air systems. Oil analysis sensors detect contamination and metal particles that indicate component wear.

Edge Processing Capabilities. Edge devices handle the critical first stage of data processing, filtering sensor information, and performing initial analysis before transmission to central systems. These units eliminate background noise, enable immediate responses to critical problems, and manage communication between sensors and cloud infrastructure. Edge processing reduces bandwidth requirements while enabling split-second decision-making essential for preventing equipment failures.

Advanced Data Analytics Platforms. Cloud-based analytics systems use machine learning to identify patterns and predict failures from historical and real-time data. Machine learning models process the continuous stream of CANBUS data and telematics information to build failure prediction algorithms. These models analyze thousands of variables, from engine performance metrics to brake system telemetry, learning to recognize the subtle patterns that precede component failures. The entire predictive maintenance approach depends on these algorithms, which forecast equipment needs weeks before problems occur, transforming raw sensor data into precise maintenance schedules. These platforms build custom prediction models for each piece of equipment, accounting for usage patterns, operating conditions, and maintenance history. The application of IoT in logistics enables sophisticated analysis that continuously improves prediction accuracy as more information becomes available.

Integrated Alert and Scheduling Systems. Turning predictions into actionable maintenance requires seamless integration with existing fleet management software. These systems automatically generate work orders, schedule service appointments, order necessary parts, and assign technicians based on predicted failure timelines and operational priorities.

The Role of Rust in Backend Development for IoT Systems

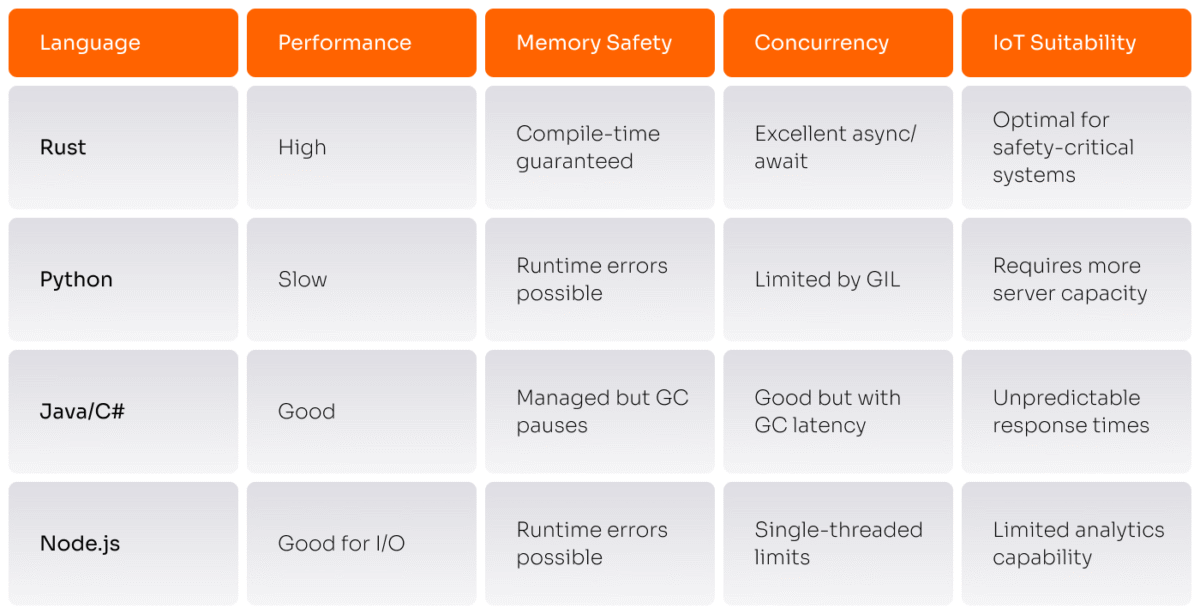

Modern IoT predictive maintenance systems require backend infrastructure that processes massive sensor data volumes while maintaining reliability. Rust has emerged as a strong choice for these mission-critical systems, combining memory safety with high performance.

Rust’s Edge and Cloud Capabilities

IoT systems handle millions of concurrent sensor readings from fleet vehicles. Rust eliminates memory management risks that can crash systems processing real-time streams – memory leaks or buffer overflows could mean missing critical brake failure alerts. The language’s ownership system prevents these errors at compile time, enabling IoT backends to run for months without crashes while processing high-frequency sensor data.

Rust’s async capabilities allow single servers to efficiently handle thousands of concurrent sensor connections. Rust’s efficiency enables complex analytics on resource-constrained hardware for edge computing in vehicles or warehouses, requiring more powerful systems with other languages.

Performance and Cost Advantages

Rust applications consume 50-70% less memory than equivalent Java implementations while delivering superior performance. This reduces cloud computing costs for companies processing large IoT data volumes. Edge devices can perform sophisticated local processing without requiring expensive hardware upgrades.

Comparison with Other Backend Technologies

Python is slower, which creates problems with fast-incoming sensor data, so you need more computing power (more servers) to keep up. Java and C# offer good performance, but their garbage collection can introduce latency spikes that delay critical maintenance alerts. Node.js handles concurrent connections well, but its single-threaded nature limits CPU-intensive analytics that predictive algorithms require.

Rust provides memory safety and concurrency without these trade-offs. It is particularly suitable for safety-critical logistics applications where system failures directly impact operational costs and driver safety. Learn more about building robust IoT backends with Rust development services.

What Real-World Benefits and ROI Can You Expect?

IoT-enabled predictive maintenance for logistics delivers measurable results that typically pay for implementation costs within 12-18 months. The system’s effectiveness improves as machine learning algorithms adapt to specific equipment patterns and operating conditions.

Dramatic Downtime Reduction

Companies implementing comprehensive IoT and logistics solutions see 20-40% reductions in unplanned downtime. With 2-4 weeks’ warning of potential issues, maintenance teams can schedule repairs during planned downtime instead of dealing with emergency breakdowns during peak operational periods.

Extended Equipment Lifespan

Equipment monitored through IoT in logistics systems lasts 15-25% longer when problems are identified and addressed early. Engines maintain optimal performance when cooling issues receive immediate attention, and transmissions avoid catastrophic failure when sensors detect early wear patterns before major damage occurs.

Predictable Maintenance Costs

Organizations eliminate surprise repair bills and emergency service premiums by shifting to proactive maintenance scheduling. Teams can plan work schedules, order parts in advance, and coordinate service activities around operational requirements, creating predictable budget allocations for maintenance activities.

Enhanced Safety Standards

IoT devices provide precise, continuous measurements that eliminate inconsistency and oversight risks. This data-driven approach ensures vehicle health monitoring meets safety requirements while reducing liability exposure from equipment-related accidents.

Need a fast, secure backend for your IoT project?

Explore how we use Rust for high-performance logistics systems at Yalantis.

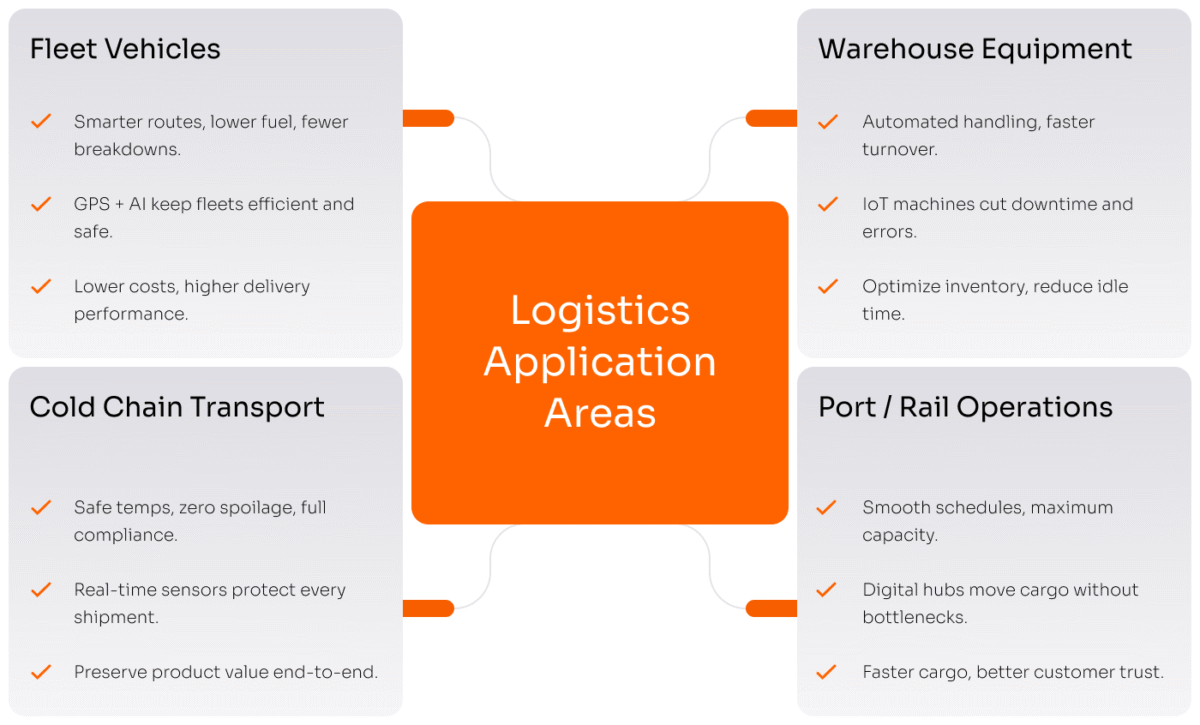

Where Can You Apply Predictive Maintenance Across Logistics Operations?

Internet of things transportation solutions work across all major logistics sectors, with each area offering specific opportunities to prevent costly failures and optimize operations.

Fleet Vehicle Monitoring

Most companies begin predictive maintenance implementation with trucks and delivery vans, which typically deliver the highest return on investment. Engine sensors track performance decline and predict maintenance needs, brake monitors detect worn components before they become safety hazards, and tire pressure systems identify slow leaks that could cause highway incidents.

Warehouse Equipment Optimization

Monitoring conveyor belts, forklifts, and automated storage systems prevents costly operational shutdowns. Vibration sensors detect bearing problems before motors fail, temperature readings identify overheating hydraulic systems, and electrical monitoring prevents motor burnouts that disrupt warehouse operations.

Cold Chain Management

Refrigerated transport and cold storage require continuous monitoring since temperature control directly impacts cargo value. Systems track compressor performance, detect insulation failures, and identify control problems that could spoil entire shipments. For temperature-sensitive goods, predictive maintenance prevents losses that can eliminate months of profit margins.

Port and Rail Operations

Heavy equipment in ports and rail yards operates under harsh conditions where breakdowns create major bottlenecks. Monitoring cranes, railcar tracking equipment, and container handling systems prevents expensive delays and ensures smooth supply chain operations.

How Do You Build Scalable Implementation Strategies?

Moving from concept to production-ready predictive maintenance requires systematic planning and technical decisions that impact system performance, reliability, and scalability for years. Success depends on understanding both technical requirements and operational workflows.

Strategic Equipment Prioritization

Begin implementation by focusing on assets based on replacement cost, operational impact, and failure consequences. A truck hauling high-value pharmaceuticals requires more comprehensive monitoring than a vehicle making routine local deliveries. This prioritization ensures maximum return on initial investment while building organizational confidence in the technology.

Sensor Selection and Deployment

Balance monitoring comprehensiveness with installation constraints and budget limitations. Wireless sensors offer easy installation but require battery management strategies, while wired sensors provide more reliable data transmission but involve higher installation costs and complexity.

Scalable Infrastructure Design

Build data processing systems that handle current sensor volumes while accommodating fleet expansion. Design architectures that work effectively for 50 vehicles today but can scale to 500 without major system overhauls. This scalability is essential in logistics, where fleet growth is constant and rapid.

Intelligent Analytics Development

Develop algorithms that distinguish between normal equipment variations and potential problems. Systems must account for different usage patterns, seasonal operating conditions, and individual equipment characteristics to provide accurate maintenance alerts without overwhelming teams with false positives.

User-Centric Interface Design

Create dashboards and mobile applications that transform complex data into actionable maintenance decisions. Interfaces should highlight critical information without overwhelming users, while integration with parts ordering and scheduling systems ensures seamless workflow management.

What Technology Stack Decisions Impact System Success?

Programming Language Selection

Choose development platforms that reliably handle massive sensor data volumes. Languages like Rust have gained popularity for IoT logistics applications because they eliminate common memory management errors that can crash systems processing real-time data streams. This reliability is crucial in logistics, where system failures directly impact operational safety and costs.

Architecture Balance

Design systems that balance immediate processing needs with long-term analysis capabilities. Edge processing enables rapid response to critical situations, cloud systems provide computational power for complex machine learning, and long-term storage supports trend analysis over extended periods.

Integration Capabilities

Ensure seamless data flow between predictive maintenance insights and daily operations through robust APIs and data protocols. Compatibility with existing fleet management, ERP, and maintenance software eliminates manual data handoffs and ensures insights translate directly into operational improvements.

Our experience extends to building comprehensive IoT solutions for clients like RAKwireless, a leading manufacturer of IoT devices. We developed a scalable, cloud-based platform for them to remotely manage and monitor thousands of IoT gateways and sensors. This solution enabled enterprise clients to onboard devices, configure networks, and view real-time status updates, significantly enhancing their operational control and enabling seamless scalability from small to large IoT deployments.

Curious what it would take to implement predictive maintenance in your environment?

Connect with our IoT systems architects to explore your specific requirements.

What Does the Future Hold for IoT in Logistics?

The convergence of IoT and logistics expands operational efficiency and cost reduction possibilities. As sensors become more sophisticated and data analytics grow more powerful, predictive maintenance capabilities will continue advancing beyond current implementations.

Organizations building strong technical foundations now position themselves to capitalize on emerging developments like autonomous maintenance scheduling, integrated supply chain optimization, and AI-driven operational decision-making. These advances will further reduce human intervention requirements while improving prediction accuracy and operational efficiency.

Companies implementing comprehensive IoT applications in logistics gain competitive advantages through improved reliability, reduced operational costs, and enhanced safety standards. The technology represents an investment in operational excellence that delivers ongoing returns through reduced downtime, extended equipment life, and predictable maintenance operations.

At Yalantis, we help logistics companies navigate this transformation by building custom predictive maintenance platforms that integrate into existing operations while delivering the performance and scalability required for long-term success. Our expertise in Rust development and IoT solutions for logistics enables us to create systems that meet the demanding requirements of modern fleet operations.

Ready to reduce downtime and extend your fleet’s operational life?

Contact our IoT specialists today to discuss how predictive maintenance can transform logistics operations.

FAQ

How much historical data is needed to build accurate predictive models?

Most predictive maintenance systems require 6-12 months of operational data to develop reliable failure prediction models. However, you can start seeing benefits from anomaly detection and trend analysis within the first 30-60 days of data collection. The key is beginning data collection immediately while gradually refining predictive accuracy as more historical patterns become available.

How long does it typically take to develop a custom predictive maintenance system?

A complete predictive maintenance platform typically requires 6-9 months for development and deployment, depending on fleet size and system complexity. This includes sensor selection and installation, backend development, analytics pipeline creation, and user interface design. The timeline can be shortened by leveraging existing IoT infrastructure or initially focusing on specific high-priority assets.

Can we integrate a predictive maintenance solution into our current fleet management platform?

Modern predictive maintenance systems are designed with integration capabilities from the ground up. APIs and data exchange protocols enable seamless communication with existing fleet management, ERP, and maintenance management systems. The integration process typically adds 2-4 weeks to the implementation timeline but ensures that predictive insights fit naturally into existing operational workflows.

How do you ensure the system remains scalable and adapts to future needs?

Scalability requires careful architectural planning, including cloud-native design patterns, microservices architecture, and modular sensor networks. We design systems using technologies like Rust that provide the performance headroom needed for growth, while container-based deployment enables efficient resource scaling. Regular architecture reviews ensure the system continues meeting performance requirements as fleet size and monitoring scope expand.

What are the typical costs involved in a custom predictive maintenance platform?

Investment requirements vary significantly based on fleet size, monitoring scope, and integration complexity. Hardware costs (sensors, gateways) typically range from $500-2,000 per vehicle, while software development and deployment costs scale with system complexity. Most companies see positive ROI within 12-18 months through reduced downtime and maintenance cost optimization. We provide a detailed cost-benefit analysis during the planning phase to ensure visibility of expected returns.